The landscape of manufacturing is evolving rapidly, driven by advances in digital technology and the need for greater flexibility. On demand 3D printing is at the forefront of this transformation, offering manufacturers the ability to produce parts, prototypes, and products exactly when and where they are needed. This approach eliminates the constraints of traditional mass production, enabling businesses to respond quickly to changing market demands, reduce waste, and streamline supply chains.

By leveraging additive manufacturing, companies can move from design to finished part in a matter of hours or days, rather than weeks. This shift is not only making production more agile but also opening up new possibilities for customization, rapid prototyping, and localized manufacturing. For those interested in improving the quality of their printed components, exploring sanding and finishing 3D prints can further enhance the end result.

Understanding the Basics of On Demand 3D Printing

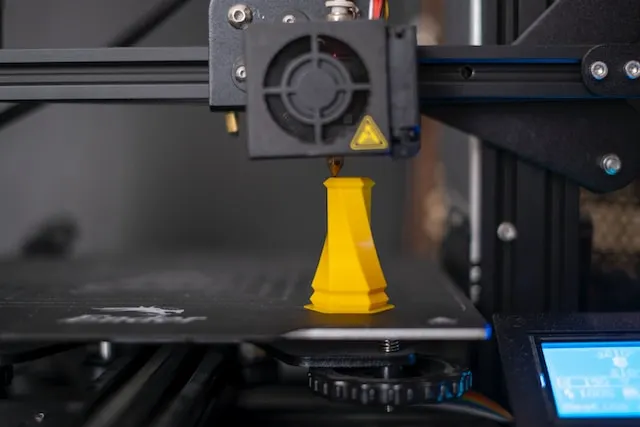

At its core, on demand 3D printing is a digital manufacturing process that creates objects layer by layer from a digital file. Unlike traditional subtractive methods, which remove material from a solid block, additive manufacturing builds up the part, resulting in less waste and greater design freedom. This technology is used across a range of industries, from aerospace and automotive to healthcare and consumer goods.

The process typically begins with a CAD (computer-aided design) model, which is then sliced into thin layers. The printer reads these instructions and deposits material—such as plastic, resin, or metal—precisely where needed. Because the process is digital, it is easy to make adjustments, iterate on designs, and produce unique or low-volume parts without the need for expensive tooling.

Key Benefits for Modern Manufacturing

The adoption of on demand 3D printing brings several significant advantages to manufacturers:

- Reduced Lead Times: Parts can be produced within hours, allowing for rapid prototyping and faster product development cycles.

- Lower Inventory Costs: Instead of storing large quantities of spare parts, companies can print components as needed, minimizing warehousing expenses.

- Customization: Each item can be tailored to specific requirements without additional cost or complexity.

- Supply Chain Resilience: Localized production reduces reliance on global shipping and helps mitigate disruptions.

- Sustainability: Additive manufacturing uses only the material required for each part, resulting in less waste compared to traditional methods.

These benefits are especially valuable in industries where agility and innovation are critical. For example, in healthcare, custom prosthetics and implants can be produced quickly to meet individual patient needs. In automotive and aerospace, engineers can rapidly iterate on designs and produce lightweight, complex components that would be difficult or impossible to manufacture using conventional techniques.

How to Integrate Additive Manufacturing into Your Workflow

For businesses considering the shift to digital fabrication, the transition can be straightforward with the right planning. Here are some practical steps to get started:

- Assess Your Needs: Identify which parts or products could benefit from on demand production. Look for items that require frequent design changes, have unpredictable demand, or are costly to store.

- Select the Right Technology: Choose a 3D printing process and material that matches your application. Fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) each have unique strengths.

- Develop Digital Models: Use CAD software to create or adapt designs for additive manufacturing. Many platforms, such as Autodesk’s 3D printing solutions, offer tools specifically for this purpose.

- Test and Iterate: Print prototypes to evaluate fit, function, and finish. Refine your designs based on feedback and testing.

- Scale Production: Once the process is validated, ramp up production as needed. Digital files can be shared across locations, enabling distributed manufacturing.

Integrating additive manufacturing doesn’t mean replacing all traditional methods. Instead, it complements existing processes, offering a flexible option for specific parts or production runs. For those looking to improve the surface quality of their prints, learning about post processing 3D prints can be highly beneficial.

Applications and Use Cases Across Industries

The versatility of on demand 3D printing is evident in its wide range of applications. Some notable examples include:

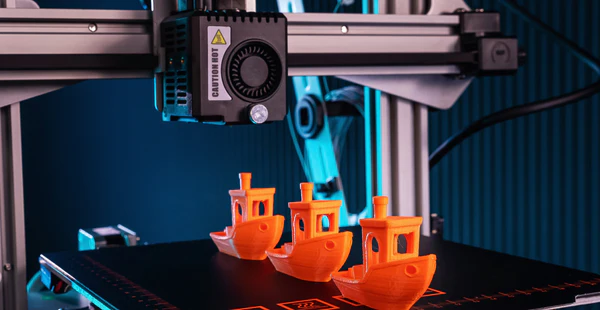

- Rapid Prototyping: Designers and engineers can quickly produce and test new concepts, reducing time to market.

- Tooling and Jigs: Custom fixtures and tools can be printed as needed, improving efficiency on the factory floor.

- Replacement Parts: Spare components for machinery or consumer products can be manufactured on-site, minimizing downtime.

- End-Use Products: Short-run or highly customized items, such as medical devices or personalized consumer goods, are now feasible.

As more companies adopt digital manufacturing, the ecosystem continues to grow. New materials, improved printer capabilities, and advanced software are making it easier than ever to produce high-quality, functional parts on demand.

Challenges and Considerations for Digital Fabrication

While the advantages are substantial, there are also challenges to address when implementing on demand 3D printing in a manufacturing environment:

- Material Limitations: Not all materials are suitable for every application, and some may not match the mechanical properties of traditionally manufactured parts.

- Quality Control: Ensuring consistent results requires careful calibration and process monitoring.

- Post-Processing: Many parts require additional finishing steps, such as painting 3D printed models or smoothing surfaces, to achieve the desired appearance and performance.

- Intellectual Property: The ease of sharing digital files raises concerns about design security and unauthorized reproduction.

Addressing these issues often involves investing in staff training, quality assurance systems, and secure digital workflows. For those new to the technology, starting with low-risk applications and gradually expanding usage can help build confidence and expertise.

Future Trends in On Demand Production

The future of manufacturing is increasingly digital, with on demand 3D printing playing a central role. Some emerging trends include:

- Distributed Manufacturing: Networks of printers in multiple locations enable localized production, reducing shipping times and costs.

- Advanced Materials: New composites and metal powders are expanding the range of applications.

- Automation: Integration with robotics and AI is streamlining workflows and reducing manual intervention.

- Mass Customization: The ability to produce unique items at scale is transforming markets from footwear to automotive interiors.

As these trends continue, manufacturers who embrace additive manufacturing will be well positioned to adapt to changing customer needs and global market dynamics. For those seeking to optimize their prints, understanding how to prevent warping in prints is a valuable resource.

Frequently Asked Questions

What types of materials can be used in on demand 3D printing?

A wide variety of materials are available, including plastics (such as PLA, ABS, and PETG), resins, metals, ceramics, and even composites. The choice depends on the application, required strength, and desired finish.

How does on demand 3D printing reduce manufacturing costs?

By producing parts only when needed, companies can minimize inventory, reduce waste, and avoid the costs associated with traditional tooling and storage. Digital workflows also enable faster design changes and lower the barrier for customization.

Is additive manufacturing suitable for large-scale production?

While traditionally used for prototyping and small batches, advances in printer speed and automation are making it increasingly viable for larger production runs, especially for complex or customized parts.

What post-processing steps are required for 3D printed parts?

Common post-processing steps include sanding, painting, and finishing to improve surface quality and durability. For more details, see our guide on post processing 3D prints.