Metal additive manufacturing has transformed the way industries approach design, prototyping, and production. By enabling the creation of complex metal parts directly from digital files, this technology offers unprecedented flexibility and efficiency. As businesses seek faster turnaround times and greater design freedom, understanding the core techniques and practical applications of this process is essential.

This guide explores the primary methods, advantages, and real-world uses of metal-based 3D printing. Whether you’re new to the field or looking to deepen your knowledge, you’ll find actionable insights and resources to help you navigate this rapidly evolving landscape. For those interested in refining their finished parts, techniques such as sanding and finishing 3D prints can further enhance the quality and performance of your components.

Understanding Metal 3D Printing Processes

At its core, metal additive manufacturing involves building objects layer by layer from metal powders or wires. Unlike traditional subtractive methods, which remove material from a solid block, additive techniques minimize waste and allow for intricate geometries. Several processes are widely used in industry, each with unique benefits and considerations.

Powder Bed Fusion: Precision and Versatility

One of the most established approaches is powder bed fusion (PBF). In this process, a thin layer of metal powder is spread across a build platform. A high-powered energy source, such as a laser or electron beam, selectively fuses the powder according to the digital design. The platform then lowers, and a new layer of powder is applied, repeating the cycle until the part is complete.

Common variants of PBF include:

- Selective Laser Melting (SLM): Uses a laser to fully melt metal powder, producing dense and strong parts.

- Electron Beam Melting (EBM): Employs an electron beam in a vacuum, ideal for titanium alloys and aerospace components.

- Direct Metal Laser Sintering (DMLS): Similar to SLM but may not fully melt the powder, resulting in slightly different material properties.

Directed Energy Deposition: Repair and Large-Scale Fabrication

Directed energy deposition (DED) is another key technique. Here, metal powder or wire is fed through a nozzle while a focused energy source (laser, electron beam, or plasma arc) melts the material as it is deposited. DED is especially useful for repairing existing parts, adding features to pre-formed components, or creating large structures that exceed the build volumes of powder bed systems.

Binder Jetting and Other Emerging Methods

Binder jetting represents a different approach. Instead of melting the metal, a liquid binder is selectively deposited onto a bed of metal powder to create a “green” part. This part is then sintered in a furnace to achieve its final strength. Binder jetting is valued for its speed and scalability, making it attractive for high-volume production of small to medium-sized parts.

Other emerging technologies, such as metal extrusion and cold spray, continue to expand the possibilities for additive manufacturing with metals. Each method offers distinct trade-offs in terms of speed, cost, material compatibility, and mechanical properties.

Advantages of Metal-Based 3D Printing

The adoption of metal additive manufacturing brings several significant benefits to manufacturers and designers:

- Design Freedom: Complex internal channels, lattice structures, and lightweight geometries are possible without the constraints of traditional tooling.

- Rapid Prototyping: Engineers can quickly iterate on designs, reducing development cycles and accelerating innovation.

- Material Efficiency: Additive processes use only the material needed for the part, minimizing scrap and lowering costs.

- On-Demand Production: Parts can be produced as needed, reducing inventory requirements and enabling localized manufacturing.

- Customization: Tailored components for specific applications or patients (in medical fields) can be created with ease.

These advantages are particularly valuable in industries where performance, weight, and speed are critical. For example, aerospace and automotive sectors leverage additive methods to produce lighter, stronger parts that would be difficult or impossible to machine conventionally.

Industrial Applications and Real-World Impact

The impact of metal-based 3D printing is evident across a range of industries. Here are some of the most prominent applications:

Aerospace and Defense

Aircraft manufacturers use additive technology to produce lightweight brackets, engine components, and even entire structural assemblies. The ability to consolidate multiple parts into a single, optimized component reduces weight and assembly time, improving fuel efficiency and reliability.

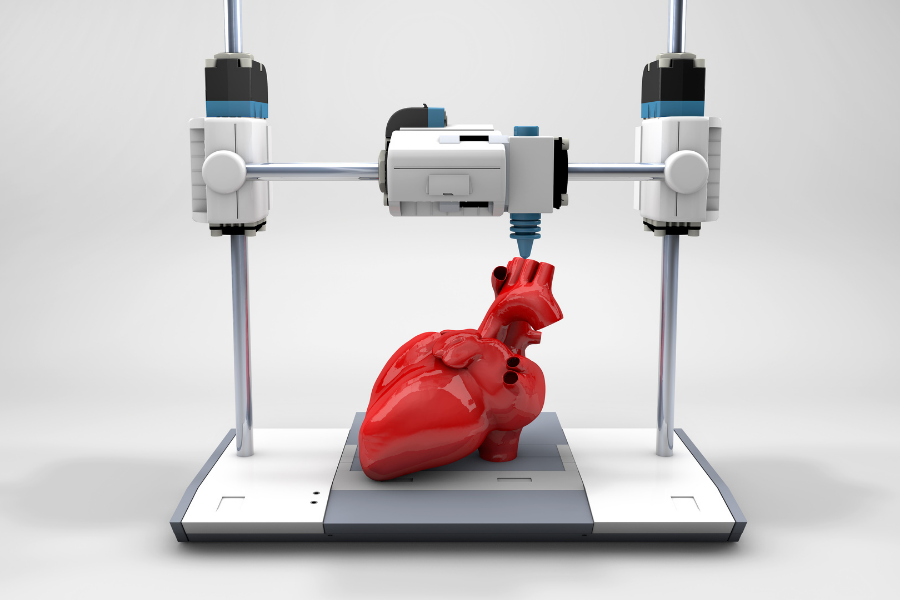

Medical and Dental Fields

Custom implants, prosthetics, and surgical tools are increasingly produced using metal 3D printing. Patient-specific devices can be designed from medical scans, ensuring a perfect fit and faster recovery times. Dental labs also benefit from the precision and repeatability of additive processes for crowns, bridges, and orthodontic devices.

Automotive and Tooling

Car manufacturers and suppliers use additive manufacturing for rapid prototyping, lightweight structural parts, and specialized tooling. The ability to quickly produce jigs, fixtures, and end-use components streamlines production and supports innovation in electric vehicles and motorsports.

Energy and Industrial Equipment

Turbine blades, heat exchangers, and oil & gas components are being reimagined with the help of additive methods. Improved cooling channels and optimized geometries enhance performance and extend the lifespan of critical equipment.

Key Considerations for Adopting Metal 3D Printing

While the benefits are clear, there are important factors to consider before integrating metal-based additive manufacturing into your workflow:

- Material Selection: Not all metals are suitable for every process. Common choices include stainless steel, titanium, aluminum, and cobalt-chrome alloys.

- Post-Processing: Most parts require additional steps such as support removal, heat treatment, or surface finishing. For more on this, see our guide on post processing 3D prints.

- Cost and Scalability: Initial investment in equipment and training can be significant. However, costs may be offset by reduced waste and faster time-to-market.

- Quality Assurance: Ensuring consistent part quality requires robust monitoring and inspection protocols, especially for critical applications.

For those exploring equipment options, a range of industrial 3D printers are available, each suited to different materials and production volumes.

Best Practices for Success

To maximize the advantages of metal-based 3D printing, consider these practical tips:

- Collaborate with experienced designers who understand the unique constraints and opportunities of additive processes.

- Invest in simulation and design optimization tools to reduce trial and error.

- Plan for post-processing from the outset, including finishing, machining, and inspection.

- Stay informed about new materials and process improvements to maintain a competitive edge.

- Address potential issues such as warping early in the design phase. For more insights, review our article on how to prevent warping in prints.

Frequently Asked Questions

What metals can be used in additive manufacturing?

A wide variety of metals are compatible with additive processes, including stainless steel, titanium, aluminum, nickel-based superalloys, and cobalt-chrome. The choice depends on the specific application, required properties, and the printing technology used.

How does metal 3D printing compare to traditional manufacturing?

Additive methods offer greater design flexibility, reduced material waste, and faster prototyping. However, traditional manufacturing may still be more cost-effective for high-volume, simple parts. The best approach often combines both methods, leveraging the strengths of each.

What post-processing steps are needed for metal 3D printed parts?

Most metal parts require support removal, heat treatment to relieve stresses, and surface finishing such as machining or polishing. For detailed techniques, see our guide on sanding and finishing 3D prints.

Is metal additive manufacturing suitable for end-use production?

Yes, many industries use metal-based 3D printing for both prototypes and final products, especially when complex geometries or customization are needed. Quality assurance and post-processing are key to ensuring parts meet performance requirements.

As metal additive manufacturing continues to advance, its role in shaping the future of industry will only grow. By understanding the available techniques, practical benefits, and best practices, businesses can unlock new possibilities in design and production.