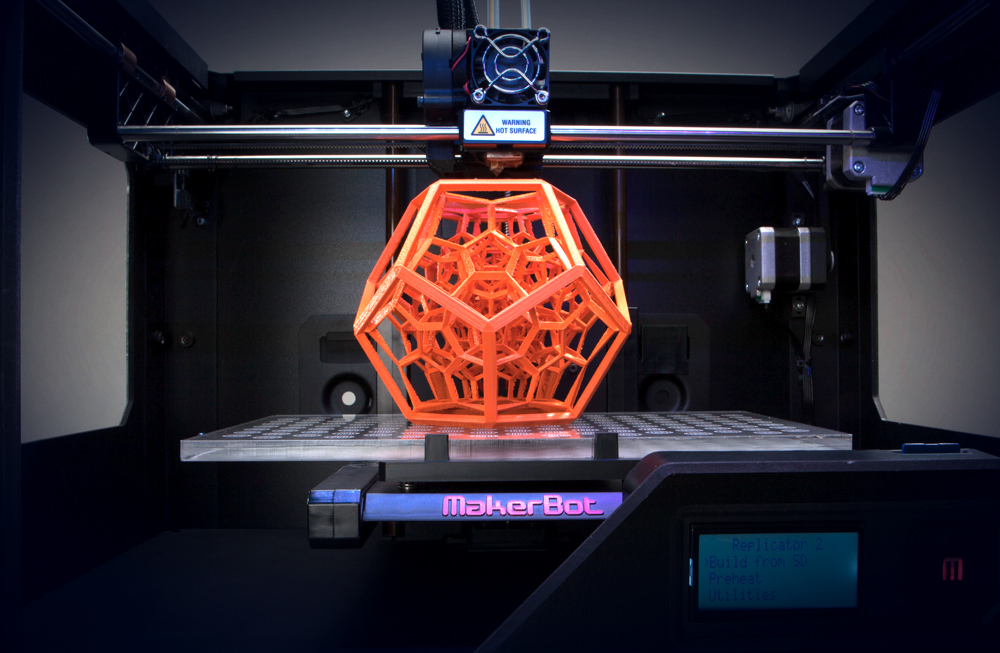

The intersection of machine learning in additive manufacturing is transforming the way 3D-printed parts are designed, produced, and optimized. As 3D printing technologies mature, manufacturers and engineers are leveraging data-driven algorithms to improve print quality, reduce waste, and accelerate innovation. Understanding how artificial intelligence and data analytics can be applied to 3D printing processes is essential for anyone aiming to stay competitive in this rapidly evolving field.

This guide explores the practical applications of AI in 3D printing, from predictive maintenance to real-time error correction. Along the way, you’ll discover how integrating smart algorithms can help you achieve more consistent results, streamline workflows, and unlock new possibilities in design and production. For those interested in mastering advanced fabrication, learning about printing complex geometries is also a valuable step.

How Artificial Intelligence Enhances 3D Printing

The integration of machine learning in additive manufacturing brings a new level of intelligence to the 3D printing process. By analyzing vast amounts of data from sensors, cameras, and print logs, AI systems can identify patterns that are invisible to the human eye. This enables manufacturers to detect anomalies, predict failures, and optimize print parameters in real time.

For example, machine learning algorithms can automatically adjust temperature, speed, and layer thickness based on feedback from previous prints. This adaptive approach minimizes defects and ensures higher consistency across batches. Additionally, AI-driven monitoring tools can alert operators to potential issues before they escalate, reducing downtime and material waste.

Key Benefits of Data-Driven Optimization in 3D Printing

Leveraging AI in 3D printing delivers several tangible advantages:

- Improved Print Quality: Algorithms can fine-tune settings to achieve optimal surface finish and dimensional accuracy.

- Reduced Material Waste: Predictive analytics help minimize failed prints and unnecessary support structures.

- Faster Prototyping: Automated parameter optimization shortens iteration cycles, speeding up product development.

- Enhanced Process Control: Real-time monitoring enables immediate corrections, reducing the risk of costly errors.

- Predictive Maintenance: AI can forecast equipment failures, allowing for proactive servicing and less unplanned downtime.

Applications of Machine Learning in Additive Manufacturing

The use of machine learning in additive manufacturing spans a wide range of applications. Here are some of the most impactful areas:

1. Automated Defect Detection

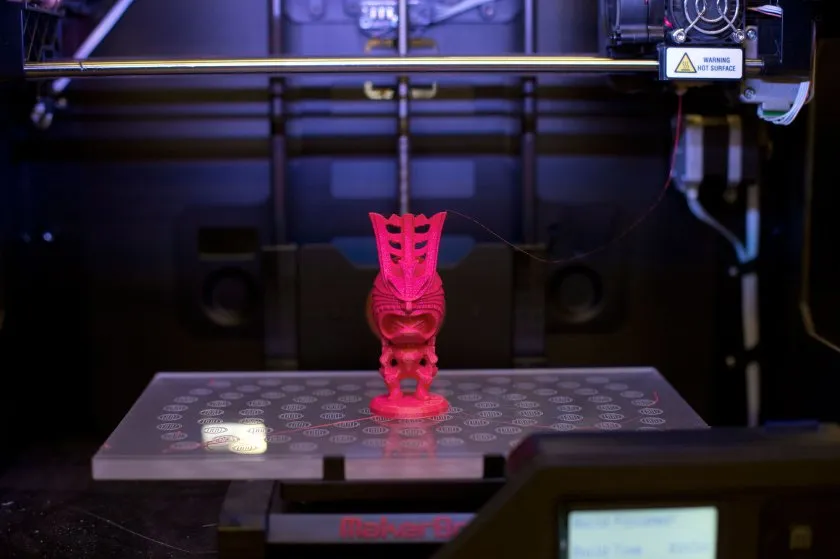

Computer vision and deep learning models analyze images of prints as they are being produced. These systems can spot defects such as layer shifts, warping, or incomplete infill, often before they become visible to the naked eye. Early detection allows for immediate intervention, saving time and resources.

2. Adaptive Slicing and Toolpath Generation

Traditional slicing software uses fixed rules to convert 3D models into printable layers. With AI, slicing becomes dynamic. Algorithms can analyze the geometry and material properties to generate customized toolpaths, improving structural integrity and reducing print time. For more on preparing digital models, see 3D printing file formats explained.

3. Process Parameter Optimization

AI systems can learn from historical print data to recommend the best settings for new jobs. By considering variables like material type, geometry, and printer model, these tools help users avoid common pitfalls. This is especially useful for those new to the field—resources like how to design for 3D printing offer further guidance on model preparation.

Implementing AI in Your 3D Printing Workflow

Adopting intelligent algorithms in additive manufacturing doesn’t have to be overwhelming. Here’s a step-by-step approach to get started:

- Collect Data: Begin by gathering print logs, sensor readings, and images from your existing jobs. The more data you have, the better your AI models will perform.

- Choose the Right Tools: Select software platforms or plugins that offer AI-powered features, such as automated defect detection or parameter optimization.

- Integrate and Test: Implement the chosen solutions into your workflow. Run test prints and compare results to your previous methods.

- Iterate: Use feedback from the AI system to refine your process. Over time, the algorithms will become more accurate and valuable.

- Stay Informed: The field is evolving rapidly. Keep up with the latest developments by exploring resources like in-depth guides to 3D printing mechanisms and examples.

Challenges and Considerations for AI-Driven 3D Printing

While the benefits are clear, integrating AI into additive manufacturing comes with its own set of challenges:

- Data Quality: Inaccurate or incomplete data can lead to poor model performance. Consistent data collection is essential.

- Integration Complexity: Merging AI tools with legacy systems may require technical expertise and process adjustments.

- Cost: Advanced software and hardware can involve upfront investment, though long-term savings often justify the expense.

- Skill Gaps: Teams may need training to fully leverage AI-powered solutions. Resources like 3D modeling tips for printing can help bridge knowledge gaps.

Future Trends in Smart Additive Manufacturing

The future of 3D printing will be shaped by increasingly sophisticated AI algorithms. Some emerging trends include:

- Closed-Loop Control: Systems that automatically adjust parameters mid-print based on sensor feedback.

- Generative Design: AI-driven software that creates optimized structures beyond what human designers might conceive.

- Material Innovation: Machine learning models that predict the properties of new materials before they are printed.

- Cloud-Based Collaboration: Centralized platforms where print data is shared and analyzed across global teams.

As these technologies mature, the synergy between AI and 3D printing will continue to unlock new levels of efficiency and creativity. Beginners can benefit from foundational resources like CAD for 3D printing beginners to build a strong base before diving into more advanced AI-driven workflows.

Frequently Asked Questions

How does machine learning improve the quality of 3D prints?

By analyzing data from previous prints and real-time sensors, AI algorithms can automatically adjust print parameters to minimize defects and ensure consistent results. This leads to better surface finish, dimensional accuracy, and fewer failed prints.

What types of data are used by AI in additive manufacturing?

Data sources include print logs, sensor readings (such as temperature and humidity), images from cameras monitoring the build process, and material properties. The more comprehensive the data, the more effective the AI models become.

Is it difficult to implement AI in a small-scale 3D printing operation?

While there is an initial learning curve, many software solutions now offer user-friendly interfaces and plug-and-play features. Starting with basic monitoring and gradually integrating more advanced tools is a practical approach for small businesses and hobbyists.