Resin 3D printing basics are essential knowledge for anyone interested in producing highly detailed models, prototypes, or functional parts. This technology, also known as stereolithography (SLA) or digital light processing (DLP), uses liquid resin and light to create objects with remarkable precision. Whether you’re a hobbyist, designer, or professional, understanding the core techniques and safety considerations can help you get the most out of your 3D printer while protecting your health and workspace.

In this article, we’ll cover the fundamental processes, compare resin printing with other methods, and provide practical safety tips for handling materials and equipment. If you’re curious about how this technology fits into the broader landscape of additive manufacturing, the history of 3D printing offers valuable context on its evolution and impact.

Understanding the Fundamentals of Resin-Based 3D Printing

At its core, resin 3D printing basics involve using a photosensitive liquid resin that solidifies when exposed to a specific wavelength of light. The most common technologies in this category are SLA and DLP. Both methods create objects layer by layer, but they differ in how the light source is applied:

- SLA (Stereolithography): Uses a laser to trace and cure each layer of the object’s cross-section.

- DLP (Digital Light Processing): Projects an entire image of a layer at once using a digital projector, curing the resin more quickly.

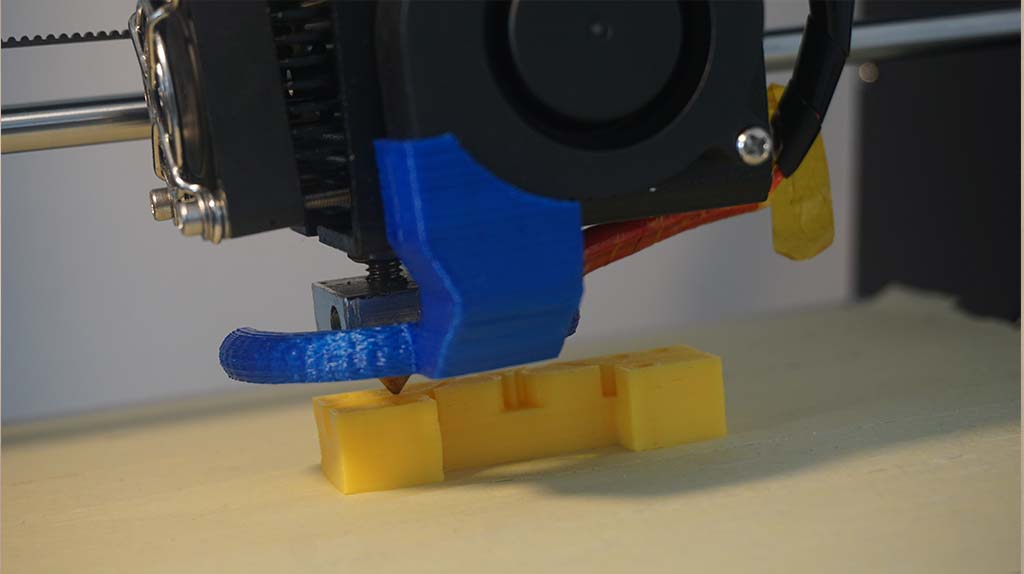

These processes allow for extremely fine details and smooth surface finishes, making them ideal for miniatures, dental models, jewelry, and engineering prototypes. Compared to filament-based printers (FDM), resin machines offer higher resolution but require more post-processing and careful handling.

Key Techniques for Successful Resin Printing

Mastering the essential techniques is crucial for achieving consistent, high-quality results. Here are some important steps and tips to keep in mind:

1. Preparing the 3D Model

Before printing, models must be properly oriented and supported. Resin printers require the addition of support structures to prevent parts from collapsing or detaching during the build process. Most slicing software provides automatic support generation, but manual adjustments often yield better outcomes.

2. Printer Calibration and Settings

Accurate calibration is vital. This includes leveling the build platform and ensuring the correct exposure times for your specific resin. Each brand and color of resin may require slightly different settings, so always consult the manufacturer’s guidelines and perform test prints when using new materials.

3. Post-Processing and Cleaning

Once printing is complete, the object must be removed from the build platform and cleaned to remove uncured resin. This typically involves rinsing the part in isopropyl alcohol (IPA) or a specialized cleaning solution. After cleaning, the model is cured under UV light to achieve full strength and stability.

4. Troubleshooting Common Issues

Problems like layer separation, failed supports, or incomplete curing are common for beginners. Regular maintenance, such as cleaning the resin vat and checking the FEP film for damage, can prevent many issues. If you encounter persistent problems, reviewing your slicing settings and ensuring the workspace is dust-free can help.

Safety Tips for Resin Printing at Home or Work

While resin printing offers outstanding detail, it also introduces unique safety considerations. Liquid resins can be hazardous if not handled properly. Here are some best practices to keep your workspace safe:

- Wear Personal Protective Equipment (PPE): Always use nitrile gloves and safety goggles when handling liquid resin or cleaning printed parts.

- Ensure Proper Ventilation: Operate your printer in a well-ventilated area or use an enclosure with an air filter to minimize exposure to fumes.

- Store Materials Safely: Keep resins in their original containers, tightly sealed, and away from direct sunlight or heat sources.

- Dispose of Waste Responsibly: Uncured resin and contaminated cleaning solutions should be disposed of according to local hazardous waste regulations.

- Clean Spills Immediately: Use paper towels and IPA to clean up any resin spills, and avoid skin contact.

Following these guidelines will help you enjoy the benefits of resin printing while minimizing health risks.

Comparing Resin Printing to Other 3D Technologies

Resin-based printers stand out for their ability to produce highly detailed models, but how do they compare to other methods like FDM? While FDM printers use melted plastic filament and are generally easier to use and maintain, resin machines excel in applications where surface finish and precision are critical.

For a deeper dive into the types of 3D printing technologies available, including their strengths and weaknesses, exploring comparative guides can help you choose the right tool for your needs. Additionally, understanding the benefits of 3D printing across different methods can inform your decision-making process.

If you’re weighing the options between filament and resin systems, the FDM vs SLA printing comparison explains the key differences, pros, and cons of each approach.

Applications and Future Trends in Resin Printing

The applications for resin-based additive manufacturing continue to expand. Industries such as dentistry, jewelry, prototyping, and even small-scale manufacturing rely on this technology for its accuracy and versatility. As new resins are developed with improved mechanical properties and biocompatibility, the range of possible uses will only grow.

Looking ahead, advancements in printer design and material science are expected to make resin printing faster, more affordable, and even safer. For insights into where the industry is headed, the future of 3D printing highlights emerging trends and innovations shaping the next generation of manufacturing.

For a broader understanding of how additive manufacturing is transforming industries, you can also explore the definition and overview of 3D printing provided by industry experts.

Frequently Asked Questions

What are the main advantages of resin 3D printing over FDM?

Resin-based systems offer much higher resolution and smoother surface finishes compared to FDM printers. They are ideal for applications that require fine details, such as miniatures, dental models, and jewelry. However, they require more post-processing and careful handling of materials.

Is resin 3D printing safe for home use?

Yes, but only with proper precautions. Always use gloves and goggles, ensure good ventilation, and follow manufacturer instructions for handling and disposal. Never allow children or pets near uncured resin or operating printers.

How do I clean and cure resin prints?

After printing, rinse the model in isopropyl alcohol or a recommended cleaning solution to remove uncured resin. Once clean, cure the model under UV light (using a dedicated curing station or sunlight) to achieve full strength and stability.

Can I use any resin with my printer?

Not all resins are compatible with every printer. Always check your printer’s specifications and use resins recommended by the manufacturer for best results.

What should I do if I spill resin?

Clean spills immediately using paper towels and isopropyl alcohol, and dispose of waste according to local hazardous material guidelines. Avoid skin contact and ventilate the area thoroughly.