The world of multi color 3D printing has expanded rapidly, allowing creators to produce objects with stunning, vivid hues and intricate patterns. Whether you’re a hobbyist, designer, or professional, the ability to print in multiple colors opens new doors for creativity and functionality. However, achieving sharp, vibrant results requires more than just loading a few different filaments into your printer.

This guide explores the essential techniques, hardware, and software considerations for producing striking, multi-hued 3D prints. From choosing the right printer and materials to optimizing your digital models, you’ll find practical advice to help you get the most out of your color printing projects.

For those interested in tackling more advanced shapes and surfaces, our article on printing complex geometries provides additional insights into overcoming design and print challenges.

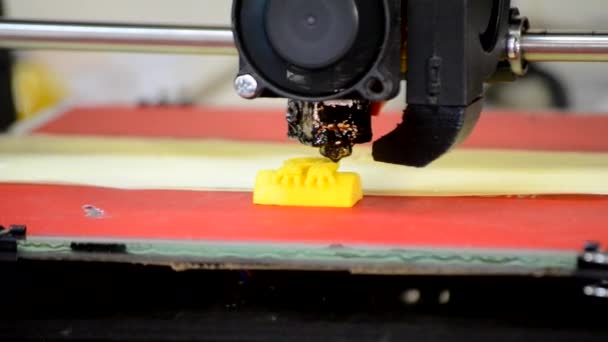

Understanding Multi-Color 3D Printing Technology

At its core, multi color 3D printing refers to the process of creating objects that feature two or more distinct colors within a single print job. This can be achieved through several methods, each with its own advantages and limitations:

- Dual Extrusion: Uses two print heads or nozzles, each loaded with a different filament color.

- Palette or Filament Mixing Devices: Devices like the Mosaic Palette splice and feed multiple filaments into one nozzle, allowing for more than two colors.

- Color-Changing Filaments: Some filaments change color based on temperature or light, though control is limited.

- Full-Color Inkjet 3D Printers: High-end machines that apply colored inks to each layer of a print, producing photorealistic results.

The method you choose will depend on your printer, budget, and the complexity of your intended designs.

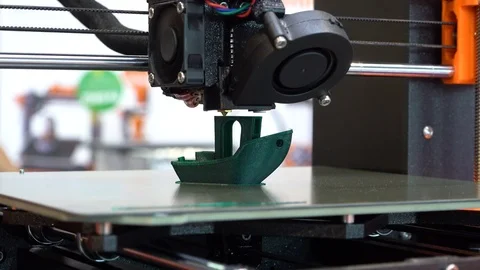

Choosing the Right Equipment for Multi-Hued Prints

Not all 3D printers are equipped to handle multi-color jobs out of the box. Here’s what to consider when selecting or upgrading your hardware:

- Dual or Multi-Extruder Printers: These allow you to print with two or more filaments simultaneously. Look for models with independent extruders for best results.

- Filament Splicing Accessories: Add-ons like the Palette can retrofit single-extruder printers to handle multiple colors by splicing filaments before they enter the hotend.

- Resin Printers with Color Capabilities: Some resin printers now offer color mixing or pigment injection for more vibrant resin prints.

For those ready to invest, you can buy a 3D printer or buy a resin 3D printer designed for advanced color work.

Preparing Your Models for Color Printing

The design stage is crucial for successful color prints. Here are some key steps to ensure your models are ready:

- Model Segmentation: Divide your model into separate parts or meshes, each corresponding to a different color. Most slicers recognize these as distinct color regions.

- File Formats: Use formats that support color and multi-part data, such as 3MF or OBJ. For more on this, see our resource on 3D printing file formats explained.

- Assigning Colors: In your CAD or modeling software, assign colors to each part or mesh. This information will be used by your slicer to map colors to extruders or filament changes.

- Design for Printability: Ensure that color transitions are clean and that overhangs or bridges are minimized for better results. For more tips, check out our article on how to design for 3D printing.

Optimizing Slicer Settings for Multi-Color Results

Slicer software is where your digital model is translated into printer instructions. When working with multiple colors, pay attention to these settings:

- Toolpath Assignment: Map each color or part to the correct extruder or filament input.

- Wipe and Purge Towers: Enable these features to prevent color contamination between changes. They help purge old filament and ensure crisp transitions.

- Prime Towers: For filament mixing, prime towers are essential to ensure the correct color is extruded at the right time.

- Layer Height and Print Speed: Finer layers and slower speeds can improve the sharpness of color boundaries.

Experimenting with these settings and running small test prints can help you dial in the best results for your specific setup.

Material Selection: Filaments and Resins for Color Printing

The choice of material plays a significant role in the vibrancy and durability of your finished prints. Here’s what to consider:

- PLA and PETG: These are the most common filaments for color printing, offering a wide range of shades and reliable performance.

- Specialty Color Filaments: Silk, matte, and color-changing filaments can add unique effects, but may require special handling.

- Resins: For resin printers, look for pigmented or mixable resins designed for color work.

- Storage and Handling: Keep filaments dry and away from sunlight to preserve color quality.

Always check compatibility between your chosen material and printer, especially when using advanced or specialty filaments.

Post-Processing for Enhanced Color and Finish

Even with the best printer and materials, some post-processing can elevate your results:

- Support Removal: Carefully remove supports to avoid damaging color boundaries.

- Sanding and Smoothing: Light sanding can even out transitions, while smoothing agents (like isopropyl alcohol for resin or acetone for ABS) can enhance surface finish.

- Protective Coatings: Clear sprays or varnishes can boost color vibrancy and protect against fading.

- Detail Painting: For small touch-ups, acrylic paints can be used to refine details or add highlights.

For more on preparing your models and avoiding common pitfalls, see our guide on 3D modeling tips for printing.

Software Tools and Workflow Tips

Leveraging the right software can simplify the process and improve your outcomes. Consider these workflow tips:

- CAD Software: Use programs that support color assignments and export compatible file types. Beginners may find our CAD for 3D printing beginners guide helpful.

- Slicer Compatibility: Ensure your slicer can handle multi-part models and assign colors to extruders or filament channels.

- Preview Features: Use preview tools to check color transitions and layer assignments before printing.

- Firmware Updates: Keep your printer’s firmware up to date for the latest color printing features and bug fixes.

For advanced workflows and integration with design software, resources like Autodesk’s 3D printing solutions offer powerful options for professionals.

Common Challenges and Troubleshooting

Even experienced users encounter obstacles when working with multiple colors. Here are some frequent issues and how to address them:

- Color Bleeding: Use purge towers and adjust retraction settings to minimize unwanted color mixing.

- Stringing and Oozing: Fine-tune temperature and retraction to reduce filament drips during color changes.

- Misaligned Layers: Regularly calibrate your printer and check for mechanical issues, especially with dual extruder setups.

- Software Compatibility: Make sure your slicer and firmware support the specific color printing features you need.

Patience and experimentation are key. Start with simple designs and gradually increase complexity as you gain confidence with your setup.

FAQ: Multi-Color 3D Printing

What types of printers are best for multi-color projects?

Printers with dual or multiple extruders are ideal, as they allow simultaneous use of different filaments. Single-extruder printers can also be adapted with filament splicing accessories. For the most advanced results, consider full-color inkjet 3D printers, though these are typically more expensive.

How do I prepare my 3D models for color printing?

Segment your model into separate parts or meshes, assign colors in your CAD software, and export in a compatible file format like 3MF or OBJ. Make sure your slicer recognizes these color assignments and maps them to the correct extruder or filament.

Can I use any filament for multi-color prints?

Most standard filaments like PLA and PETG work well, but for the best results, use high-quality, color-specific filaments. Specialty materials such as silk or color-changing filaments can add unique effects but may require special handling or printer settings.

What are some tips for achieving crisp color transitions?

Use purge or prime towers, adjust retraction and temperature settings, and slow down print speeds for sharper boundaries. Regular calibration and test prints can also help refine your results.