The world of 3D printing has expanded rapidly, offering a range of methods to turn digital designs into physical objects. Whether you’re a hobbyist, an engineer, or a business owner, understanding the types of 3D printing technologies is essential for choosing the right process for your needs. Each method has unique strengths, materials, and applications, making it important to compare them before investing in a printer or service.

In this guide, we’ll break down the most popular 3D printing processes, highlight their advantages and limitations, and help you decide which approach aligns best with your goals. If you’re new to this field, you might also find it helpful to read 3D printing technology explained for a broader overview of how these systems work.

Understanding Additive Manufacturing Methods

Additive manufacturing, commonly known as 3D printing, refers to a family of processes that build objects layer by layer from digital models. The main difference between these methods lies in the materials used and the way each layer is formed. Some techniques melt or fuse plastic filaments, while others cure liquid resins or sinter powdered metals.

For a step-by-step breakdown of how these processes work, check out this how 3D printing works guide. Now, let’s explore the most common categories of 3D printing and what sets them apart.

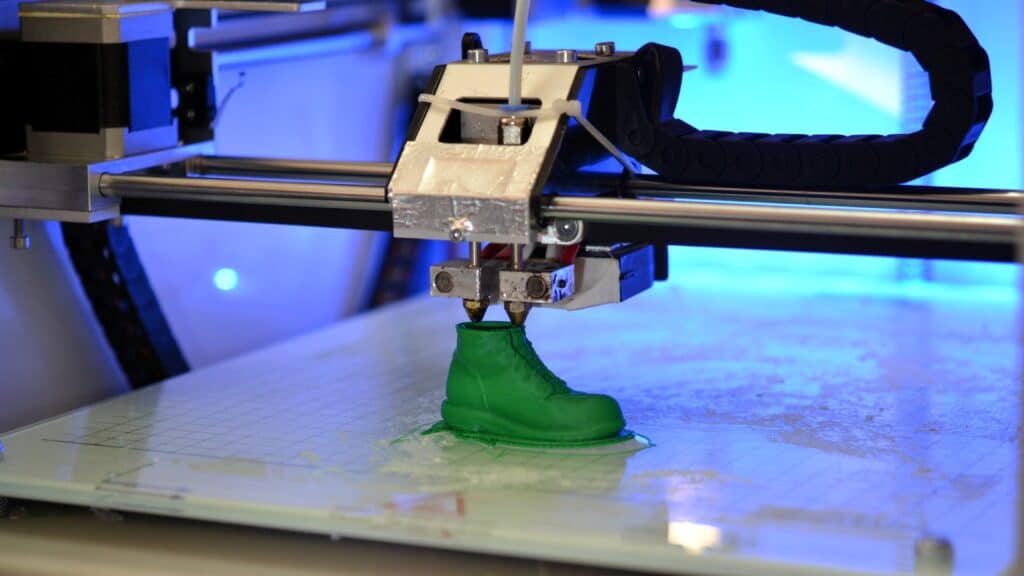

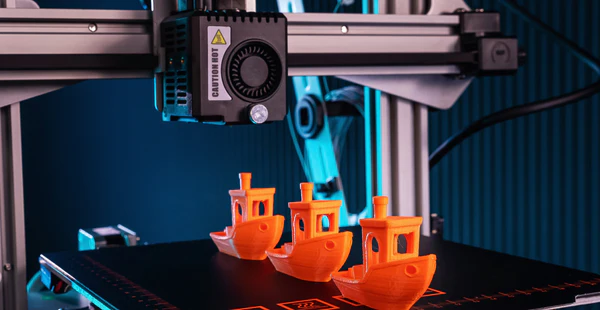

Fused Deposition Modeling (FDM): The Most Accessible Option

Fused Deposition Modeling, also known as Fused Filament Fabrication (FFF), is the most widely used and accessible 3D printing technology. FDM printers work by heating and extruding thermoplastic filament through a nozzle, which moves in precise patterns to build up each layer.

Key Features of FDM Printing

- Materials: PLA, ABS, PETG, TPU, and other thermoplastics

- Cost: Generally the most affordable printers and materials

- Applications: Prototyping, hobby models, functional parts, educational projects

- Strengths: Easy to use, wide material selection, low entry cost

- Limitations: Visible layer lines, lower resolution than resin or powder-based methods

FDM is ideal for beginners, makers, and anyone looking for a cost-effective way to produce sturdy plastic parts. If you want to learn more about the basics and applications of additive manufacturing, see this introduction to additive manufacturing.

Resin-Based Printing: SLA, DLP, and LCD Technologies

Resin printing uses liquid photopolymers that are cured layer by layer using light. The three main types are Stereolithography (SLA), Digital Light Processing (DLP), and LCD-based Masked Stereolithography (MSLA). These methods are known for their high resolution and ability to produce intricate details.

Advantages and Drawbacks of Resin Printing

- Materials: UV-curable resins with various properties (standard, tough, flexible, dental, castable)

- Cost: Resin printers are affordable, but resins can be pricier than FDM filaments

- Applications: Miniatures, jewelry, dental models, prototypes requiring fine details

- Strengths: Exceptional detail, smooth surfaces, ideal for small intricate parts

- Limitations: Post-processing required (washing and curing), resins can be messy and require safety precautions

If your projects demand high precision or you’re interested in producing small, highly detailed models, resin-based printers are a strong choice.

Powder Bed Fusion: SLS and Beyond

Powder Bed Fusion (PBF) encompasses several advanced types of 3D printing technologies, including Selective Laser Sintering (SLS) for plastics and Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS) for metals. These methods use a laser or electron beam to fuse powdered material layer by layer.

What Sets Powder-Based Printing Apart?

- Materials: Nylon, polyamide, TPU, metals (aluminum, titanium, steel)

- Cost: Higher equipment and material costs; mainly used in industrial settings

- Applications: Functional prototypes, end-use parts, aerospace, automotive, medical devices

- Strengths: No support structures needed, strong and complex geometries possible

- Limitations: Expensive, requires specialized equipment and post-processing

Powder Bed Fusion is best suited for professional and industrial applications where part strength, durability, and complex shapes are critical.

Other Notable 3D Printing Methods

While FDM, resin, and powder-based processes are the most common, several other additive manufacturing techniques are worth mentioning:

- Binder Jetting: Uses a liquid binder to fuse powder particles. Suitable for full-color models and metal parts.

- Material Jetting: Deposits droplets of material, similar to inkjet printing, for multi-material and multi-color parts.

- Sheet Lamination: Bonds sheets of material (paper, plastic, metal) layer by layer.

- Directed Energy Deposition (DED): Melts material as it is deposited, used for large-scale metal parts and repairs.

For a deeper dive into the mechanisms behind these techniques, you can visit this comprehensive explanation of 3D printing mechanisms and examples.

How to Choose the Best 3D Printing Technology for Your Needs

Selecting the right process depends on your project requirements, budget, and desired results. Here are some factors to consider when comparing types of 3D printing technologies:

- Detail and Resolution: Resin printers (SLA, DLP, LCD) excel at fine details, while FDM is better for larger, less intricate parts.

- Material Properties: Consider strength, flexibility, heat resistance, and biocompatibility.

- Cost: FDM is the most budget-friendly, resin printing is moderately priced, and powder bed fusion is typically reserved for industrial use.

- Ease of Use: FDM is beginner-friendly; resin and powder-based methods require more post-processing and safety precautions.

- Application: Match the technology to your end goal—prototyping, functional parts, art, or manufacturing.

If you’re curious about how 3D printing is transforming industries, read more about what is 3D printing and its impact on modern manufacturing.

Frequently Asked Questions

What is the difference between FDM and resin 3D printers?

FDM printers use heated plastic filament to build objects layer by layer, making them affordable and easy to use. Resin printers, such as SLA or DLP, cure liquid resin with light for higher detail and smoother surfaces, but they require more post-processing and safety measures.

Which 3D printing technology is best for beginners?

FDM is generally the best starting point for newcomers due to its low cost, wide material availability, and straightforward operation. Many entry-level models are available, and the learning curve is manageable for most users.

Can I print metal parts with consumer 3D printers?

Printing metal parts typically requires advanced technologies like SLS or DMLS, which are expensive and used mainly in industrial environments. Some desktop machines offer metal-infused filaments, but these do not produce fully metallic parts.

How do I decide which 3D printing process to use?

Consider your project’s requirements: the level of detail needed, material properties, budget, and intended application. For prototypes and functional plastic parts, FDM is a solid choice. For high-detail models or miniatures, resin printing is preferable. For industrial-grade strength or metal parts, powder bed fusion is recommended.