The Offset Printing Process is a fascinating and intricate method that has revolutionized the printing industry. For business professionals, understanding the nuances of this process can provide valuable insights into choosing the right printing solutions. In this article, we’ll explore the offset printing process in detail, highlighting its components, benefits, and best practices.

What is Offset Printing?

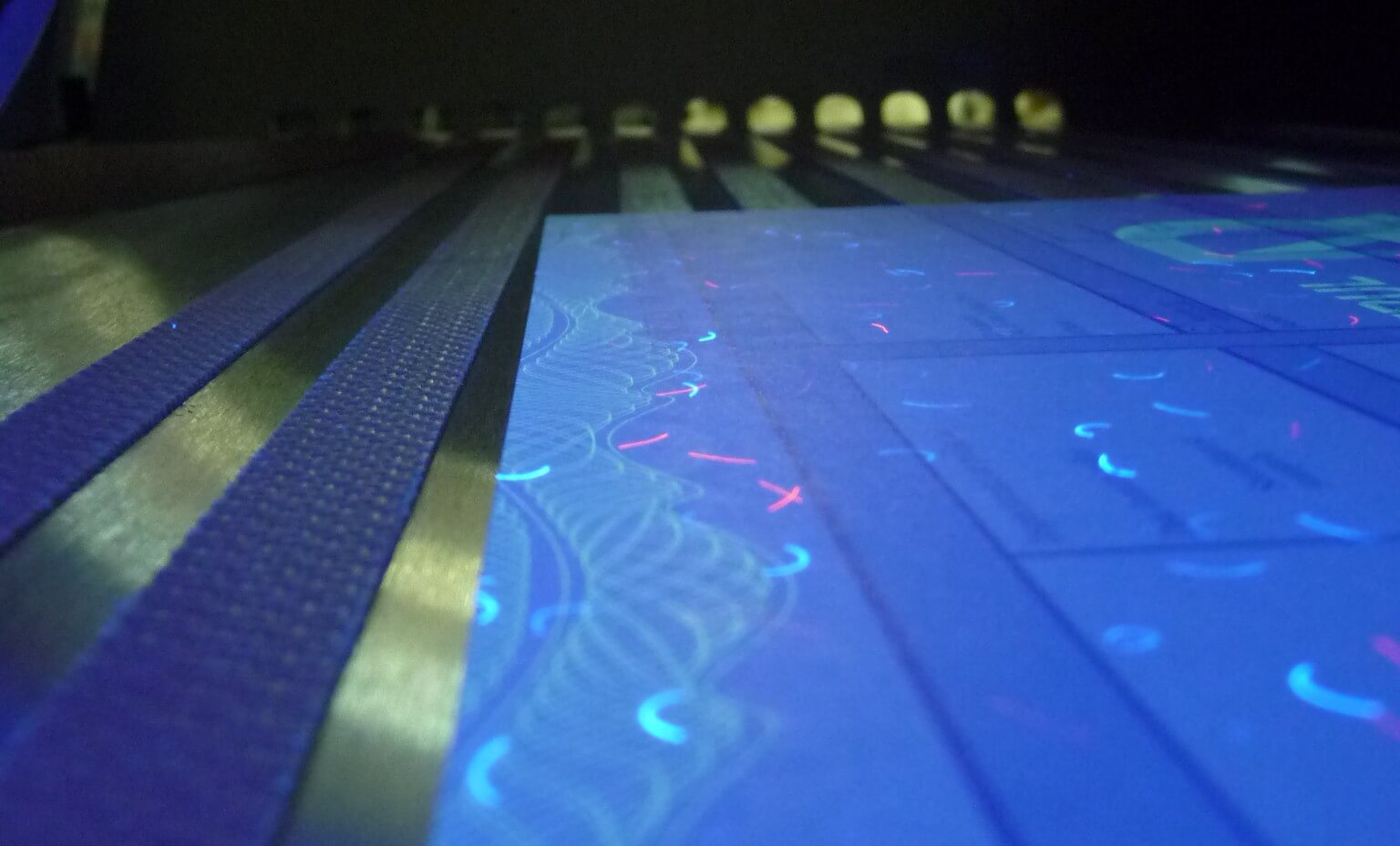

Offset Printing is a widely used printing technique where an inked image is transferred or offset from a plate to a rubber blanket and then to the printing surface. This method is popularly used for high-volume commercial printing like newspapers, magazines, brochures, and books.

History of Offset Printing

The history of offset printing can be traced back to the early 20th century. Initially developed to enhance the printing process, it quickly became the standard for commercial printing due to its efficiency and quality output.

How Does the Offset Printing Process Work?

Understanding the offset printing process involves knowing the role of each component involved in the printing mechanism:

Plates

Plates are a vital part of the offset printing process. Made usually of metal, these plates are etched with the image to be printed. Each color in a print job may require its own separate plate.

Rubber Blankets

The rubber blanket is what ultimately transfers the image from the plate onto the paper. These blankets ensure sharp and clear prints by seamlessly adopting the print layout.

Impression Cylinder

The impression cylinder is responsible for pressing the paper against the plate and blanket, ensuring consistent image transfer.

Benefits of Offset Printing

The offset printing process offers several notable advantages:

High-Quality Images

One of the hallmarks of offset printing is its ability to produce high-quality images with accurate color reproduction and sharp details.

Cost-Effective for Large Prints

For high-volume print jobs, offset printing is typically more cost-effective compared to other printing methods. It efficiently handles large quantities without sacrificing quality.

Versatility

The offset printing process is highly versatile, accommodating a wide range of materials, from paper to cardboard to even plastic.

Offset Printing Inks

Inks used in offset printing are specially formulated for optimal performance on printing plates. Choosing the right ink is crucial for achieving the desired print quality and durability. [More In-depth Comparison with Digital](https://ordant.com/what-is-offset-printing/)

Differences Between Offset and Digital Printing

It’s important to recognize the differences between offset and digital printing to make informed decisions about your business’s printing needs. [Comparison with Digital Printing](https://www.kaocollins.com/inktank/offset-vs-digital-printing/)

Best Practices for Offset Printing

To maximize the benefits of the offset printing process, here are some best practices to consider:

Select the Right Paper

Using the appropriate paper can drastically impact the quality of the final print. Coated papers often yield the best results in terms of image clarity and vibrancy.

Regular Maintenance of Equipment

Maintaining the printing press and ensuring that all components are in top working condition is essential for minimizing errors and downtime.

Collaborate with Experienced Professionals

Working with experienced professionals who understand the intricacies of the offset printing process can be immensely beneficial, ensuring optimal results and efficiency.

Future of Offset Printing

Despite the advent of digital technologies, the future of offset printing remains bright. Continuous innovations are enhancing its efficiency, quality, and scope, making it a staple in the printing industry.

Integration with Digital Technologies

There’s a growing trend towards integrating offset and digital technologies to leverage the strengths of both methods, resulting in hybrid solutions that offer unmatched precision and speed.

Sustainability and Eco-friendliness

The push towards sustainability in printing is seeing the emergence of eco-friendly inks and materials, thereby reducing the environmental impact of the offset printing process.

Conclusion

The offset printing process provides a robust and reliable solution for high-quality commercial printing. By understanding its elements and adhering to best practices, businesses can harness its full potential to produce outstanding print materials. If you’re interested in learning more about technological advancements in printing, consider exploring [AI’s impact on printing](https://fullcolorprintingfirm.com/ai-iot-in-printing-14/) or the benefits drawn from [Increased Equipment Lifespan](https://fullcolorprintingfirm.com/increased-equipment-lifespan/).

FAQs

What materials can be printed using offset printing?

Offset printing is versatile, accommodating a range of materials including paper, cardboard, and plastic.

Why is offset printing more cost-effective for large volumes?

The equipment setup in offset printing is fixed, leading to decreased per-unit costs as print volume increases, making it ideal for large print jobs.

How does offset printing ensure high-quality prints?

The use of precise metal plates, durable rubber blankets, and superior inks in offset printing contributes to its high-quality output and fidelity.

This article contains affiliate links. We may earn a commission at no extra cost to you.