In the ever-evolving world of print technology, businesses often find themselves at a crossroads, choosing between two prevalent methods: Offset printing vs flexographic printing. Both techniques have unique advantages and cater to different business needs. Understanding these differences is crucial for making informed decisions that align with your company’s goals.

Understanding Offset Printing

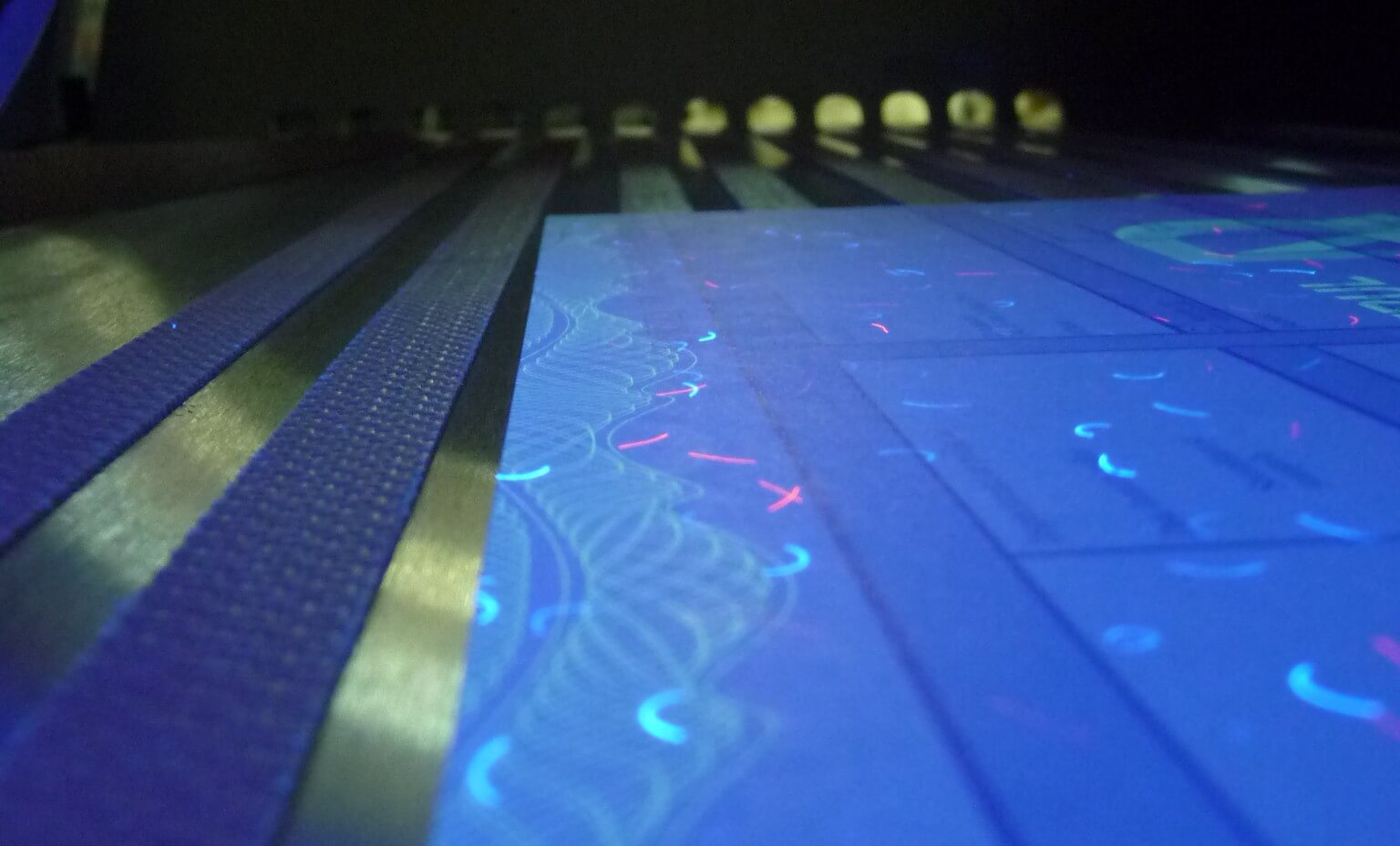

Offset printing is a traditional printing method that involves transferring an inked image from a plate to a rubber blanket and then onto the printing surface. This method is popular for producing high-quality and consistent print outputs, especially for large-scale productions. It is commonly used for printing books, magazines, brochures, and more. For more in-depth information, you can visit this detailed guide on offset printing.

How Does Offset Printing Work?

The process begins with creating a metal plate that contains the image of the content to be printed. The plate is then inked, and the image is transferred to a rubber blanket. The final step involves pressing the rubber blanket onto paper or other materials, resulting in a high-quality print. This technique ensures precision and color fidelity, making it ideal for projects requiring detailed and vibrant images.

Exploring Flexographic Printing

Flexographic printing, on the other hand, is a versatile and efficient printing process primarily used for packaging and labels. It employs flexible relief plates that can print on a wide range of substrates, including plastics, metallic films, and paper. Known for its speed and cost-effectiveness, flexographic printing is ideal for large-volume orders.

Advantages of Flexographic Printing

One of the significant benefits of flexographic printing is its ability to print on various materials with ease. Additionally, it offers quick drying times due to the use of fast-drying inks, which is beneficial for high-speed production. This method is also environmentally friendly, as it uses water-based inks and requires less energy.

Offset Printing vs Flexographic Printing: Comparing the Two

When comparing offset printing vs flexographic printing, several factors come into play. While offset printing is renowned for its superior image quality and color accuracy, flexographic printing is praised for its versatility and efficiency in handling diverse materials. Let’s delve deeper into these differences.

Print Quality and Consistency

Offset printing is the go-to choice for projects demanding high-resolution images and consistent color reproduction. The precision of this method ensures that every print is identical, making it suitable for high-end publications and marketing materials. On the other hand, flexographic printing, though not as precise as offset, is adequate for general packaging and labeling needs.

Cost Considerations

Cost is a significant factor when choosing between these two methods. Offset printing can be more expensive due to the setup costs involved in creating plates. However, it becomes cost-effective for large print runs. Flexographic printing, with its faster setup and lower costs, is ideal for bulk printing, especially for packaging. For a deeper understanding of the cost implications, check out this cost analysis of offset printing.

Environmental Impact

With increasing awareness about environmental sustainability, the ecological impact of printing methods is crucial. Flexographic printing is typically more eco-friendly due to its use of water-based inks and energy-efficient processes. However, offset printing can also be sustainable when using soy-based inks and recycled paper.

Choosing the Right Method for Your Business

Deciding between offset printing vs flexographic printing depends on several factors, including the type of material, the desired print quality, and budget constraints. Businesses should assess their specific needs and consult with print technology experts to make the best choice. For more tailored advice, explore how offset printing benefits small businesses.

Industry Applications

Offset printing is widely used in industries that require high-quality printed materials, such as publishing and advertising. Flexographic printing is primarily employed in the packaging industry, where speed and cost-effectiveness are paramount. Understanding the industry-specific applications of each method can guide businesses in their decision-making process.

Technological Innovations

Both offset and flexographic printing have seen significant technological advancements in recent years. Innovations such as AI and IoT in printing have enhanced precision, efficiency, and quality, further blurring the lines between the two methods.

Conclusion

The debate of offset printing vs flexographic printing is not about which is better overall, but rather which is more suited to your specific needs. By understanding the strengths and limitations of each technique, businesses can make informed decisions that align with their goals and environmental commitments.

FAQs

What is the main advantage of offset printing?

Offset printing is renowned for its high-quality and consistent print results, making it ideal for projects requiring detailed images and vibrant colors.

Is flexographic printing environmentally friendly?

Yes, flexographic printing is considered more environmentally friendly due to its use of water-based inks and efficient energy use.

Which printing method is more cost-effective?

Flexographic printing is generally more cost-effective for large-volume orders, while offset printing becomes economical for high-quality large-scale productions.

This article contains affiliate links. We may earn a commission at no extra cost to you.