Multimaterial 3D printing has rapidly evolved from a niche capability to a transformative technology across industries. By enabling the fabrication of objects with multiple materials in a single build process, this approach unlocks new possibilities for functional prototypes, end-use parts, and complex assemblies. Whether you’re a product designer, engineer, or hobbyist, understanding the methods and real-world uses of this technology can help you make more informed decisions and achieve better results.

In this guide, we’ll explore the most common techniques for combining different materials during additive manufacturing, examine the advantages and limitations, and highlight how these innovations are being applied in fields such as healthcare, automotive, and consumer products. For those interested in refining their finished prints, resources like sanding and finishing 3D prints can further enhance the quality and functionality of multimaterial creations.

Understanding Multimaterial Additive Manufacturing

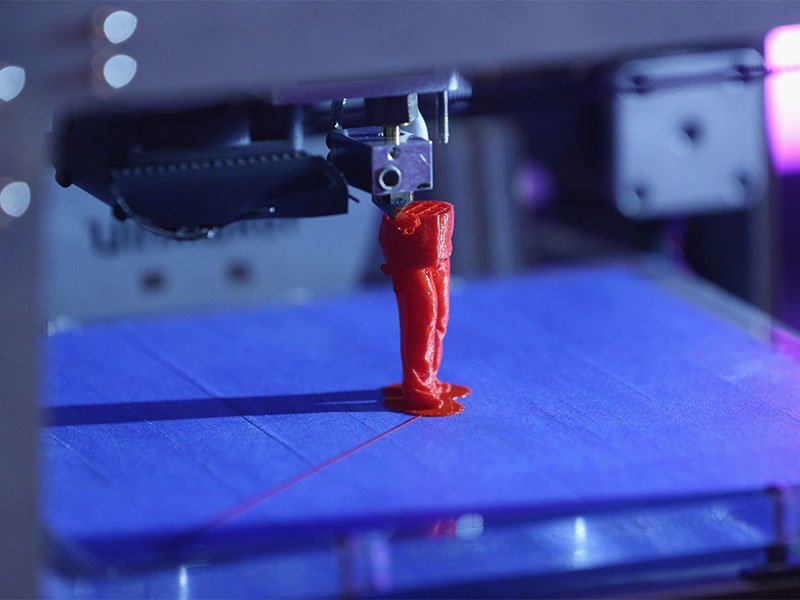

The core idea behind multimaterial fabrication is to deposit, fuse, or cure different substances layer by layer, often within the same print job. This allows for the creation of parts with varying mechanical, thermal, or optical properties, and even objects that combine rigid and flexible regions. The process can involve plastics, metals, ceramics, or even biological materials, depending on the printer and method used.

The ability to print with more than one material is not just about aesthetics or color. It’s about function—combining conductive and insulating elements, integrating soft-touch surfaces with durable frames, or embedding support materials that dissolve away after printing. As a result, designers can address challenges that were previously unsolvable with single-material approaches.

Key Techniques for Printing with Multiple Materials

Several technologies enable the integration of different materials during the 3D printing process. The most common methods include:

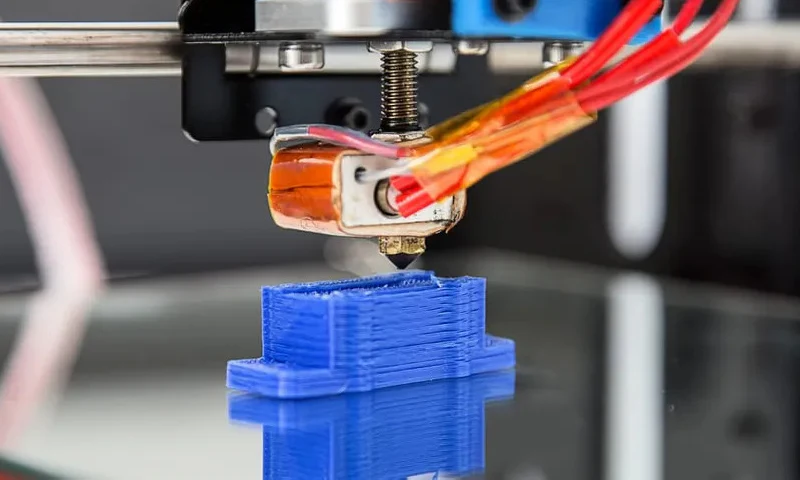

- Dual-Extrusion Fused Deposition Modeling (FDM): This approach uses two or more print heads, each loaded with a different filament. It’s widely used for combining colors, rigid and flexible plastics, or structural and support materials. Careful calibration is required to avoid cross-contamination and ensure strong layer adhesion.

- PolyJet and MultiJet Printing: These inkjet-based systems can deposit droplets of photopolymer resins, which are then cured with UV light. By blending different resins, they can produce parts with gradients in color, hardness, or transparency. This method is popular for prototyping and medical models.

- Selective Laser Sintering (SLS) and Powder Bed Fusion: While traditionally used for single-material builds, recent advances allow for the sequential or simultaneous deposition of different powders, including metals and polymers. This enables the creation of composite parts with tailored properties.

- Direct Energy Deposition (DED): Used primarily for metals, DED systems can feed multiple powders or wires into a melt pool created by a laser or electron beam. This technique is valuable for repairing or adding features to existing components with different alloys.

- Hybrid and Custom Solutions: Some advanced setups combine additive and subtractive processes, or use robotic arms to switch between material sources, expanding the range of possible combinations.

Advantages and Challenges of Multimaterial 3D Printing

The benefits of using more than one material in a single print are substantial. Designers can create integrated assemblies, reduce the need for post-processing, and achieve properties that would be impossible with traditional manufacturing. For example, printing a soft gasket directly onto a rigid housing eliminates assembly steps and potential leak points.

However, there are also challenges to consider:

- Material Compatibility: Not all materials bond well together. Differences in melting temperature, shrinkage, or chemical composition can lead to weak interfaces or warping. Understanding how to prevent defects is crucial—resources like how to prevent warping in prints offer practical tips.

- Printer Complexity: Machines capable of handling multiple materials are often more expensive and require more maintenance. Calibration, cleaning, and software setup can be more involved than with single-material printers.

- Design Constraints: Not every geometry is suitable for multimaterial fabrication. Overhangs, unsupported features, and intricate transitions between materials may require additional planning or support strategies.

- Post-Processing: Removing support materials, smoothing transitions, and achieving a high-quality finish can be more complex. Guides on post processing 3D prints can help users achieve professional results.

Real-World Applications Across Industries

The practical uses of combining materials during additive manufacturing are expanding rapidly. Some of the most impactful applications include:

- Healthcare: Custom prosthetics, dental models, and anatomical replicas often require both rigid and flexible regions. Multimaterial techniques allow for more lifelike and functional medical devices.

- Automotive and Aerospace: Lightweight structures with integrated seals, vibration dampers, or electrical pathways can be produced in fewer steps, reducing assembly time and improving reliability.

- Consumer Products: From multi-color phone cases to wearables with embedded electronics, the ability to print with several materials enables rapid prototyping and short-run production of complex goods.

- Education and Research: Academic labs use these methods to explore new material combinations, test mechanical properties, and create teaching aids that demonstrate complex concepts.

Optimizing Print Quality and Material Transitions

Achieving seamless transitions between different materials is a key challenge in multimaterial additive manufacturing. Print settings such as temperature, extrusion rate, and cooling must be carefully tuned for each material. Some printers offer purge towers or wipe walls to prevent color or material contamination at the interface.

Post-processing steps—such as sanding, painting, or chemical smoothing—can further improve the appearance and performance of multimaterial prints. For those seeking to enhance the surface finish or durability, guides like painting 3D printed models provide actionable advice.

Choosing the Right Approach for Your Project

Selecting the best method for combining materials depends on your application, budget, and available equipment. For simple color changes or dual-material prints, a dual-extrusion FDM printer may suffice. For more advanced needs—such as producing parts with variable hardness or transparency—PolyJet or MultiJet systems offer greater flexibility, albeit at a higher cost.

It’s also important to consider post-processing requirements. Some projects may need additional steps to achieve the desired finish or mechanical properties. For advice on optimizing infill and structural strength, see resources on 3D printing infill patterns.

For a deeper dive into the fundamentals of additive manufacturing, including comparisons of different technologies, the comprehensive 3D printing guide from Hubs is a valuable external resource.

Frequently Asked Questions

What types of materials can be combined in a single 3D print?

The range of compatible materials depends on the printer and technology. Common combinations include different plastics (such as PLA and TPU), rigid and flexible resins, or even metals and ceramics in advanced systems. Always check material compatibility and printer specifications before starting a project.

How do I avoid weak bonds between different materials?

Achieving strong adhesion requires careful selection of materials with similar melting points or chemical properties. Adjusting print temperatures, using adhesives, or incorporating mechanical interlocks in the design can also improve bond strength. Reviewing expert tips on how to prevent warping in prints can help address common issues.

Is post-processing different for multimaterial prints?

Yes, post-processing can be more complex when working with multiple materials. Different sections of the print may require unique finishing techniques, such as sanding, painting, or dissolving support materials. For best results, consult guides on post processing 3D prints and related finishing methods.