In today’s rapidly evolving world of technology, the realm of printing has witnessed significant advancements. Two of the most prominent methods that have risen to the forefront are Offset Printing and 3D Printing. Both have unique characteristics and serve different purposes, but how do they compare? This article explores the differences, uses, and future prospects of these two fascinating technologies.

Understanding the Basics of Offset Printing

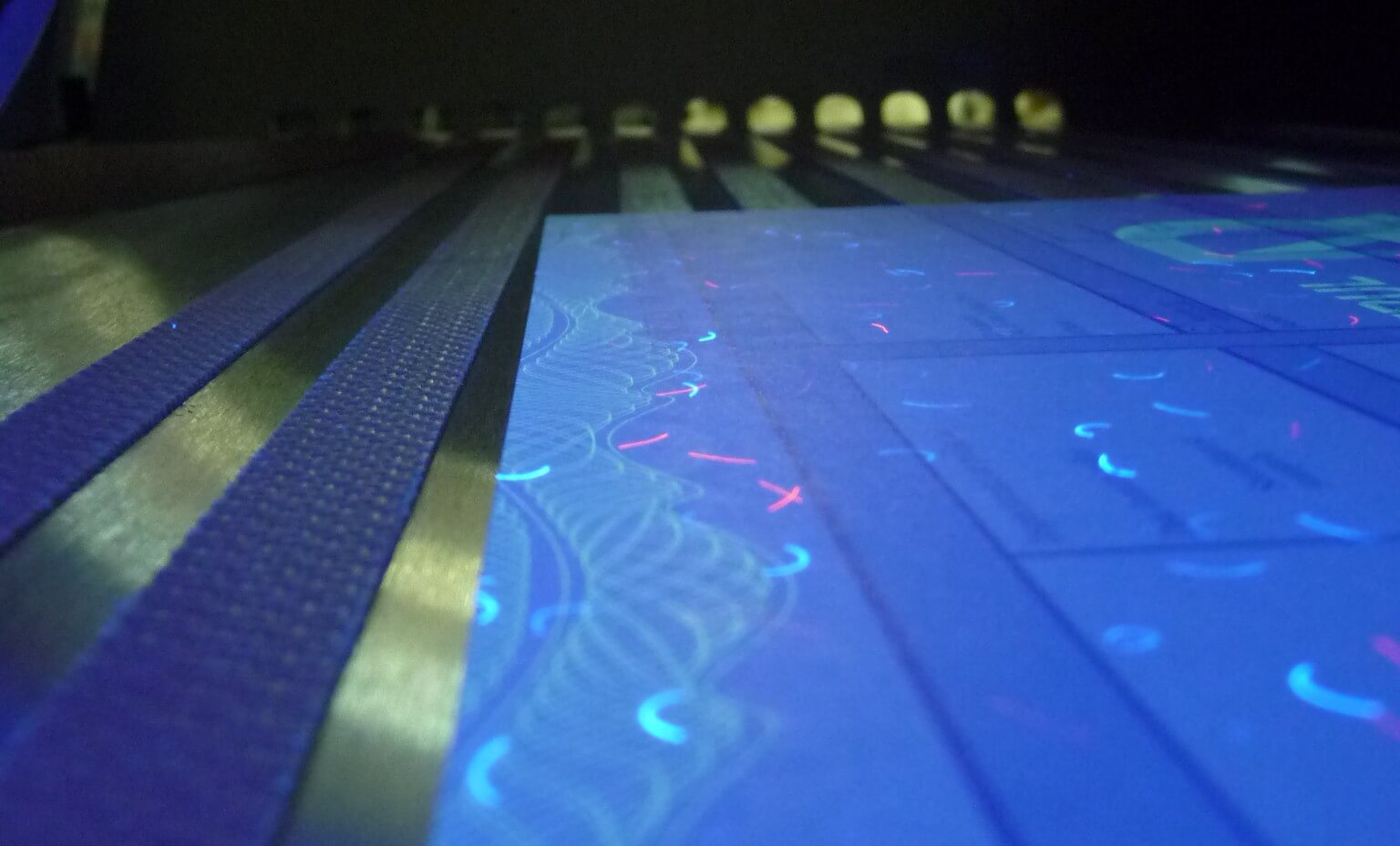

Offset Printing is a traditional printing technique that involves transferring ink from a plate to a rubber blanket and then onto a printing surface. It is highly regarded for its ability to produce high-quality, consistent images and is widely used for mass production such as in magazines, brochures, and newspapers.

How Offset Printing Works

The process begins with the creation of a plate, usually made of aluminum, which contains the image of the content to be printed. The plate is then inked, and the image is transferred to a rubber blanket, which finally presses the ink onto the paper. This indirect method ensures that the plate does not come into direct contact with the paper, prolonging the life of the printing plate.

Applications of Offset Printing

Offset Printing is predominantly used for high-volume applications. Its ability to produce consistent quality makes it ideal for printing magazines, books, newspapers, and stationery. For instance, offset printing for magazines is widely preferred due to its cost-effectiveness and quality.

Exploring the World of 3D Printing

3D Printing, on the other hand, is a relatively new technology that builds objects layer by layer from a digital file. This technique is transformative, allowing for the creation of complex and customized objects that would be difficult or impossible to produce with traditional methods.

How 3D Printing Works

Unlike Offset Printing, 3D Printing involves creating a three-dimensional object from a digital model. The process typically involves a 3D printer laying down successive layers of material until the object is complete. Materials used can range from plastics and metals to ceramics and even living cells.

Applications of 3D Printing

The versatility of 3D Printing allows it to be used in a wide range of industries, from healthcare to aerospace. It is particularly valued for its ability to produce prototypes and bespoke items. The technology is continually evolving, with ongoing research into new materials and methods.

Comparing Offset Printing and 3D Printing

Differences in Process and Application

While both Offset Printing and 3D Printing serve the purpose of creating physical items, their processes and applications are vastly different. Offset Printing is best suited for producing large quantities of high-quality printed materials, whereas 3D Printing excels in creating customized, complex items in small quantities.

Quality and Cost Considerations

The choice between Offset Printing and 3D Printing often comes down to the needs of the project. Offset Printing is generally more cost-effective for large print runs due to its low per-unit cost. However, 3D Printing offers unparalleled flexibility and customization, which can justify its higher cost for certain applications.

The Future of Printing Technologies

The future of both Offset Printing and 3D Printing is promising. As technology continues to advance, we can expect further innovations that will enhance the capabilities and applications of both methods. The integration of digital technologies is likely to play a significant role in their evolution.

Environmental Impact

Both printing methods are also becoming more environmentally friendly. Offset Printing has made strides in reducing waste and using sustainable materials, while 3D Printing is developing new materials and methods to minimize its environmental footprint.

Conclusion

In conclusion, both Offset Printing and 3D Printing have their unique advantages and are suited to different applications. Understanding their differences and capabilities allows businesses and individuals to make informed decisions about which method to utilize for their specific needs.

FAQ

1. What is the main difference between Offset Printing and 3D Printing?

The main difference lies in their process and application. Offset Printing is ideal for mass production of high-quality two-dimensional prints, while 3D Printing is used for creating three-dimensional objects, often in small quantities or for custom projects.

2. Which printing method is more cost-effective for large volumes?

Offset Printing is generally more cost-effective for large volumes due to its lower per-unit cost, especially when producing high quantities of the same design.

3. Can 3D Printing be used for mass production?

While 3D Printing is primarily used for prototyping and custom projects, advancements in technology are making it increasingly viable for certain types of mass production, particularly where customization is required.

For more information on the differences between these printing methods, you can visit this detailed comparison.

This article contains affiliate links. We may earn a commission at no extra cost to you.