In the world of printing, Offset Printing and Color Separation play pivotal roles in ensuring high-quality output is achieved. This article delves into the intricacies of these processes, providing a thorough understanding for business professionals seeking to enhance their printing knowledge.

Understanding Offset Printing

Offset printing is a widely used printing technique where the inked image is transferred from a plate to a rubber blanket, then to the printing surface. This method is popular because it provides consistent quality and is ideal for producing large volumes.

History and Evolution

The history of offset printing dates back to the early 20th century. Its evolution has been marked by technological advancements that have improved its efficiency and quality. Understanding its history helps appreciate its significance in today’s printing industry.

How Offset Printing Works

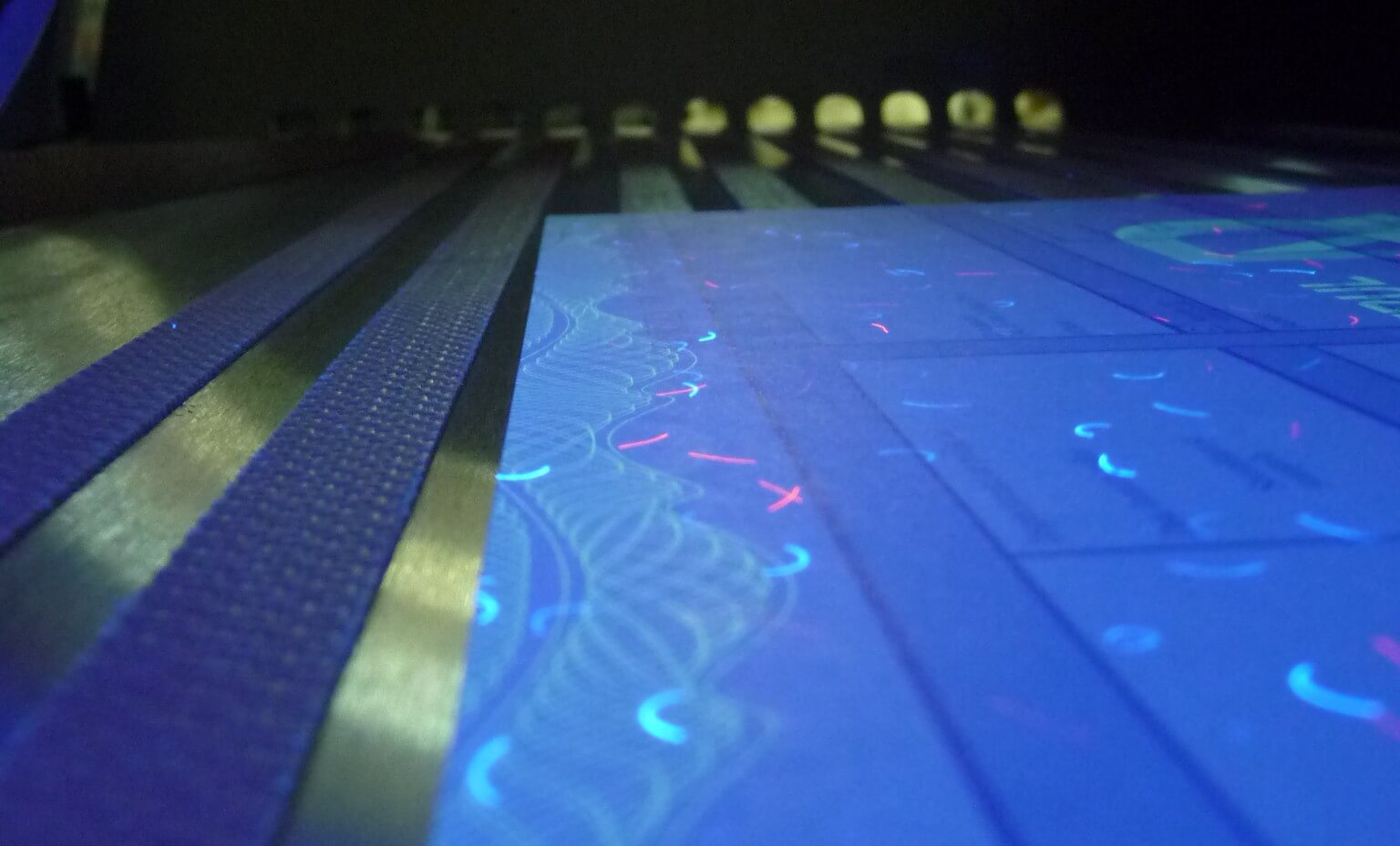

Offset printing involves several key steps: plate creation, ink application, and image transfer. The process begins with creating a plate, which holds the image to be printed. Ink is then applied to the plate, which transfers the image onto a rubber blanket, and finally onto the printing surface.

Exploring Color Separation

Color separation is crucial in printing, ensuring that images are reproduced accurately in full color. This process involves breaking down an image into its primary colors, which are then printed in layers to achieve the final image.

The Science Behind Color Separation

Color separation relies on the CMYK color model, which stands for Cyan, Magenta, Yellow, and Key (Black). These colors are used in varying combinations to produce the full spectrum of colors in printed materials.

Importance in Modern Printing

In modern printing, color separation is vital for achieving vibrant and accurate colors. This is especially important in industries like advertising and publishing, where visual appeal is critical.

Benefits of Offset Printing and Color Separation

The combination of offset printing and color separation offers numerous advantages. These include high quality, cost-effectiveness for large runs, and the ability to print on various surfaces.

High-Quality Prints

One of the primary benefits of offset printing is its ability to produce high-quality prints with sharp details and vibrant colors, thanks to color separation.

Cost-Effectiveness

For businesses requiring large print runs, offset printing is cost-effective. The initial setup costs are offset by the low cost per unit in large volumes.

Versatility

Offset printing can be used on a variety of surfaces, including paper, cardboard, and plastic. This versatility makes it suitable for a wide range of applications, from newsletters to business cards.

Challenges in Offset Printing and Color Separation

Despite its benefits, offset printing and color separation come with challenges, such as setup time and the need for skilled operators.

Setup Time

The setup process for offset printing can be time-consuming, requiring precise calibration and alignment of plates and colors.

Operator Skill

Skilled operators are essential for managing the complex processes involved in offset printing and color separation, ensuring that the final output meets quality standards.

Technological Advances in Printing

Recent technological advances have significantly improved offset printing and color separation, making them more efficient and accessible.

Digital Enhancements

Digital technology has introduced enhancements like computer-to-plate systems, which streamline the offset printing process and reduce errors.

Environmental Considerations

Modern offset printing processes are increasingly focused on sustainability, with innovations aimed at reducing waste and energy consumption.

Applications of Offset Printing and Color Separation

These printing techniques are used in various industries, demonstrating their versatility and importance.

Advertising and Marketing

In advertising, high-quality printed materials are crucial for creating compelling campaigns. Offset printing provides the quality needed for impactful visuals.

Publishing

In publishing, books and magazines benefit from the sharp images and vibrant colors achieved through color separation and offset printing. Learn more about our magazine printing services.

Future of Offset Printing and Color Separation

The future of offset printing and color separation is promising, with continuous innovations enhancing their capabilities.

Emerging Trends

Emerging trends like automation and AI integration are set to revolutionize the printing industry, increasing efficiency and reducing costs.

Potential Challenges

While the future is bright, challenges such as adapting to new technologies and maintaining environmental sustainability remain.

Conclusion

In conclusion, offset printing and color separation are integral to the printing industry, offering high-quality, cost-effective solutions for businesses. As technology advances, these techniques will continue to evolve, meeting the demands of modern printing needs. For further insights into printing techniques, visit Focus Label.

FAQs

What is the main advantage of offset printing?

The main advantage of offset printing is its ability to produce high-quality prints at a low cost per unit for large volumes.

How does color separation work in printing?

Color separation works by breaking down an image into its primary colors (CMYK) for accurate reproduction in print.

Is offset printing environmentally friendly?

Modern offset printing processes are increasingly focused on sustainability, with efforts to reduce waste and energy consumption.

This article contains affiliate links. We may earn a commission at no extra cost to you.