The metal 3D printing process has transformed manufacturing by enabling the creation of complex, custom metal parts directly from digital designs. This technology, also known as additive manufacturing for metals, is used across industries such as aerospace, automotive, healthcare, and tooling. Unlike traditional subtractive methods, which remove material from a solid block, metal additive manufacturing builds objects layer by layer, resulting in less waste and greater design freedom.

In this guide, you’ll learn how metal additive manufacturing works, the main technologies involved, and the practical considerations for adopting it in production or prototyping. If you’re interested in the broader context, you might want to explore the history of 3D printing to see how these innovations have evolved.

Understanding Metal Additive Manufacturing

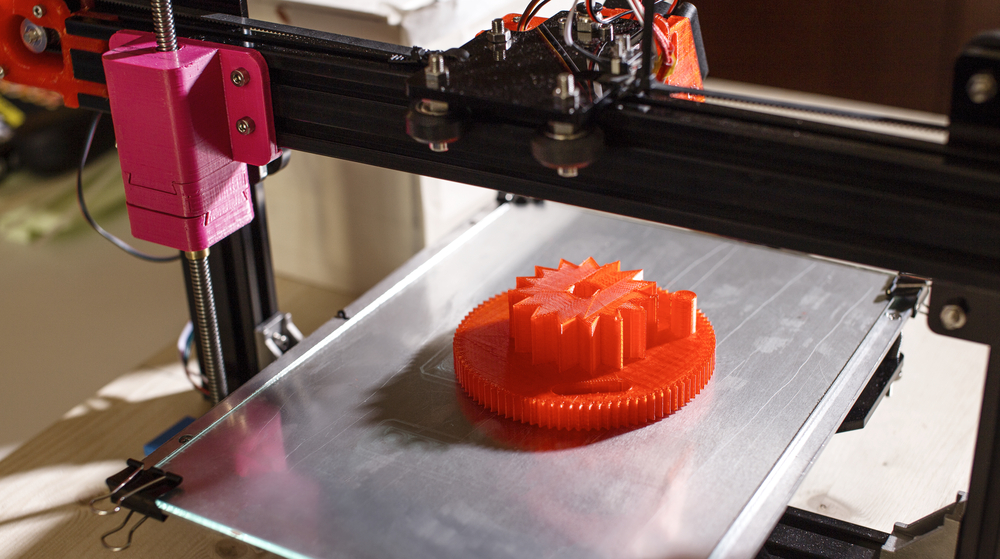

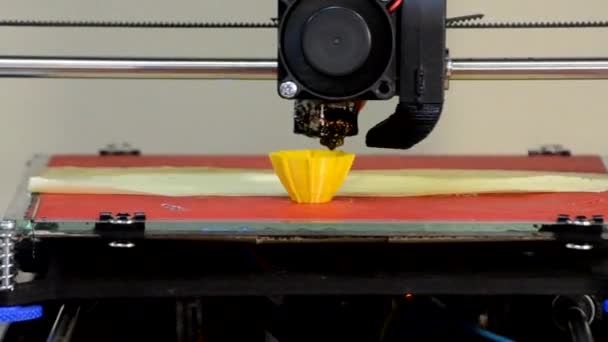

At its core, the metal 3D printing process involves using a digital model to guide the deposition or fusion of metal material, layer by layer, until a finished part is formed. This approach allows for the fabrication of intricate geometries that are difficult or impossible to achieve with conventional manufacturing.

The process starts with a 3D CAD file, which is sliced into thin cross-sections. The printer then follows these slices to build the object from the ground up. The choice of metal powder or wire, the energy source, and the specific method all influence the properties and applications of the final product.

Key Technologies in Metal 3D Printing

Several distinct technologies are used in metal additive manufacturing. Each has its own advantages and ideal applications. Here are the most common methods:

- Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS): These techniques use a high-powered laser to fuse metal powder particles together. SLM fully melts the powder, while DMLS sinters it. Both are popular for producing strong, dense parts.

- Electron Beam Melting (EBM): EBM employs an electron beam instead of a laser to melt metal powder. It operates in a vacuum and is often used for titanium alloys in aerospace and medical implants.

- Binder Jetting: This method deposits a liquid binder onto a bed of metal powder, layer by layer. The resulting “green” part is then sintered in a furnace to achieve its final strength.

- Directed Energy Deposition (DED): DED uses a focused energy source (laser or electron beam) to melt metal as it is deposited, often from a nozzle. It’s suitable for repairing or adding features to existing parts.

For a deeper dive into the different approaches, see the overview of types of 3D printing technologies.

Step-by-Step Breakdown of the Metal Printing Workflow

The journey from digital design to finished metal part involves several key steps. Understanding each phase helps ensure successful results and highlights where quality control is most critical.

- Design and Preparation: The process begins with a 3D model, typically created in CAD software. The model is analyzed for printability, and support structures are added if needed. The file is then sliced into layers.

- Material Loading: The chosen metal powder or wire is loaded into the printer. Material quality and particle size distribution are crucial for consistent results.

- Printing: The machine builds the part layer by layer. For powder-bed systems, a thin layer of powder is spread, then selectively fused by the energy source. This repeats until the object is complete.

- Post-Processing: Once printing is finished, parts often require removal of supports, heat treatment, surface finishing, or machining to achieve the desired properties and tolerances.

- Quality Inspection: Final inspection ensures the part meets specifications. Non-destructive testing, dimensional checks, and material analysis are common at this stage.

Materials Used in Metal Additive Manufacturing

A wide range of metals and alloys can be processed using these techniques. Some of the most common materials include:

- Stainless steels – valued for corrosion resistance and strength

- Titanium alloys – lightweight and biocompatible, ideal for aerospace and medical

- Aluminum alloys – prized for their low weight and good mechanical properties

- Nickel superalloys – used in high-temperature environments such as turbines

- Tool steels – suitable for molds, dies, and high-wear applications

Material selection depends on the intended use, required mechanical properties, and the specific printing technology. For more on the advantages of this approach, see the benefits of 3D printing in manufacturing.

Advantages and Challenges of Metal Additive Manufacturing

The metal 3D printing process offers several compelling benefits:

- Design freedom: Create complex geometries, internal channels, and lightweight structures not possible with traditional methods.

- Material efficiency: Additive manufacturing minimizes waste by only using material where needed.

- Rapid prototyping and production: Quickly iterate designs and produce functional metal parts on demand.

- Customization: Easily tailor parts for specific applications or users, such as patient-specific implants.

However, there are also challenges to consider:

- High equipment and material costs compared to some conventional processes

- Need for specialized design skills and software

- Post-processing requirements can be significant

- Size limitations depending on the printer

- Potential for defects if process parameters are not carefully controlled

For a look at where this technology is heading, check out the future of 3D printing and how it is shaping manufacturing and design.

Applications of Metal Additive Manufacturing

Metal additive manufacturing is used in a variety of sectors:

- Aerospace: Lightweight, strong parts for aircraft and spacecraft, including brackets, housings, and engine components.

- Medical: Custom implants, surgical tools, and dental devices tailored to individual patients.

- Automotive: Prototyping, tooling, and production of high-performance components.

- Tooling and industrial: Rapid production of molds, dies, and replacement parts.

- Energy: Components for turbines, oil and gas, and power generation.

The ability to produce complex, high-performance parts quickly and efficiently is driving adoption in these industries. For more on how this compares to other methods, see the discussion on FDM vs SLA printing.

Best Practices and Considerations

To get the most out of metal additive manufacturing, consider the following best practices:

- Design for Additive: Optimize your models for the process, taking advantage of unique design freedoms and minimizing support structures.

- Material Selection: Choose the right alloy for your application, balancing performance, cost, and printability.

- Process Control: Monitor key parameters such as layer thickness, energy input, and environmental conditions to ensure quality.

- Post-Processing: Plan for finishing steps like heat treatment, machining, and inspection.

- Training: Invest in training for designers, operators, and quality control staff to maximize success.

For a more technical explanation of how 3D printers work, including both plastic and metal systems, see this detailed guide to 3D printing technology.

Frequently Asked Questions

What metals can be used in 3D printing?

Common metals include stainless steel, titanium, aluminum, nickel-based superalloys, and tool steels. The choice depends on the application and the specific printing technology.

How strong are metal 3D printed parts?

Parts produced using metal additive manufacturing can match or exceed the strength of those made with traditional methods, especially when post-processing steps like heat treatment are applied. Mechanical properties depend on the material, process, and design.

Is metal additive manufacturing suitable for mass production?

While ideal for prototyping, custom, and low-volume production, advances in speed and automation are making it increasingly viable for larger-scale manufacturing, especially for complex or high-value parts.