Robotic 3D printing systems are rapidly transforming the landscape of modern manufacturing. By integrating advanced robotics with additive manufacturing, these solutions enable the production of complex, large-scale, and customized components across a wide range of industries. As businesses seek greater efficiency, flexibility, and innovation, robotic automation in 3D printing is becoming a key driver of industrial progress.

This article explores how automated 3D printing platforms are reshaping industrial workflows, the major advantages they offer, and the sectors leading the adoption of this technology. For those interested in the technical side of design, you may also want to review printing complex geometries for insights on producing intricate parts with additive manufacturing.

Understanding Automated 3D Printing Platforms

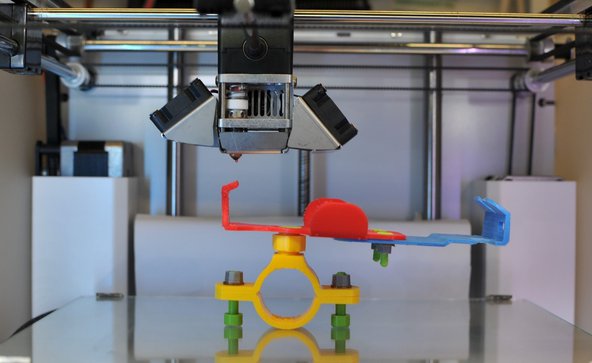

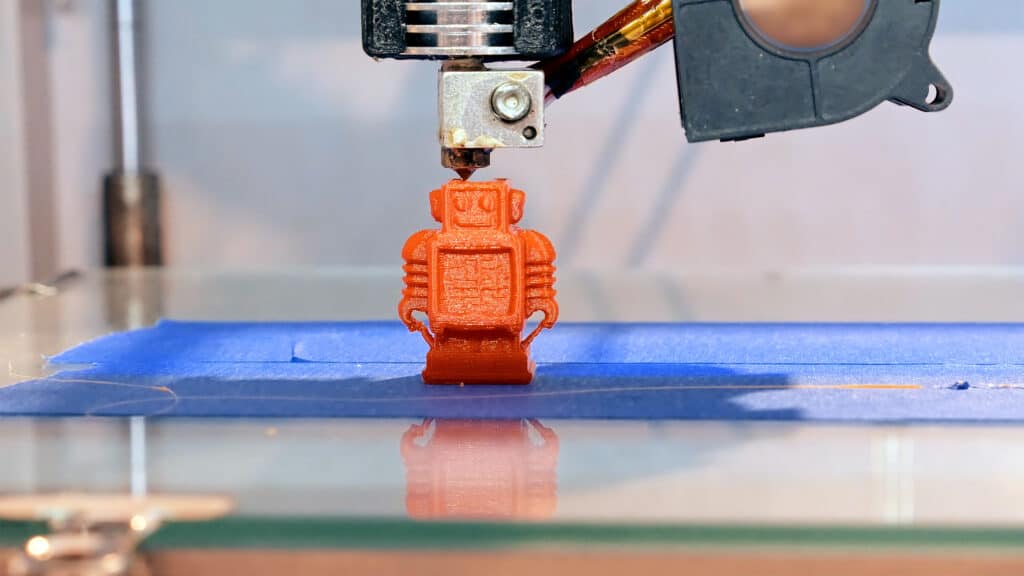

At their core, robotic 3D printing systems combine the precision and repeatability of industrial robots with the flexibility of additive manufacturing. Unlike traditional 3D printers that operate on fixed axes, these systems use robotic arms or gantries to manipulate print heads, allowing for multi-directional movement and the creation of parts with complex geometries.

This approach enables manufacturers to build larger components, utilize a broader range of materials, and automate post-processing steps. The integration of robotics also supports continuous operation, reducing downtime and manual intervention.

Key Industrial Applications of Robotic 3D Printing

The adoption of automated additive manufacturing is accelerating across several sectors. Below are some of the most impactful use cases:

- Aerospace: Aircraft manufacturers leverage robotic 3D printing to produce lightweight structural parts, engine components, and custom tooling. The ability to print large, strong, and lightweight parts helps reduce fuel consumption and improve performance.

- Automotive: Car makers use these systems for rapid prototyping, end-use parts, and the creation of custom fixtures. The flexibility of robotic arms allows for the fabrication of complex shapes that would be challenging with conventional methods.

- Construction: Large-scale 3D printing robots are now building architectural elements, walls, and even entire homes. This approach can significantly cut construction time and material waste.

- Healthcare: Hospitals and medical device companies utilize robotic 3D printing for patient-specific implants, prosthetics, and surgical guides, improving outcomes and reducing lead times.

- Tooling and Manufacturing: Factories deploy these systems to create jigs, fixtures, and molds on demand, streamlining production and enabling rapid adaptation to new product lines.

Advantages of Robotic Additive Manufacturing

The shift toward robotic automation in 3D printing brings several significant benefits to industrial users:

- Scalability: Robotic arms can build much larger parts than traditional desktop or gantry-based printers, making them suitable for aerospace, automotive, and construction projects.

- Design Freedom: With multi-axis movement, these systems can fabricate intricate geometries, overhangs, and internal structures that are difficult or impossible with conventional subtractive processes.

- Material Versatility: Robotic 3D printing can handle a wide range of materials, from thermoplastics and composites to metals and concrete, broadening the scope of possible applications.

- Reduced Labor Costs: Automation minimizes the need for manual supervision, allowing for continuous, unattended operation and freeing up skilled workers for higher-value tasks.

- Faster Prototyping and Production: The ability to quickly iterate designs and produce functional parts accelerates product development cycles and shortens time-to-market.

- Waste Reduction: Additive manufacturing inherently uses only the material required for the part, and robotic systems further optimize deposition paths, reducing scrap and environmental impact.

How Robotic 3D Printing Systems Work

These advanced platforms typically consist of a robotic arm equipped with a specialized print head, a material feed system, and sophisticated software for path planning and process control. The workflow involves several key steps:

- Design Preparation: Engineers create a digital model using CAD software. For best results, understanding how to design for 3D printing is essential.

- Path Generation: The software slices the model and generates toolpaths optimized for the robot’s kinematics, ensuring precise deposition from multiple angles.

- Material Deposition: The robotic arm moves the print head along the programmed paths, extruding or depositing material layer by layer to build the part.

- Post-Processing: Some systems automate finishing steps such as support removal, surface smoothing, or even multi-material assembly.

The flexibility of robotic arms allows these systems to print on non-planar surfaces, combine additive and subtractive processes, and even operate in challenging environments.

Challenges and Considerations in Industrial 3D Printing Automation

While the advantages are substantial, deploying robotic additive manufacturing solutions requires careful planning. Some common challenges include:

- Initial Investment: The cost of industrial robots, large-scale printers, and integration can be significant, though long-term savings often offset these expenses.

- Technical Expertise: Operating and maintaining these systems demands specialized knowledge in robotics, software, and materials science.

- Quality Control: Ensuring consistent part quality at scale requires robust monitoring and process validation.

- File Preparation: Understanding 3D printing file formats explained is vital for smooth workflow and compatibility.

- Material Handling: Some advanced materials may require controlled environments or special handling procedures.

Despite these hurdles, ongoing advances in software, sensor integration, and material science are making robotic 3D printing more accessible and reliable for a growing range of businesses.

Future Trends in Automated Additive Manufacturing

The evolution of robotic 3D printing is closely linked to broader trends in Industry 4.0 and smart manufacturing. Some key developments to watch include:

- AI-Driven Optimization: Artificial intelligence is being used to optimize print paths, predict failures, and adapt processes in real time.

- Multi-Material Printing: New systems are enabling the simultaneous deposition of different materials, expanding the range of functional parts that can be produced.

- Integration with Digital Twins: Linking robotic printers with digital models of factory operations allows for seamless simulation, monitoring, and optimization.

- On-Demand Manufacturing: As supply chains become more flexible, robotic 3D printing is enabling localized, just-in-time production for spare parts and custom products.

For a deeper understanding of design best practices, see 3D modeling tips for printing and CAD for 3D printing beginners.

Frequently Asked Questions

What industries benefit most from robotic 3D printing?

Sectors such as aerospace, automotive, construction, and healthcare are at the forefront of adopting automated additive manufacturing. These industries require complex, customized, or large-scale parts that benefit from the flexibility and scalability of robotic systems.

How does robotic 3D printing differ from traditional 3D printing?

While conventional 3D printers operate on fixed axes, robotic platforms use multi-axis arms for greater movement and flexibility. This enables the production of larger, more intricate parts and allows for printing on non-planar surfaces.

What materials can be used with robotic additive manufacturing?

These systems can process a wide variety of materials, including plastics, composites, metals, and even concrete. The choice of material depends on the application and the capabilities of the specific system.

Where can I learn more about 3D printing technology?

For a comprehensive introduction, visit this guide to 3D printing fundamentals which covers the basics, technologies, and applications of additive manufacturing.