The powder bed fusion process has become a cornerstone in the world of additive manufacturing. This advanced 3D printing technique enables the creation of complex, high-strength parts by fusing layers of powdered material with a heat source. Its precision and versatility have made it popular across industries ranging from aerospace to healthcare. Understanding how this technology works and where it excels is essential for anyone interested in modern manufacturing or rapid prototyping.

In this guide, we’ll break down the essential steps involved in powder bed fusion, explore the different technologies under its umbrella, and highlight the most impactful applications. For those looking to enhance their finished prints, our resource on sanding and finishing 3D prints offers practical post-processing tips.

Understanding Powder Bed Fusion Technology

At its core, powder bed fusion (PBF) refers to a family of additive manufacturing processes where a heat source—typically a laser or electron beam—selectively fuses regions of a powder bed to build up a part layer by layer. The process is highly controlled, allowing for the production of intricate geometries and strong, functional components.

Several methods fall under the PBF umbrella, including:

- Selective Laser Sintering (SLS): Uses a laser to sinter polymer powders, commonly nylon or polyamide.

- Selective Laser Melting (SLM): Utilizes a laser to fully melt metal powders, resulting in dense, high-strength metal parts.

- Electron Beam Melting (EBM): Employs an electron beam to melt metal powders, often used for titanium alloys in medical and aerospace applications.

- Direct Metal Laser Sintering (DMLS): Similar to SLM, but with subtle differences in melting and sintering mechanisms.

Each technique is chosen based on material requirements, part complexity, and desired mechanical properties.

Key Steps in the Powder Bed Fusion Workflow

The powder bed fusion process follows a systematic workflow to ensure accuracy and repeatability. Here’s a closer look at the main stages:

1. Preparing the Digital Model

The journey begins with a 3D CAD model, which is sliced into thin layers using specialized software. This digital preparation defines the geometry and guides the machine throughout the build.

2. Loading the Powder Material

A fine layer of powder—metal, polymer, or ceramic—is spread evenly across the build platform. The quality and consistency of the powder are crucial for achieving optimal results.

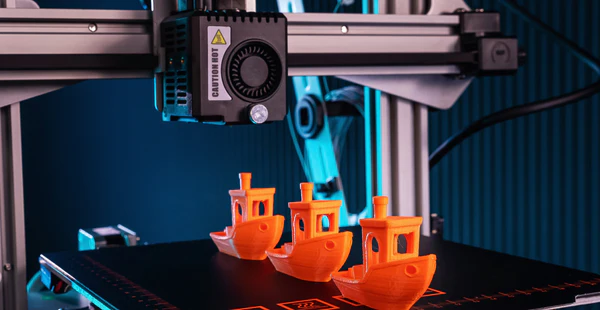

3. Selective Fusion of Powder Layers

The machine’s laser or electron beam traces the cross-section of the part, fusing or melting the powder in targeted areas. Unfused powder remains loose, supporting the structure as each layer is built.

4. Recoating and Repeating

After each layer is fused, a new layer of powder is spread, and the process repeats. This cycle continues until the entire object is complete.

5. Cooling and Powder Removal

Once printing is finished, the build chamber cools to prevent thermal stress. The part is then removed from the powder bed, and excess powder is brushed or blasted away. This leftover powder can often be recycled for future builds.

6. Post-Processing

Depending on the application, parts may undergo additional steps such as heat treatment, machining, or surface finishing. For tips on achieving a smooth finish, see our article on post processing 3D prints.

Materials Used in Powder Bed Fusion

The choice of powder material significantly impacts the properties of the final part. Common options include:

- Metals: Stainless steel, titanium, aluminum, cobalt-chrome, and nickel alloys are widely used for their strength and durability.

- Polymers: Nylon (PA12), polyamide, and TPU are popular for lightweight, flexible, or functional prototypes.

- Ceramics: Alumina and zirconia are used for specialized applications requiring high temperature or wear resistance.

Each material brings unique benefits, making powder bed fusion adaptable to a broad range of industries.

Applications Across Industries

The flexibility and precision of powder bed fusion have led to its adoption in numerous fields:

- Aerospace: Lightweight, high-strength components such as brackets, housings, and turbine blades are produced with intricate internal structures that would be impossible to machine conventionally.

- Medical: Custom implants, prosthetics, and surgical tools benefit from precise, patient-specific designs and biocompatible materials.

- Automotive: Functional prototypes, lightweight parts, and even end-use components are created for performance vehicles and electric cars.

- Industrial Manufacturing: Tooling, jigs, and fixtures can be rapidly produced and easily customized.

- Consumer Products: Wearables, eyewear, and even art pieces leverage the design freedom and material options of PBF.

As the technology matures, new applications continue to emerge, driven by the ability to produce complex parts with minimal waste.

Advantages and Limitations

The powder bed fusion process offers several compelling advantages:

- Enables highly complex geometries and internal features

- Delivers excellent mechanical properties and material density

- Reduces material waste compared to subtractive manufacturing

- Allows for rapid prototyping and on-demand production

However, there are also some limitations to consider:

- Equipment and materials can be expensive

- Build volumes are typically smaller than traditional manufacturing

- Surface finish may require post-processing for smoothness

- Process parameters must be tightly controlled to avoid defects

For those interested in improving the surface quality of their prints, our guide on painting 3D printed models provides helpful finishing techniques.

Getting Started with Powder Bed Fusion

Adopting this advanced manufacturing method requires careful planning. Here are a few steps to help you begin:

- Assess your application’s requirements for material, strength, and complexity.

- Choose the appropriate PBF technology (SLS, SLM, EBM, or DMLS) based on your needs.

- Prepare your digital models with attention to design for additive manufacturing (DfAM) principles.

- Partner with a reputable service provider or invest in a suitable 3D printer.

- Consider post-processing options to achieve the desired finish and performance.

For a deeper dive into available 3D printing solutions, explore Autodesk’s 3D printing resources for insights on software, hardware, and workflow optimization.

Frequently Asked Questions

What is the difference between SLS and SLM?

SLS (Selective Laser Sintering) uses a laser to sinter polymer powders, while SLM (Selective Laser Melting) fully melts metal powders to produce dense metal parts. Both are forms of powder bed fusion but are optimized for different materials and applications.

Can powder bed fusion be used for mass production?

While traditionally used for prototyping and low-volume production, advancements in machine speed and automation are making powder bed fusion increasingly viable for small to medium batch manufacturing, especially for complex or customized parts.

How do you improve the surface finish of PBF parts?

Surface finish can be enhanced through post-processing methods such as sanding, tumbling, bead blasting, or painting. For detailed techniques, see our article on how to prevent warping in prints and related finishing tips.

What are the main safety considerations?

Handling fine powders requires proper ventilation and personal protective equipment to avoid inhalation or skin contact. Machines should be operated according to manufacturer guidelines to ensure safe use of lasers or electron beams.

Conclusion

The powder bed fusion process stands out as a transformative technology in additive manufacturing, enabling the creation of parts that were once impossible to produce. By understanding its key steps, material options, and diverse applications, manufacturers and designers can unlock new possibilities for innovation and efficiency. As the field evolves, staying informed about best practices and emerging trends will be essential for leveraging the full potential of this advanced production method.