Nylon has become a go-to material for many enthusiasts and professionals seeking durable, flexible, and high-performance 3D printed parts. Known for its strength and resilience, nylon offers unique advantages over other common filaments, but it also presents challenges that require specific techniques and careful preparation. This comprehensive resource explores the essential methods, troubleshooting tips, and practical uses of nylon in additive manufacturing. Whether you’re new to working with this material or looking to refine your process, you’ll find actionable advice and insights to help you achieve reliable, high-quality results.

For those interested in sustainable practices, you may also want to explore eco friendly 3D printing to reduce waste and environmental impact in your projects.

Understanding Nylon as a 3D Printing Material

Nylon is a synthetic polymer known for its high tensile strength, flexibility, and resistance to abrasion and chemicals. When used in 3D printing, it produces parts that are both tough and slightly flexible, making it ideal for functional prototypes, mechanical components, and end-use products. Compared to PLA or ABS, nylon stands out for its durability and ability to withstand repeated stress without cracking.

However, nylon is also hygroscopic, meaning it absorbs moisture from the air. This property can lead to print defects if the filament is not properly stored and dried before use. Understanding the characteristics of nylon and how it compares to other materials is crucial for successful printing. For a broader look at material options, check out this 3D printing materials overview.

Essential Techniques for Printing with Nylon

Achieving optimal results with nylon requires attention to several key factors, from printer setup to environmental controls. Below are the most important techniques to master when working with this versatile filament.

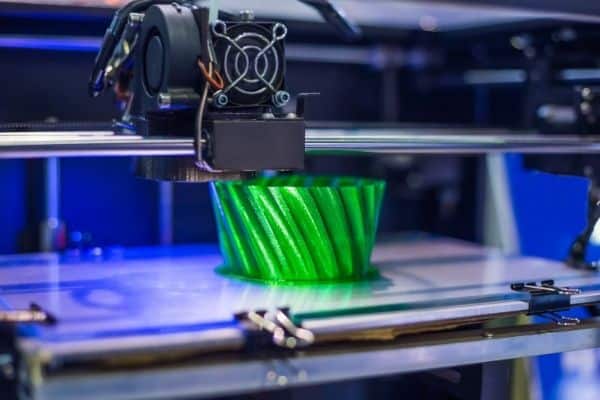

Printer Preparation and Hardware Considerations

Not all desktop 3D printers are equipped to handle nylon. Because of its higher melting point and tendency to warp, you’ll need a printer with a heated bed (preferably up to 100°C or more) and an all-metal hotend capable of reaching at least 250°C. An enclosed build chamber is highly recommended to maintain consistent temperatures and reduce warping.

Filament Storage and Drying

Because nylon absorbs moisture quickly, always store it in an airtight container with desiccant packs. If the filament has been exposed to air, dry it in a filament dryer or a conventional oven at 70–80°C for 4–6 hours before printing. Printing with wet nylon can result in bubbling, stringing, and weak parts.

Bed Adhesion and Surface Preparation

Nylon’s tendency to warp makes bed adhesion a critical concern. Use a bed surface such as Garolite (G10/FR4), PEI, or a glue stick on glass to improve first-layer bonding. Some users also find success with blue painter’s tape or specialized adhesion sheets. Always clean the build surface before printing to remove oils and dust.

Optimal Print Settings for Nylon

- Nozzle temperature: 240–270°C (check manufacturer’s recommendation)

- Bed temperature: 60–100°C

- Print speed: 30–60 mm/s for best results

- Cooling: Minimal or off to prevent warping

- Enclosure: Strongly recommended for larger parts

Fine-tuning these parameters can help minimize warping, stringing, and layer separation. Start with the manufacturer’s guidelines and adjust based on your specific printer and environment.

Tips for Successful Nylon Prints

Even with the right equipment and settings, nylon can be challenging. Here are some practical tips to improve your results:

- Keep filament dry: Always dry nylon before use and store it properly between prints.

- Use a brim or raft: Adding a brim or raft can help anchor prints and reduce warping.

- Print in a warm room: Avoid drafts and temperature fluctuations during printing.

- Monitor first layers: Watch the first few layers to ensure proper adhesion and adjust Z-offset if needed.

- Post-process with care: Nylon can be sanded, dyed, or machined, but use sharp tools and moderate speeds to avoid melting.

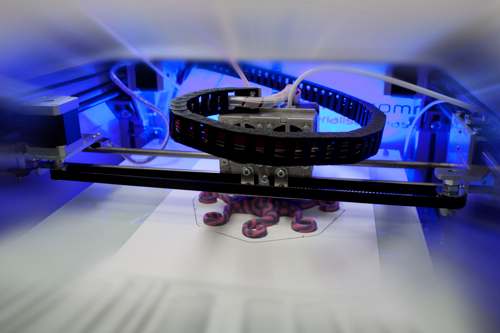

Popular Applications for Nylon 3D Printing

The unique properties of nylon make it suitable for a wide range of applications. Its combination of strength, flexibility, and chemical resistance is valued in both industrial and creative contexts.

- Functional prototypes: Nylon’s durability makes it ideal for prototyping moving parts, gears, and hinges.

- Mechanical components: Used for bushings, bearings, and structural parts that require impact resistance.

- End-use products: Common in custom tools, fixtures, and consumer goods that demand longevity.

- Wearables and robotics: Flexible yet tough, nylon is used for joints, straps, and robotic components.

For those interested in sustainable material choices, consider reading about recycled filaments for 3D printing and biodegradable 3D printing materials for eco-conscious alternatives.

Comparing Nylon to Other 3D Printing Materials

Nylon is often compared to PLA and ABS due to its mechanical properties and printability. While PLA is easy to print and biodegradable, it lacks the toughness and flexibility of nylon. ABS offers better impact resistance than PLA but is more prone to warping and emits fumes during printing. Nylon bridges the gap by providing strength, flexibility, and chemical resistance, though it requires more careful handling.

For a detailed breakdown, see this PLA vs ABS comparison to understand how nylon fits into the broader landscape of 3D printing materials.

Advanced Techniques and Troubleshooting

As you gain experience, you may want to experiment with advanced nylon blends (such as carbon fiber or glass-filled variants) for even greater strength and stiffness. These materials often require hardened steel nozzles due to their abrasive nature.

Common issues when printing with nylon include warping, stringing, and poor layer adhesion. To address these:

- Warping: Increase bed temperature, use an enclosure, and add brims or rafts.

- Stringing: Dry filament thoroughly and adjust retraction settings.

- Layer separation: Raise nozzle and bed temperatures, and minimize cooling fan usage.

If you’re considering upgrading your equipment, explore professional options like the latest 3D printers for advanced materials to achieve consistent, high-quality results.

FAQ

What are the main advantages of using nylon for 3D printing?

Nylon offers a unique combination of strength, flexibility, and chemical resistance. It’s ideal for functional parts that require durability and can withstand repeated mechanical stress, making it suitable for prototypes, mechanical components, and end-use products.

How should nylon filament be stored to prevent print issues?

Always store nylon filament in an airtight container with desiccant packs to prevent moisture absorption. If the filament feels brittle or prints with bubbles and stringing, dry it in a filament dryer or oven before use.

Can nylon be printed on any 3D printer?

Not all printers are suitable for nylon. You’ll need a machine with a heated bed, an all-metal hotend capable of reaching at least 250°C, and ideally an enclosed build chamber to maintain temperature stability and reduce warping.