In the ever-evolving world of printing technology, two terms often emerge in discussions: Offset printing vs lithographic printing. These methods have revolutionized the printing industry, offering unique advantages that cater to various needs. Whether you’re printing business cards, magazines, or stationery, understanding these techniques is crucial for making informed decisions.

What is Offset Printing?

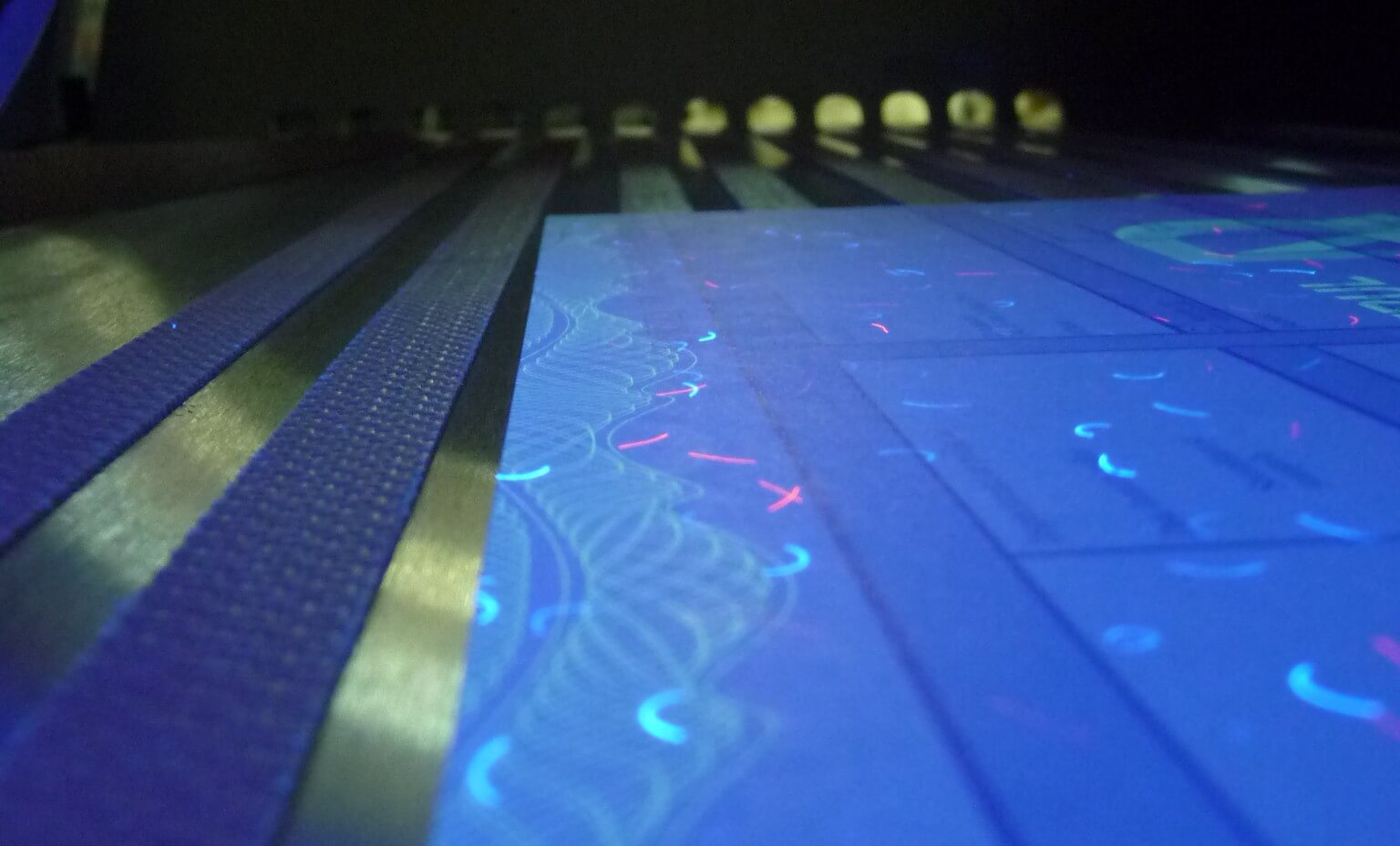

Offset printing, also known as offset lithography, is a popular printing method that involves transferring an inked image from a plate to a rubber blanket and then to the printing surface. It’s widely used for producing high-quality prints in large volumes, making it ideal for commercial printing projects, such as magazines and business cards.

Understanding Lithographic Printing

Lithographic printing, often simply referred to as lithography, is a method based on the immiscibility of oil and water. This technique is used to print artwork or text on paper or other materials. It is known for its ability to produce high-quality images and is often used in fine art printing and publishing.

The Key Differences: Offset vs Lithographic Printing

While both methods share some similarities, they differ in terms of applications, costs, and processes. Offset printing is typically more cost-effective for high-volume jobs, while lithographic printing is often chosen for its superior image quality and detail, particularly in artistic applications.

Applications and Suitability

Offset printing is highly versatile and used for a wide range of products, including newsletters and stationery. In contrast, lithographic printing excels in applications where image quality is paramount, such as high-end art books or gallery prints.

Cost and Efficiency

For large print runs, offset printing is generally more cost-effective, as the setup costs are offset by the economies of scale. In contrast, lithographic printing can be more expensive due to the intricate setup and materials required, but it offers unparalleled quality for specific projects.

Quality and Detail

Lithographic printing is renowned for its ability to reproduce fine details and subtle gradations of color, making it a preferred choice for artists and photographers. Offset printing, while slightly less detailed, still offers excellent quality and is suitable for most commercial needs.

Choosing the Right Printing Method

When deciding between offset printing vs lithographic printing, consider the specific needs of your project. For high-volume, commercial printing, offset is typically the way to go. However, if your project demands exceptionally high detail and quality, lithography might be worth the investment.

Environmental Considerations

Both printing methods have environmental impacts, but advancements in technology have made them more eco-friendly. Offset printing often uses soy-based inks and recycled paper, while lithographic printing has seen improvements in reducing chemical use and waste.

Technological Advancements in Printing

Both offset and lithographic printing have benefited from technological advancements. Modern presses are more efficient, producing less waste and using fewer resources. This evolution has made both methods more accessible and sustainable.

The Future of Printing

As technology continues to advance, the line between printing methods is blurring. Innovations in ink and paper technology, along with digital integration, are paving the way for future developments that could blend the best aspects of both offset and lithographic printing.

FAQs about Offset and Lithographic Printing

1. What is the main advantage of offset printing?

Offset printing is primarily advantageous for high-volume printing jobs due to its cost-effectiveness and efficiency.

2. Why choose lithographic printing?

Lithographic printing is chosen for its superior image quality and ability to reproduce fine details, making it ideal for artistic projects.

3. Are both methods eco-friendly?

Both methods have become more eco-friendly due to technological advancements, though the environmental impact can vary depending on the materials and processes used.

For more insights on printing methods, you can explore this external resource.

This article contains affiliate links. We may earn a commission at no extra cost to you.