The aviation industry is a cornerstone of global transportation, demanding the highest levels of safety and reliability. One of the critical challenges faced by this sector is the threat of counterfeiting, which can compromise both safety and trust. Security printing in aviation parts is a vital solution that addresses these concerns by ensuring the authenticity and integrity of aviation components.

Understanding Security Printing

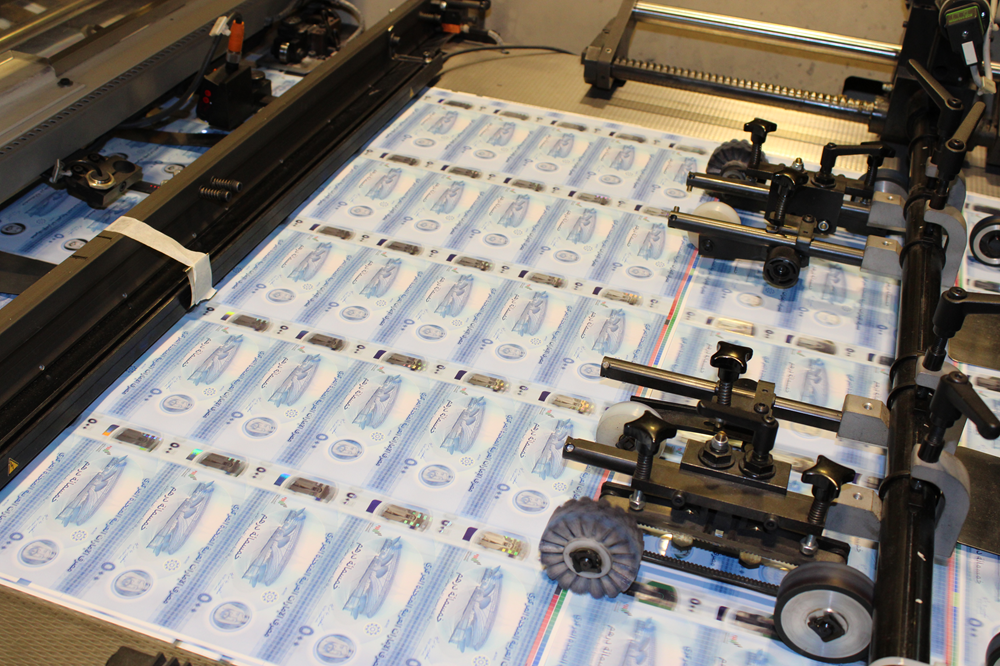

Security printing involves the use of advanced printing techniques to create identifiable, tamper-proof, and counterfeit-resistant features. These techniques are crucial in safeguarding aviation parts, ensuring that every component is genuine and meets the rigorous standards required for air travel.

Importance of Security Printing in Aviation

With the increasing sophistication of counterfeiters, the aviation industry must adopt robust measures to protect its parts. Security printing serves as a frontline defense, offering a way to verify authenticity and prevent the circulation of fake components. The implications of not using such measures can be severe, leading to safety risks and financial losses.

Techniques Used in Security Printing

Various techniques are employed in security printing, each offering unique benefits. These include holograms, watermarks, color-shifting inks, and microprinting. Each technique enhances the security level of aviation parts, making it extremely difficult for counterfeiters to reproduce.

Holograms in Aviation Parts

Holograms are one of the most effective security features used in aviation. They provide a visual and tactile method to verify authenticity, as they are difficult to replicate without specialized equipment.

Watermarks and Their Role

Watermarks are another essential security feature. They are embedded into materials during manufacturing, providing a hidden yet verifiable mark that is hard to forge.

Color-Shifting Inks

Color-shifting inks change appearance when viewed from different angles. This feature is commonly used in currency and is now being adapted for aviation parts to enhance security.

Microprinting: Adding an Extra Layer of Security

Microprinting involves the use of extremely small text that is difficult to reproduce accurately without advanced technology. This feature is often used in conjunction with other security measures to provide multiple layers of protection.

Benefits of Implementing Security Printing

The benefits of security printing in aviation parts extend beyond just preventing counterfeiting. They include enhancing brand reputation, improving safety standards, and ensuring regulatory compliance.

Enhancing Brand Reputation

By using security printing, manufacturers demonstrate their commitment to quality and safety, enhancing their reputation in the industry.

Improving Safety Standards

Ensuring that every part is genuine and safe is critical. Security printing helps maintain high safety standards by preventing the infiltration of counterfeit parts.

Ensuring Regulatory Compliance

Compliance with international aviation regulations is essential. Security printing aids in meeting these standards by providing verifiable evidence of part authenticity.

Challenges in Implementing Security Printing

Despite its benefits, implementing security printing comes with challenges, including cost, technological barriers, and the need for continuous innovation to stay ahead of counterfeiters.

Cost Implications

The initial investment for implementing security printing can be high. However, the long-term benefits often outweigh these costs, especially when considering the potential losses from counterfeit parts.

Technological Barriers

Advanced technology is required for effective security printing. Companies must invest in both equipment and skilled personnel to successfully implement these measures.

Need for Continuous Innovation

Counterfeiters are constantly evolving their techniques. Continuous innovation in security printing is necessary to stay one step ahead and ensure ongoing protection.

Future of Security Printing in Aviation

The future of security printing in aviation parts looks promising, with advancements in technology leading to even more sophisticated security measures. The integration of digital solutions and the Internet of Things (IoT) are expected to play significant roles in enhancing the security of aviation components.

Digital Solutions

Digital solutions, such as blockchain and digital watermarks, offer new ways to secure aviation parts. These technologies provide additional layers of verification and traceability.

Role of IoT

The IoT can enhance security by enabling real-time monitoring of parts throughout their lifecycle. This technology allows for instant verification and tracking, ensuring that any anomalies are quickly identified and addressed.

Conclusion

In conclusion, security printing in aviation parts is an essential strategy for ensuring the safety and authenticity of components. As the industry continues to evolve, the adoption of advanced security measures will become increasingly important. Embracing these technologies not only protects against counterfeiting but also enhances overall safety and compliance within the aviation sector.

Frequently Asked Questions (FAQ)

What is security printing in aviation?

Security printing in aviation involves using advanced printing techniques to prevent counterfeiting and ensure the authenticity of aviation parts.

Why is security printing important in aviation?

It is crucial because it protects against the infiltration of counterfeit parts, ensuring safety, compliance, and maintaining industry trust.

What are some common security printing techniques?

Common techniques include holograms, watermarks, color-shifting inks, and microprinting, each offering unique security benefits.

This article contains affiliate links. We may earn a commission at no extra cost to you.