In the realm of business branding, creating an impactful first impression is crucial. One of the most effective ways to achieve this is through high-quality branding materials. Among the various printing techniques available, offset printing stands out as a preferred choice for many professionals due to its superior quality and cost-effectiveness for large volumes. In this guide, we will delve into the world of offset printing and explore how it can enhance your branding efforts.

What is Offset Printing?

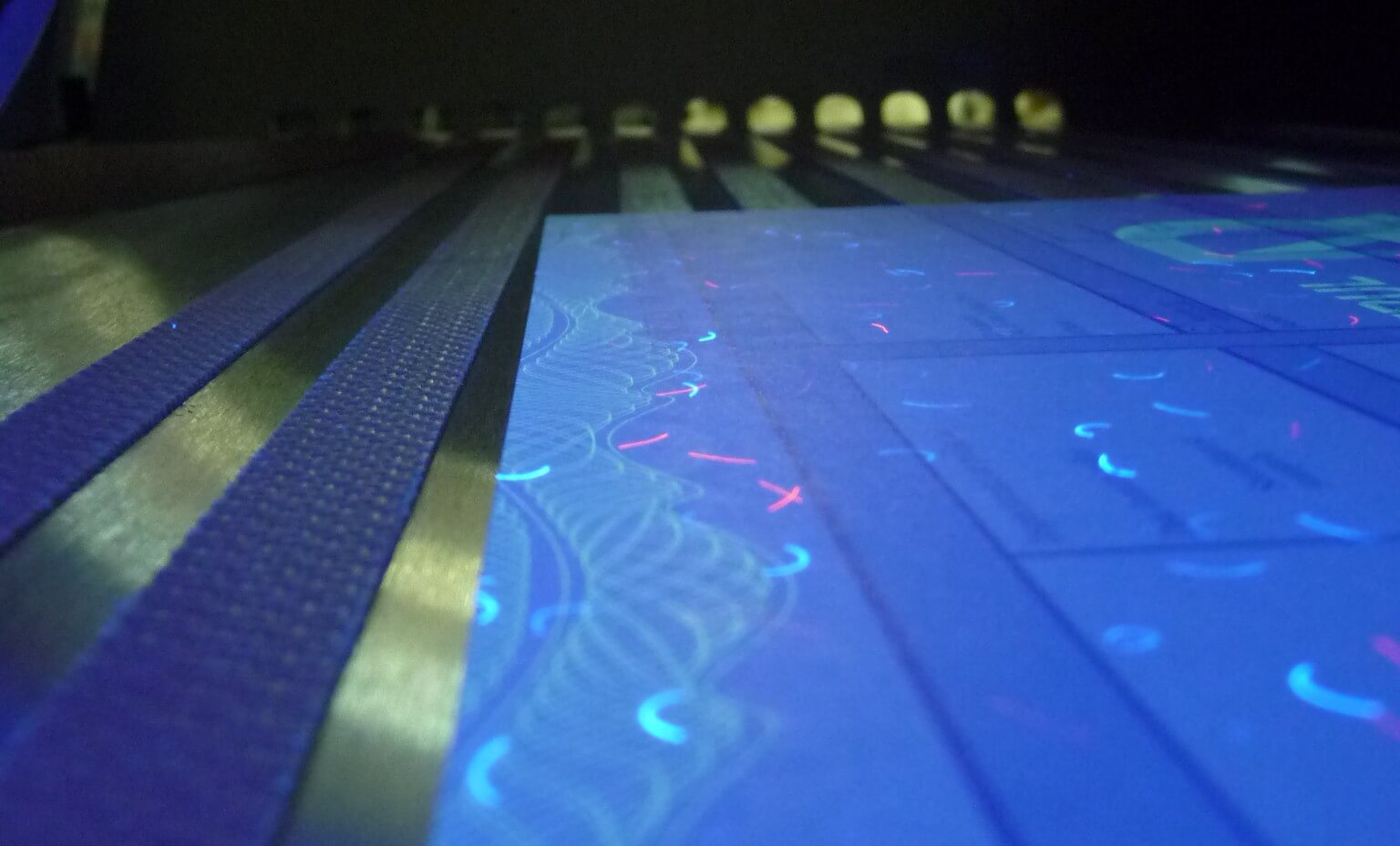

Offset printing is a widely used printing technique where the image is transferred (or ‘offset’) from a plate to a rubber blanket, and then onto the printing surface. This method is particularly effective for producing large quantities of high-quality prints, making it ideal for branding materials such as business cards, brochures, and flyers.

Why Choose Offset Printing for Branding Materials?

When it comes to branding materials, quality is paramount. Here are some reasons why offset printing is a great choice:

Superior Image Quality

One of the main advantages of offset printing is its ability to produce clear, detailed images with rich color density. This is crucial for branding materials that need to capture attention and convey professionalism.

Cost-Effectiveness for Large Volumes

While the initial setup cost for offset printing can be higher than digital printing, the per-unit cost decreases significantly with larger print runs. This makes it an economical choice for businesses looking to produce branding materials in bulk. Learn more about the cost of offset printing.

Versatility in Printing Surfaces

Offset printing can be used on a wide range of surfaces, including paper, cardboard, and even plastic. This versatility allows businesses to create a variety of branding materials tailored to their specific needs.

Key Components of Offset Printing

Understanding the components involved in offset printing can help you make informed decisions about your branding materials. Here are the main components:

Printing Plates

The process begins with creating printing plates, which hold the image to be printed. These plates are typically made of metal, making them durable and capable of producing high-quality prints.

Rubber Blankets

Once the image is transferred from the plate, it is then passed onto a rubber blanket. The blanket’s flexibility allows it to conform to various surfaces, ensuring consistent print quality.

Ink and Water Balance

Maintaining the right balance between ink and water is crucial in offset printing to ensure sharp and vibrant images. Skilled technicians adjust this balance to achieve optimal results.

Applications of Offset Printing in Branding

Offset printing is widely used in various branding materials due to its ability to produce high-quality prints. Here are some common applications:

Business Cards

Business cards are an essential part of any professional’s branding toolkit. Offset printing ensures that these cards are printed with crisp text and vibrant colors, leaving a lasting impression.

Brochures and Flyers

Brochures and flyers are effective tools for marketing and brand promotion. With offset printing, these materials can be produced in bulk without compromising on quality.

Stationery

Custom stationery like letterheads and envelopes can enhance your brand’s identity. Discover how offset printing for stationery can elevate your brand’s image.

How to Prepare for Offset Printing

Preparing your branding materials for offset printing requires careful planning and attention to detail. Here are some steps to ensure a smooth process:

Design Considerations

Ensure your designs are high resolution and compatible with the printing process. Pay attention to color matching and use CMYK color models for accurate reproduction.

Proofing and Approval

Before the final print, request a proof to review the design. This step is crucial to catch any errors and make necessary adjustments before mass production.

Choosing the Right Printing Partner

Select a reliable printing partner with experience in offset printing. Check reviews and samples of their work to ensure quality and professionalism. For more insights, visit Vistaprint.

Offset Printing vs. Digital Printing

While both printing methods have their advantages, it’s essential to choose the one that best suits your needs. Offset printing is ideal for large runs and offers superior image quality, while digital printing is more suitable for smaller quantities and quick turnarounds. For a detailed comparison, visit FSSI.

Conclusion

Offset printing remains a reliable and efficient choice for producing high-quality branding materials. By understanding its advantages and applications, businesses can leverage this technique to enhance their brand image effectively. Whether you’re printing business cards, brochures, or stationery, offset printing offers the quality and versatility needed to make your brand stand out.

Frequently Asked Questions

What is the cost difference between offset and digital printing?

While offset printing has a higher initial setup cost, it becomes more cost-effective for larger print runs compared to digital printing.

How does offset printing ensure color accuracy?

Offset printing uses the CMYK color model and skilled technicians to maintain color accuracy throughout the printing process.

Can offset printing be used for custom designs?

Yes, offset printing is highly versatile and can be used for custom designs on a variety of materials, including paper and plastic.

This article contains affiliate links. We may earn a commission at no extra cost to you.