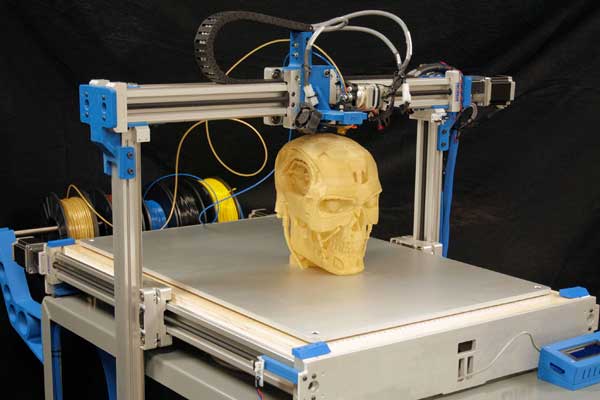

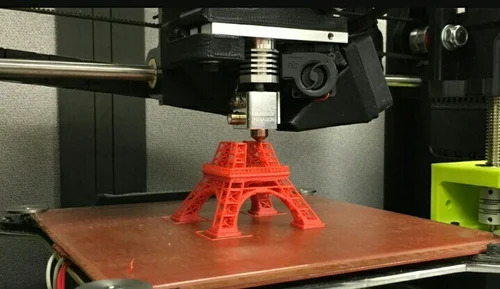

Wood filament printing has opened up new creative possibilities for makers, designers, and hobbyists who want to produce objects with the look and feel of real wood. By blending PLA with fine wood particles, these specialty filaments allow 3D printers to create parts that mimic the grain, color, and even scent of natural timber. However, achieving truly lifelike textures and finishes requires more than just loading a spool and hitting print. This article provides practical advice for getting the most out of wood-based filaments, from printer settings to post-processing techniques.

If you’re interested in sustainable or environmentally conscious fabrication, you may also want to explore topics like eco friendly 3D printing and the use of recycled filaments for 3D printing. These approaches can complement your work with wood-based materials, helping you reduce waste and environmental impact.

Understanding Wood-Based 3D Printing Filaments

Wood-infused filaments are typically a composite of PLA (polylactic acid) and finely ground wood fibers, usually making up 20–40% of the blend. This combination allows standard FDM/FFF 3D printers to extrude the material just like regular PLA, but with the added benefit of a wood-like appearance and tactile feel. The result is a print that can be sanded, stained, or painted to further enhance its resemblance to carved or milled wood.

There are several brands and types of wood filaments available, each offering different wood species (such as pine, bamboo, or cedar) and color variations. Some even emit a subtle wood aroma during printing. For a broader overview of available materials, see this 3D printing materials overview.

Printer Preparation and Settings for Wood Filament

To achieve optimal results with wood-based filaments, it’s important to fine-tune your printer’s hardware and software settings. Here are some key considerations:

- Nozzle Size: Use a nozzle with a diameter of at least 0.4 mm, though 0.5–0.6 mm is preferred. The wood particles can clog smaller nozzles.

- Temperature: Start with the filament manufacturer’s recommended range, usually 190–220°C. Higher temperatures can darken the print, simulating wood grain variation.

- Print Speed: Reduce print speed to 40–60 mm/s. Slower speeds help prevent clogs and improve surface finish.

- Retraction: Lower retraction settings minimize the risk of jams, as wood particles can accumulate in the hotend.

- Cooling: Enable part cooling fans to improve overhangs and reduce stringing.

Achieving Realistic Wood Textures and Grain

Creating authentic wood-like surfaces with wood filament printing involves both careful slicing and thoughtful post-processing. Here are some strategies to help your prints stand out:

- Layer Height: Use thicker layers (0.2–0.3 mm) to accentuate the layered “grain” effect, mimicking the look of real wood.

- Variable Temperature: Intentionally adjusting the nozzle temperature during the print can produce subtle color variations, simulating natural wood grain patterns.

- Orientation: Align your model so that the layer lines run in the same direction as the desired wood grain.

- Surface Texture: Some slicers offer “fuzzy skin” or similar features, which add randomness to the outer surface, enhancing the tactile wood effect.

For more advanced users, consider designing your model with engraved or embossed grain patterns, or using multi-color wood filaments to further enhance realism.

Post-Processing for Authentic Finishes

Post-processing is where wood-based prints truly come to life. Here are some finishing techniques to try:

- Sanding: Use fine-grit sandpaper to smooth layer lines and reveal the wood fibers. Sanding also prepares the surface for staining or painting.

- Staining: Apply wood stain or diluted acrylic paint to deepen color and highlight grain. Test on a scrap piece first, as absorption varies by filament brand.

- Sealing: Finish with a clear wood sealer or polyurethane to protect the surface and enhance the wood-like sheen.

- Burnishing: Rubbing the print with a soft cloth can bring out a subtle luster, similar to polished wood.

These steps can help your prints resemble carved or turned wooden objects, making them suitable for display pieces, gifts, or functional parts.

Common Challenges and Solutions in Wood Filament Printing

While working with wood-filled filaments is rewarding, it does come with unique challenges. Here are some common issues and how to address them:

- Nozzle Clogs: Use a larger nozzle and clean it regularly. Avoid leaving the hotend idle with wood filament loaded, as this can cause jams.

- Brittleness: Wood-based prints can be more brittle than pure PLA. Avoid thin or delicate features, and consider increasing wall thickness.

- Stringing: Fine-tune retraction and temperature settings. Lowering print temperature and increasing travel speed can help.

- Inconsistent Color: Embrace the natural variation, or use temperature changes to control the effect.

For a deeper dive into 3D printing techniques and troubleshooting, you can consult comprehensive resources like the 3D printing technology guide from Hubs.

Environmental Considerations and Alternatives

Many users choose wood-based filaments for their eco-friendly appeal. PLA itself is derived from renewable resources, and the addition of wood fibers can reduce the reliance on petroleum-based plastics. For those seeking even greener options, consider exploring biodegradable 3D printing materials or other sustainable practices.

If you’re comparing materials for your next project, you might also find value in this PLA vs ABS comparison to better understand the strengths and weaknesses of each.

FAQ: Wood-Based 3D Printing

Can I use any 3D printer with wood-based filaments?

Most FDM/FFF printers that can handle PLA are compatible with wood-filled filaments. However, it’s best to use a printer with a hardened steel or wear-resistant nozzle, as the wood particles can accelerate nozzle wear.

Is it possible to stain or paint wood filament prints?

Yes, you can stain, paint, or even varnish prints made from wood-based filaments. Sanding the surface first helps with absorption and adhesion, allowing you to achieve a more authentic wood finish.

How do I prevent clogs when using wood-infused filaments?

Use a larger nozzle (0.5 mm or above), lower retraction settings, and avoid leaving the hotend heated with filament inside for extended periods. Regular maintenance and cleaning are also important.

Are wood-based filaments biodegradable?

Most wood-filled filaments use PLA as a base, which is biodegradable under industrial composting conditions. The addition of wood fibers can enhance the eco-friendly profile, but always check the manufacturer’s details for specifics.

Wood filament printing offers a unique way to combine the versatility of 3D printing with the timeless appeal of natural wood. By understanding the material, optimizing your printer settings, and experimenting with finishing techniques, you can create objects that are both beautiful and functional. Whether you’re crafting decorative pieces or practical parts, these tips will help you achieve results that stand out for their realism and quality.