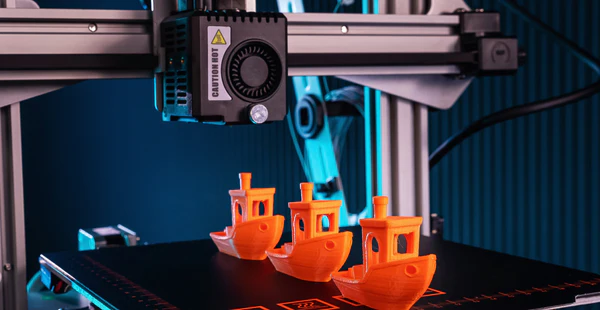

The demand for micro 3D printing techniques has surged as industries and hobbyists alike seek to produce intricate parts with exceptional precision. From medical devices and electronics to jewelry and research prototypes, achieving ultra-fine detail is now more accessible than ever. This guide explores the leading methods, materials, and best practices for producing miniature components with accuracy and consistency.

Whether you’re a professional engineer or an enthusiast aiming to push the boundaries of what’s possible with additive manufacturing, understanding these advanced approaches can help you unlock new creative and technical possibilities. For those looking to perfect their finished models, our resource on sanding and finishing 3D prints offers valuable post-processing insights.

Understanding the Basics of Microfabrication with 3D Printing

At its core, microfabrication using additive manufacturing involves producing components with features measured in microns. Unlike standard FDM or SLA printing, these processes require specialized equipment, materials, and design considerations. The main goal is to achieve high resolution and dimensional accuracy, often for parts that are smaller than a grain of rice.

The evolution of precision 3D printing has enabled the creation of complex geometries that traditional manufacturing methods struggle to replicate. This has opened doors in fields such as microfluidics, MEMS (micro-electromechanical systems), and biomedical engineering.

Key Micro 3D Printing Techniques for High-Resolution Results

Several advanced approaches have emerged for producing ultra-fine features. Each has its own strengths, limitations, and ideal applications.

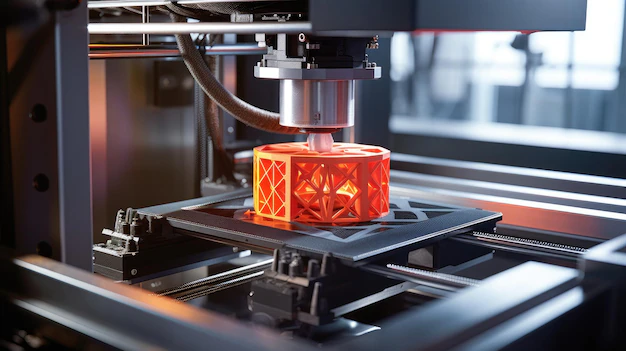

Resin-Based Methods: SLA, DLP, and Two-Photon Polymerization

Stereolithography (SLA) and Digital Light Processing (DLP) are popular for their ability to produce smooth surfaces and sharp details. These printers use a light source to cure liquid resin layer by layer, achieving resolutions down to 25 microns or better. For even finer features, two-photon polymerization uses a focused laser to solidify resin at the nanoscale, enabling the fabrication of structures with sub-micron accuracy.

Resin selection is crucial. Specialized formulations designed for micro applications offer lower viscosity and higher reactivity, which help minimize feature distortion and improve print fidelity.

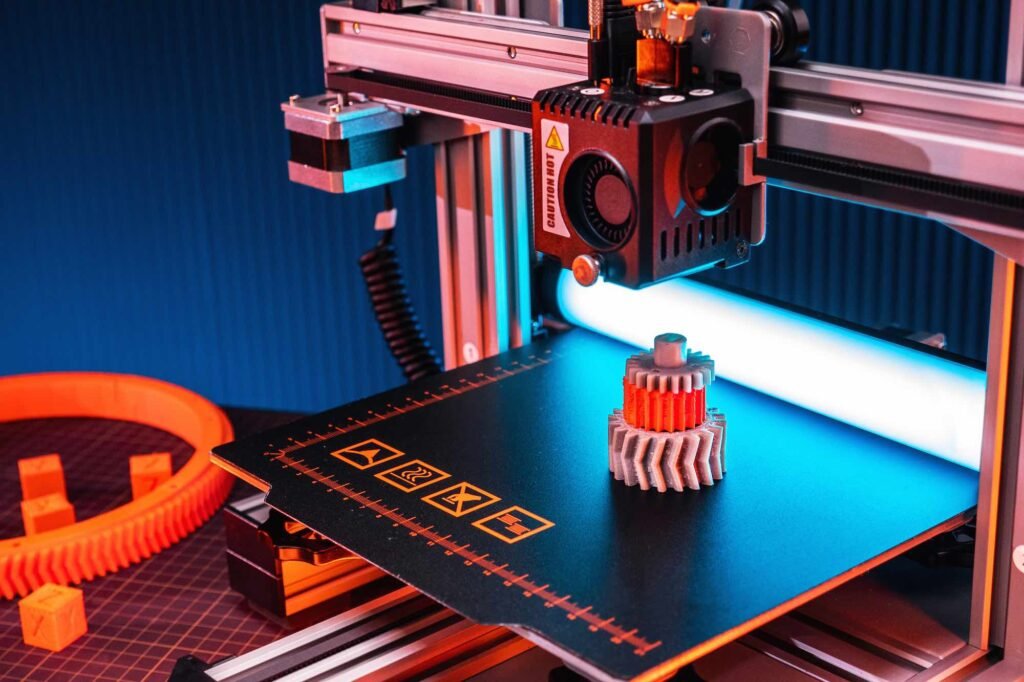

Micro-Extrusion and Fused Deposition Modeling (FDM) for Small Parts

While traditional FDM is not typically associated with micro-scale work, recent advances in nozzle design and filament control have made it possible to print features as small as 100 microns. Micro-extrusion systems use ultra-fine nozzles and precisely tuned extrusion parameters to lay down thin lines of thermoplastic, making them suitable for rapid prototyping of small mechanical parts.

Inkjet and Binder Jetting for Micro-Scale Prototyping

Inkjet-based systems deposit tiny droplets of material or binder onto a substrate, building up complex shapes with fine resolution. These techniques are especially useful for producing microfluidic devices, electronics, and biomedical scaffolds. The layer thickness and droplet size can be controlled to achieve features as small as 20 microns.

Binder jetting also allows for multi-material printing, enabling the integration of conductive, structural, and support materials in a single build.

Optimizing Design for Ultra-Fine 3D Printed Features

Designing for micro-scale additive manufacturing requires a different mindset than standard 3D printing. Here are some key considerations:

- Wall Thickness: Keep walls as thin as the printer and material allow, but ensure structural integrity.

- Support Structures: Plan for easy removal without damaging delicate features.

- Orientation: Position parts to minimize overhangs and maximize detail where needed.

- Tolerance: Account for printer and material limitations in your CAD models.

For more on how to achieve smooth, professional results after printing, see our guide to post processing 3D prints.

Materials for Micro 3D Printing: Choosing the Right Resin or Filament

The choice of material can make or break the success of your micro-scale project. Here are some commonly used options:

- Photopolymer Resins: Engineered for high resolution, these are ideal for SLA, DLP, and two-photon systems.

- Engineering Thermoplastics: Used in micro-extrusion, materials like PEEK and polycarbonate offer strength and heat resistance.

- Conductive Inks: For inkjet and binder jetting, these enable the creation of micro-electronic components.

Always consult your printer’s specifications and test with small batches before committing to a full production run.

Best Practices for Achieving Ultra-Fine Details

Even with the right equipment and materials, achieving consistent results requires careful attention to process parameters. Here are some proven strategies:

- Calibrate Regularly: Ensure your printer is precisely tuned for layer height, exposure time, and nozzle temperature.

- Maintain a Clean Environment: Dust and debris can ruin micro-scale prints. Work in a controlled, clean space.

- Monitor Print Progress: Use magnification or cameras to inspect layers as they’re built, catching errors early.

- Refine Post-Processing: Delicate sanding, polishing, or chemical smoothing can enhance surface quality. For tips, our article on painting 3D printed models covers finishing techniques suitable for small parts.

Applications and Industry Use Cases

The ability to fabricate tiny, precise components has revolutionized several sectors:

- Medical Devices: Custom micro-needles, stents, and surgical tools.

- Electronics: Micro-connectors, circuit boards, and sensor housings.

- Research: Microfluidic chips for chemical and biological analysis.

- Jewelry and Art: Highly detailed miniatures and custom pieces.

For a broader look at how additive manufacturing is transforming industries, see this comprehensive overview of 3D printing technology.

Common Challenges and Troubleshooting Tips

Working at the micro scale introduces unique hurdles. Here’s how to address some of the most frequent issues:

- Layer Shifting: Ensure your printer’s mechanics are tight and the build platform is stable.

- Incomplete Curing: Adjust exposure times and verify resin compatibility for your light source.

- Warping and Shrinkage: Use temperature-controlled environments and select materials with low shrinkage rates. For more advice, check out our article on how to prevent warping in prints.

- Support Removal Damage: Design supports that are easy to detach and use gentle post-processing methods.

FAQ: Micro-Scale 3D Printing Insights

What is the smallest feature size achievable with current micro 3D printing methods?

With advanced resin-based systems like two-photon polymerization, it’s possible to achieve features below 1 micron. More common desktop SLA and DLP printers can reliably produce details down to 25–50 microns, while micro-extrusion FDM systems typically reach around 100 microns.

Which materials are best for printing tiny, precise components?

Photopolymer resins specifically formulated for high resolution are ideal for most micro-scale applications. For FDM, engineering-grade thermoplastics such as PEEK or polycarbonate provide strength and heat resistance. For electronic or biomedical uses, specialty conductive or biocompatible materials may be required.

How can I improve the surface finish of micro 3D printed parts?

Fine-tuning print parameters, using high-quality materials, and employing careful post-processing techniques like sanding, polishing, or chemical smoothing can significantly enhance surface quality. For step-by-step guidance, see our detailed article on post processing 3D prints.

Are there specific design guidelines for micro-scale additive manufacturing?

Yes. Maintain minimum wall thicknesses as recommended by your printer manufacturer, avoid unsupported overhangs, and consider the removal of supports during post-processing. Always prototype and test before scaling up production.

Mastering micro 3D printing techniques requires a blend of the right technology, material knowledge, and attention to detail. By following these best practices and leveraging the latest advancements, you can consistently produce parts with remarkable precision and complexity.