In today’s rapidly evolving world, understanding offset printing is key for businesses aiming to produce high-quality materials. So, what is offset printing, and why is it considered a cornerstone of commercial printing?

Offset printing, also known as offset lithography, is a widely-used printing technique where the inked image is transferred from a plate to rubber blanket, then onto the printing surface. It is called ‘offset’ because the ink is not directly applied to the paper. Understanding this process can unveil the artistic and technical brilliance it offers.

Understanding the Basics of Offset Printing

Fundamentally, offset printing is leveraged for mass production. It yields consistent superior prints faster and at a lower cost than traditional pressing techniques. With today’s technological advancements, what makes offset printing special is its adaptability and precision.

History of Offset Printing

The evolution of offset printing is remarkable. Originating in the early 20th century, it revolutionized commercial printing. This process, inspired by traditional lithography, was developed to overcome the limitations faced by earlier printing techniques.

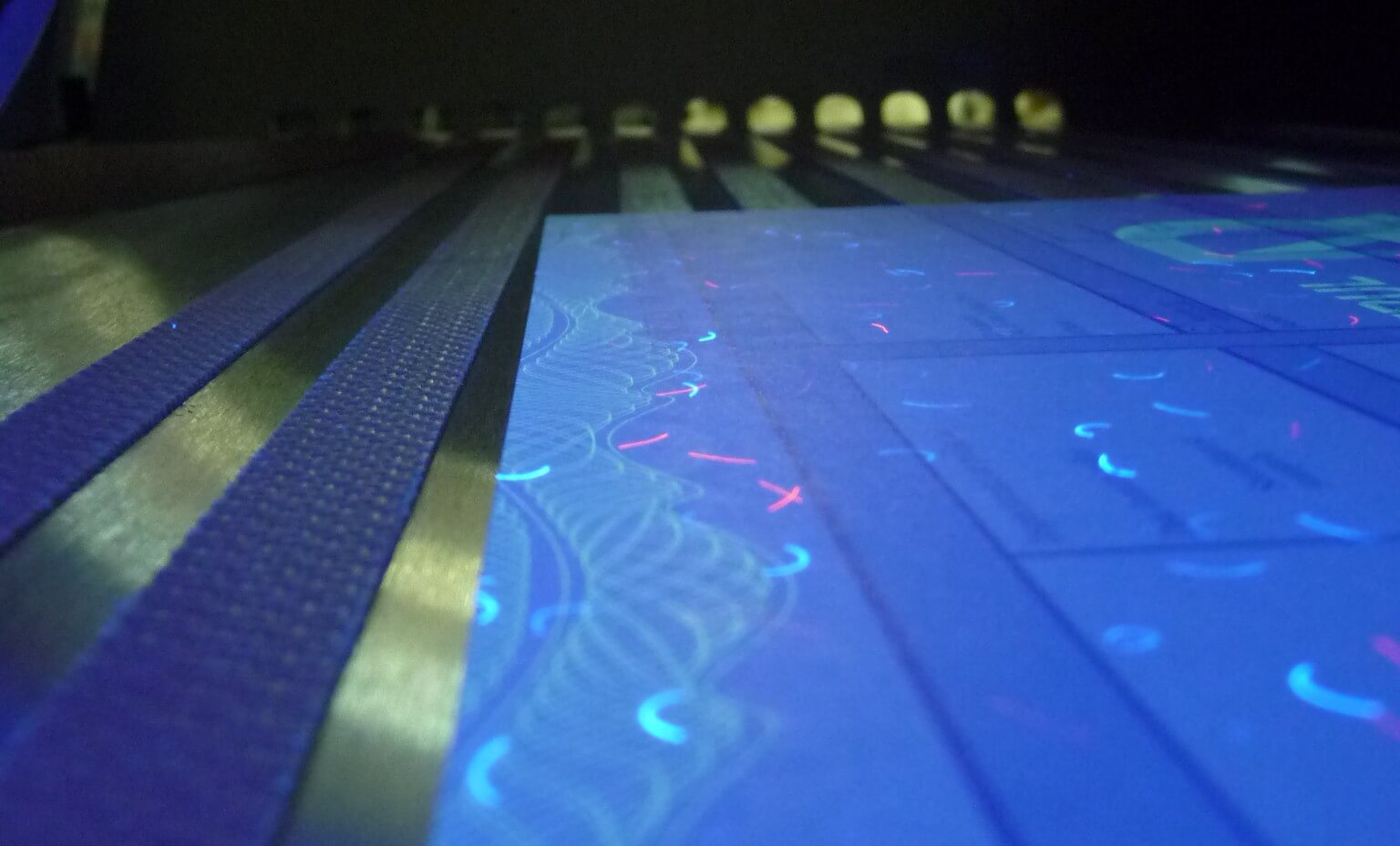

Offset Printing Plates

Plates play a crucial role in offset printing. Generally made from aluminum, each plate is etched with the image that is to be printed, ensuring precision in transferring details.

The Role of Rubber Blankets

The rubber blanket acts as a damper that transfers the ink from the plate to the paper efficiently. The resilience and flexibility of the rubber provide even pressure distribution, improving print quality.

How Does Offset Printing Work?

The process involves several key stages, each indispensable for the integrity of the final product. It begins with preparing the plates, setting up the press, and finally, the printing itself.

Pre-Press Preparation

The pre-press involves creating and setting up plates with the desired text and images. This step is crucial, as even the smallest error can affect thousands of copies.

Ink Application

Ink choice impacts the final print’s vibrancy and quality. During this phase, the ink is applied to the plate, picked up by the rubber blanket, and then transferred to the paper.

Paper Feed

The paper feed mechanism ensures that sheets pass through the press seamlessly, affecting the speed and quality of the print output.

Benefits of Offset Printing

There are numerous advantages to using offset printing. It’s known for producing higher image quality, cost-effectiveness for large print runs, and the ability to print on a wide range of materials and finishes.

Quality and Precision

Offset printing offers unparalleled quality, with the ability to produce crisp, high-resolution images. The consistency across prints is maintained due to the dedicated plate for each color.

Cost Efficiency

When printing in bulk, the overall cost per unit decreases, making offset printing highly cost-effective for large quantities. Business professionals understand the importance of maintaining budget-friendly operations without sacrificing quality.

Applications of Offset Printing

Offset printing is versatile. Its commonly used for producing magazines, books, brochures, newspapers, and more. This versatility highlights the strategic relevance of the technique across industries.

Commercial Printing

In the commercial landscape, where branding and marketing materials need to stand out, offset printing plays a pivotal role in ensuring high-quality and consistent output.

Custom Projects

From limited-edition art prints to personalized packaging, the adaptability of offset printing caters to a vast array of custom project requirements.

Technological Innovations in Offset Printing

Technological advancements have continually enhanced the efficiency and adaptability of offset printing. Integrating AI and IoT into printing systems has significantly optimized processes, predicting maintenance, and even reducing downtime.

Sustainability in Printing

Modern offset presses are designed to reduce waste and utilize eco-friendly inks, aligning with global sustainability goals.

Integration of Smart Technologies

Smart technology integration, like centralized device control, allows for streamlined operations and increased precision in print jobs.

Comparing Offset Printing with Digital Printing

While offset and digital printing share the common goal of delivering printed materials, they differ in setup, cost-effectiveness, and quality.

Offset vs Digital: Key Differences

Offset printing excels in large volume jobs due to its cost efficiency, whereas digital printing is preferable for shorter runs with varying data or images.

Making the Right Choice

Understanding these differences can help businesses make informed decisions on which printing method aligns best with their project needs and objectives.

The Future of Offset Printing

The future of offset printing is promising. As technology evolves, improvements in efficiency, quality, and environmental impact are anticipated. Professionals are continuously gearing up for future innovations.

Growing Trends

The integration of edge AI and machine learning models in printing offers new opportunities for enhanced precision and operational efficiency.

Green Printing Initiatives

Offset printing is seeing a significant shift toward environmentally-driven practices, such as the use of biodegradable materials and reduction of toxic chemicals.

FAQs about Offset Printing

What is the primary benefit of offset printing?

Offset printing delivers superior image quality, consistency, and is highly cost-effective for large print jobs.

Can offset printing be used for small print runs?

While it is possible, offset printing is best suited for larger print volumes due to the initial setup costs and plate preparation involved.

Is offset printing environmentally friendly?

Innovations in offset printing are increasingly focusing on sustainability, using eco-friendly inks and reducing paper waste to minimize environmental impact.

This article contains affiliate links. We may earn a commission at no extra cost to you.