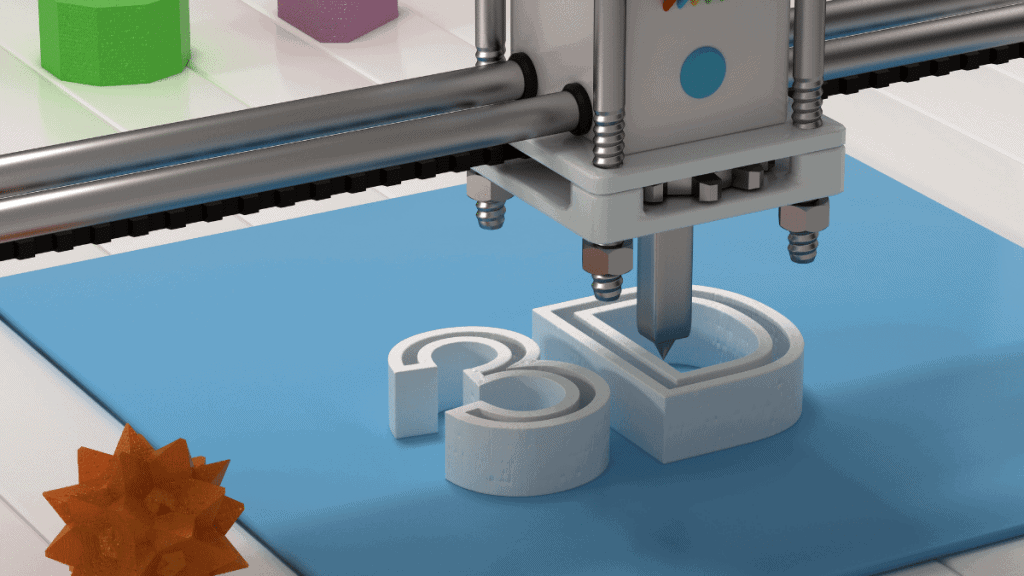

The world of manufacturing has undergone significant changes in recent years, with 3D printing emerging as one of the most transformative technologies. Also known as additive manufacturing, this process allows for the creation of three-dimensional objects by layering materials according to digital designs. The ability to produce complex shapes, prototypes, and even end-use products directly from a digital file is reshaping industries ranging from healthcare to automotive and aerospace.

Understanding what is 3D printing and its impact is crucial for anyone interested in technology, engineering, or modern production methods. This article explores the fundamentals of this innovative process, its various techniques, and the ways it is revolutionizing how products are designed and manufactured.

For those seeking further technical details, the U.S. Department of Energy provides an in-depth explanation of how 3D printers operate, including the science behind different printing methods and materials.

Understanding Additive Manufacturing

At its core, additive manufacturing refers to the process of building objects layer by layer from a digital model. Unlike traditional manufacturing, which often involves cutting away material from a solid block (subtractive manufacturing), 3D printing adds material only where it is needed. This approach leads to less waste, greater design flexibility, and the ability to create intricate geometries that would be difficult or impossible with conventional techniques.

The process starts with a computer-aided design (CAD) file, which is sliced into thin horizontal layers. The printer then follows these instructions, depositing or solidifying material—such as plastic, resin, or metal—one layer at a time until the final shape is achieved.

Key Technologies in 3D Printing

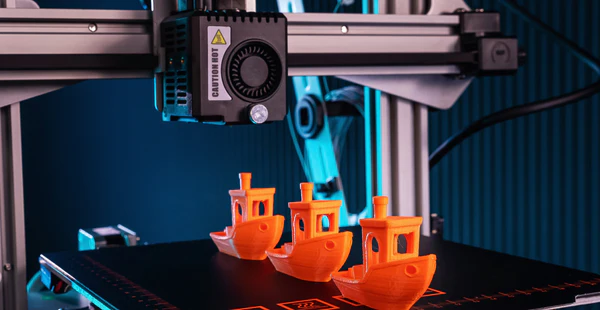

There are several main types of 3D printing technologies, each suited to different applications and materials. Here are some of the most common:

- Fused Deposition Modeling (FDM): This popular method uses thermoplastic filaments, which are heated and extruded through a nozzle to build objects layer by layer.

- Stereolithography (SLA): SLA printers use a laser to cure liquid resin into solid plastic, producing highly detailed parts with smooth surfaces.

- Selective Laser Sintering (SLS): SLS employs a laser to fuse powdered materials, such as nylon or metal, making it ideal for functional prototypes and end-use parts.

- Digital Light Processing (DLP): Similar to SLA, DLP uses a digital light projector to cure resin, allowing for fast and precise printing.

Each technique offers unique advantages in terms of speed, resolution, material compatibility, and cost, making it important to select the right method for a given project.

Applications Across Industries

The versatility of 3D printing has led to its adoption in a wide range of sectors. Some of the most notable applications include:

- Prototyping: Rapid prototyping allows designers and engineers to quickly create and test new ideas, reducing development time and costs.

- Healthcare: Customized implants, prosthetics, and even bioprinted tissues are now possible, improving patient outcomes and personalizing care.

- Aerospace and Automotive: Lightweight, complex components can be produced with greater efficiency, leading to improved performance and fuel savings.

- Consumer Goods: From eyewear to footwear, manufacturers can offer personalized products tailored to individual preferences.

- Construction: Large-scale printers are being used to build homes and infrastructure, often with sustainable materials and innovative designs.

As the technology matures, new uses continue to emerge, further expanding the impact of additive manufacturing.

Benefits and Challenges of Additive Manufacturing

The advantages of 3D printing are significant, but there are also challenges to consider. Some of the key benefits include:

- Design Freedom: Complex shapes and internal structures can be created without the constraints of traditional manufacturing.

- Customization: Products can be tailored to specific needs, from medical devices to consumer goods.

- Reduced Waste: Material is used efficiently, minimizing scrap and environmental impact.

- On-Demand Production: Parts can be produced as needed, reducing inventory and storage costs.

However, there are also limitations:

- Material Constraints: Not all materials are suitable for 3D printing, and some may lack the required strength or durability.

- Speed and Scale: While ideal for small batches and prototypes, large-scale production can be slower and more expensive than traditional methods.

- Post-Processing: Many parts require additional finishing steps, such as sanding or curing, to achieve the desired quality.

- Intellectual Property: The ease of copying digital files raises concerns about design protection and counterfeiting.

How Additive Manufacturing Is Transforming Production

The shift toward additive manufacturing is having a profound effect on the way products are conceived and produced. Some of the most notable transformations include:

- Decentralized Manufacturing: With the ability to print parts on-site or closer to the point of use, companies can reduce shipping times and costs.

- Supply Chain Resilience: On-demand production helps mitigate disruptions by enabling rapid response to changing demands or shortages.

- Innovation Acceleration: Faster prototyping and iteration cycles allow for more experimentation and quicker time-to-market for new products.

- Sustainability: Efficient material usage and the potential for recycling contribute to more environmentally friendly manufacturing practices.

These changes are not only making manufacturing more efficient but also opening up new possibilities for creativity, customization, and problem-solving across industries.

Frequently Asked Questions

What materials can be used in 3D printing?

A wide range of materials can be used, including various plastics (such as PLA, ABS, and nylon), resins, metals (like titanium and stainless steel), ceramics, and even composites. The choice of material depends on the printing technology and the desired properties of the finished object.

Is 3D printing suitable for mass production?

While additive manufacturing excels at prototyping and small-batch production, it is increasingly being used for mass production of specialized parts, especially in industries like aerospace and healthcare. However, for very large volumes, traditional manufacturing methods may still be more cost-effective.

How does 3D printing impact sustainability?

This technology can reduce waste by using only the material needed for each part, enable local production to cut down on transportation emissions, and support the use of recycled or biodegradable materials. However, energy consumption and material sourcing should also be considered when evaluating overall sustainability.