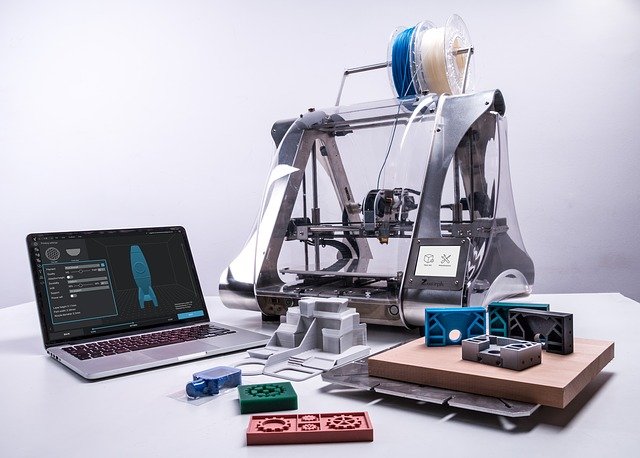

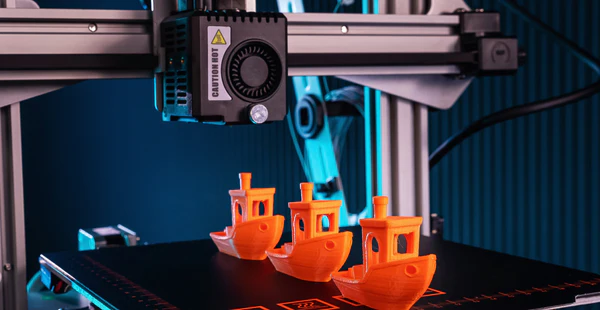

Liquid resin 3D printing has become a cornerstone of modern additive manufacturing, offering unmatched detail and surface quality for hobbyists, professionals, and industrial designers alike. This process, also known as vat photopolymerization, uses light to cure liquid resin layer by layer, resulting in highly accurate and intricate parts. Whether you’re new to the technology or looking to refine your workflow, understanding the methods, materials, and best practices is essential for achieving optimal results.

In this article, we’ll break down the core techniques, explore the range of resins available, and provide actionable advice for successful prints. We’ll also highlight essential post-processing steps and link to further resources, such as sanding and finishing 3D prints, to help you achieve professional-quality outcomes.

Understanding Vat Photopolymerization Methods

There are several main approaches to liquid resin 3D printing, each with its own advantages and ideal use cases. The most popular technologies are:

- SLA (Stereolithography): Utilizes a laser to selectively cure resin. Known for high accuracy and smooth finishes, SLA is widely used for prototyping, dental models, and jewelry.

- DLP (Digital Light Processing): Employs a digital projector to cure entire layers at once, resulting in faster print times. DLP is favored for its speed and ability to produce fine details.

- LCD (Masked Stereolithography): Uses an LCD screen to mask UV light, curing resin layer by layer. LCD printers are often more affordable and accessible for home users, with excellent resolution.

All these methods rely on a vat of liquid photopolymer resin and a light source to solidify the material. The choice between them depends on your budget, desired print speed, and the level of detail required.

Choosing the Right Resin for Your Project

The selection of resin is a critical factor in achieving the desired properties and appearance of your prints. The most common types include:

- Standard Resins: These are general-purpose materials that offer a balance of strength, detail, and ease of use. They are ideal for prototypes and visual models.

- Tough and Durable Resins: Designed for functional parts, these resins provide enhanced impact resistance and flexibility.

- Flexible Resins: Suitable for parts that need to bend or compress, such as gaskets or wearable devices.

- Castable Resins: Used for investment casting, especially in jewelry and dental applications, these resins burn out cleanly without leaving residue.

- High-Temperature Resins: Engineered for applications requiring thermal stability, such as molds or engineering prototypes.

- Specialty Resins: These include dental, biocompatible, or transparent variants tailored for specific industries.

When selecting a resin, consider the mechanical properties, color options, and post-processing requirements. Manufacturers provide detailed datasheets to help users match the right material to their application.

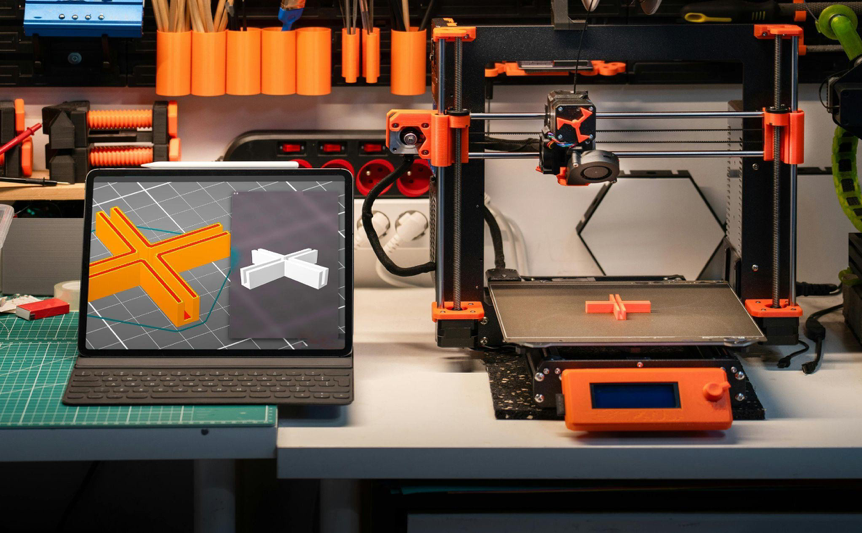

Essential Techniques for Successful Resin Printing

Mastering the process of liquid resin 3D printing involves more than just loading a file and pressing start. Here are some key practices to ensure high-quality results:

- Level the Build Platform: Proper leveling is crucial for adhesion and print accuracy. Follow your printer’s instructions to calibrate the platform before each print.

- Optimize Print Settings: Adjust layer height, exposure time, and lift speeds according to your resin and model requirements. Many manufacturers provide recommended settings for their materials.

- Maintain Cleanliness: Keep the resin vat, build platform, and surrounding area free of dust and cured resin debris. Contaminants can cause print failures or defects.

- Monitor Resin Levels: Ensure there is enough resin in the vat to complete the print. Running out mid-print can damage both the model and the printer.

- Use Supports Wisely: Most models require support structures to prevent sagging or detachment during printing. Place supports strategically to minimize marks and ease removal.

For more advanced tips on achieving smooth surfaces and professional finishes, see our guide on post processing 3D prints.

Post-Processing: Cleaning and Curing Your Prints

After printing, parts produced with vat photopolymerization require careful post-processing to reach their final form. The typical workflow includes:

- Rinsing: Remove uncured resin by washing the print in isopropyl alcohol (IPA) or a dedicated cleaning solution. Use gloves to protect your skin.

- Support Removal: Carefully detach supports using flush cutters or tweezers. Take your time to avoid damaging delicate features.

- Final Curing: Expose the print to UV light (using a curing station or sunlight) to fully harden the material and achieve optimal mechanical properties.

- Finishing Touches: Sand, polish, or paint your model as desired. For a detailed breakdown of finishing techniques, explore our article on painting 3D printed models.

Common Challenges and Troubleshooting

Even experienced users encounter issues with resin-based 3D printing. Here are some frequent problems and how to address them:

- Poor Adhesion: If prints don’t stick to the build plate, re-level the platform and clean it thoroughly. Increasing the bottom layer exposure time can also help.

- Layer Separation or Warping: Ensure the printer is in a stable environment, and avoid drafts or temperature fluctuations. For more on this topic, see our advice on how to prevent warping in prints.

- Print Artifacts: Lines, blobs, or holes may result from dirty resin, incorrect exposure settings, or an unclean FEP film. Regular maintenance is key.

- Cloudy or Brittle Prints: Over-curing or using expired resin can cause these issues. Always store resin in a cool, dark place and check expiration dates.

Expanding Your Knowledge and Resources

As the field of liquid resin 3D printing evolves, staying informed is crucial. For a foundational overview of additive manufacturing, visit this comprehensive guide to 3D printing technologies. Exploring topics like 3D printing infill patterns and advanced finishing techniques can further enhance your results.

Frequently Asked Questions

What safety precautions should I take when working with liquid resin?

Always wear gloves and work in a well-ventilated area. Avoid direct skin contact with uncured resin, and use safety glasses when handling chemicals or cleaning prints. Dispose of waste resin according to local regulations.

How do I store unused resin between prints?

Store unused resin in its original, sealed container away from sunlight and heat. If you need to leave resin in the vat, cover it to prevent dust and light exposure, and stir gently before the next use.

Can I reuse leftover resin from the vat?

Yes, but always filter the resin to remove cured particles before pouring it back into the bottle. Contaminated resin can cause print failures and damage your equipment.