In the ever-evolving world of print media, offset printing technology advancements have continued to play a pivotal role in shaping the industry. As businesses increasingly rely on high-quality printed materials, understanding the latest advancements in offset printing becomes crucial. This article delves into the transformative changes and innovations within this field to enhance your knowledge and keep you up-to-date.

The Evolution of Offset Printing

Offset printing has a rich history that dates back to the early 20th century. Initially, it revolutionized the printing industry by offering a cost-effective way to produce large volumes of high-quality prints. Today, the technology has evolved significantly, incorporating modern techniques and materials to meet the demands of contemporary businesses.

Understanding Offset Printing Technology

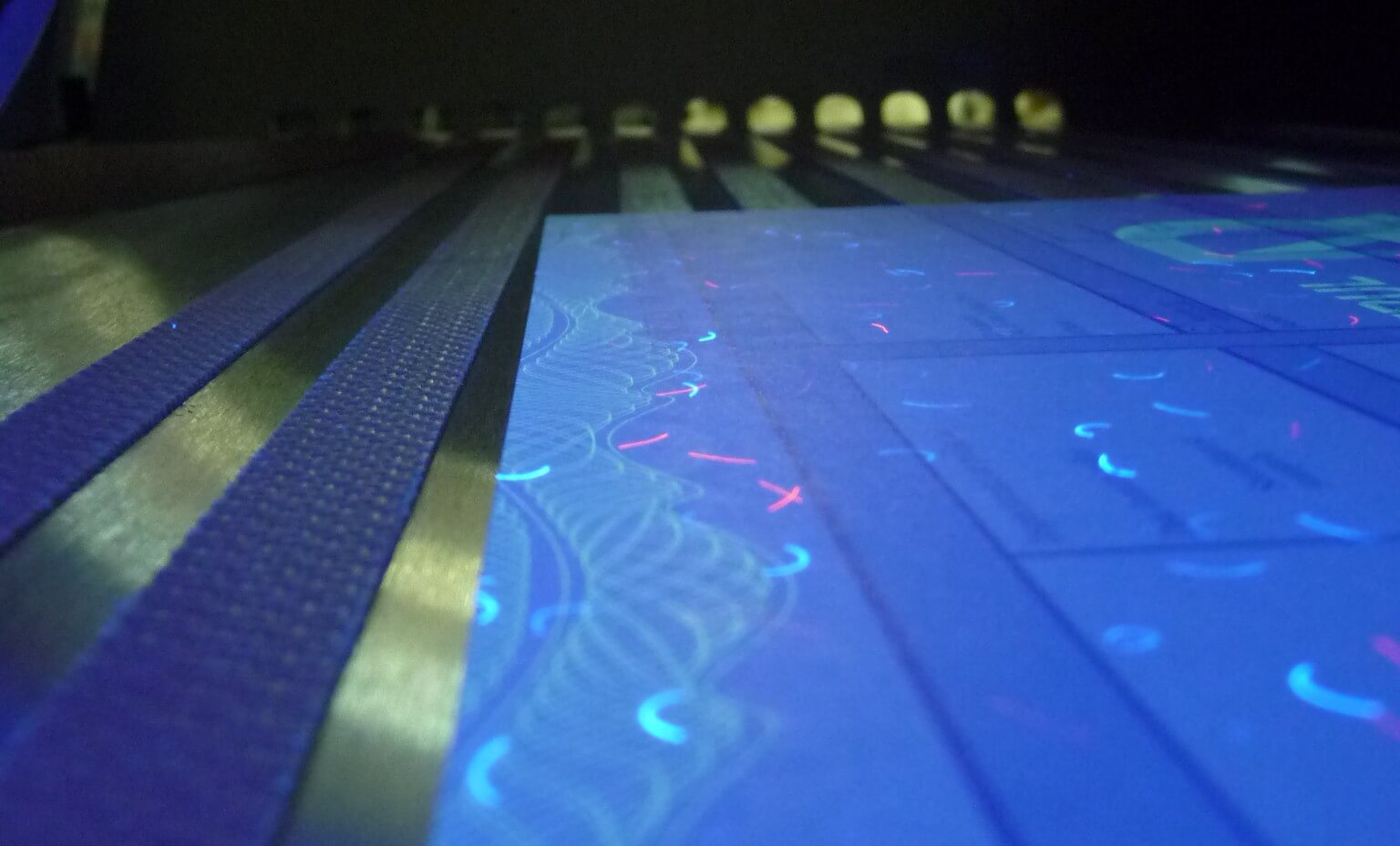

At its core, offset printing involves transferring ink from a plate to a rubber blanket and then onto the printing surface. This process ensures precise image reproduction and vibrant colors, making it a preferred choice for businesses seeking premium-quality prints.

Key Components of Offset Printing

- Plates: These are typically made of aluminum and are used to transfer images onto the rubber blanket.

- Rubber Blankets: These act as intermediaries, ensuring even ink distribution on the substrate.

- Inks: High-quality inks are essential for vibrant and long-lasting prints.

Recent Technological Advancements

The offset printing industry has witnessed several technological breakthroughs in recent years. These advancements have improved efficiency, quality, and sustainability, making offset printing more attractive to businesses.

Automation and Robotics

Automation has become a game-changer in offset printing. With automated systems and robotic arms, printing presses can now operate with minimal human intervention, reducing errors and increasing productivity.

Enhanced Plate Technology

Improvements in plate technology have led to sharper images and faster production times. Advanced plates require less water and chemicals, aligning with the industry’s push for eco-friendly solutions.

Ink Innovations

Recent developments in ink formulations have resulted in brighter colors and faster drying times. These inks are also more environmentally friendly, reducing the carbon footprint of printing operations.

Sustainability in Offset Printing

As sustainability becomes a top priority for businesses, the offset printing industry is actively adopting greener practices. From using recycled paper to reducing waste, these efforts aim to minimize the environmental impact of printing.

Eco-Friendly Materials

Many printing companies are now using recycled paper and soy-based inks, which are less harmful to the environment compared to traditional materials.

Waste Reduction Strategies

Offset printing facilities are implementing waste reduction strategies, such as recycling excess materials and optimizing print runs to minimize wastage.

The Future of Offset Printing

The future of offset printing is promising, with continuous advancements in technology and materials. As businesses seek innovative ways to engage their audiences, offset printing will remain a crucial tool for delivering high-quality printed materials.

Integration with Digital Technologies

The integration of digital technologies with offset printing is expected to offer even greater flexibility and customization options for businesses.

Personalization and Customization

With improved data analytics and printing techniques, businesses can now create personalized marketing materials that resonate with their target audience.

Conclusion

In conclusion, offset printing technology advancements continue to drive the industry forward, offering businesses new opportunities for growth and innovation. By staying informed about these developments, you can leverage the power of offset printing to enhance your brand’s visibility and impact.

Related Links

For more information about offset printing for specific needs such as newsletters, business cards, and graphic design, visit our website.

For a detailed comparison between offset and digital printing, check out this external resource.

FAQs

What is offset printing used for?

Offset printing is primarily used for producing high-quality prints in large volumes, such as brochures, magazines, and packaging materials.

How does offset printing differ from digital printing?

Offset printing uses plates to transfer images onto paper, while digital printing directly applies the image using digital files. Offset is often preferred for large runs due to its cost-effectiveness and quality.

Are there eco-friendly options in offset printing?

Yes, many offset printing companies offer eco-friendly options, such as recycled paper and soy-based inks, to minimize environmental impact.

This article contains affiliate links. We may earn a commission at no extra cost to you.