The world of manufacturing has undergone a remarkable transformation with the rise of additive manufacturing. Often referred to as 3D printing, this innovative approach builds objects layer by layer from digital designs, offering new possibilities for design, prototyping, and production. Unlike traditional subtractive methods that carve or cut away material, additive techniques create less waste and enable more complex geometries. This guide explores the fundamentals of this technology, its key processes, and its wide-ranging applications across industries.

For those interested in a step-by-step breakdown of the process, our how 3D printing works article provides a practical overview for beginners.

Understanding the Fundamentals of Additive Manufacturing

At its core, additive manufacturing is a process that constructs objects by depositing material in successive layers, guided by a digital model. This approach contrasts with conventional manufacturing, where material is removed from a solid block or shaped using molds. The digital workflow starts with a 3D model, often created using computer-aided design (CAD) software. The model is then sliced into thin horizontal layers, and the printer follows these instructions to build the object from the bottom up.

The flexibility of this method allows for rapid prototyping, on-demand production, and the creation of intricate structures that would be difficult or impossible to achieve using traditional techniques. As a result, it has become a valuable tool for engineers, designers, and manufacturers seeking to innovate and reduce time to market.

Key Technologies in Modern 3D Printing

Several distinct technologies fall under the umbrella of additive manufacturing. Each has unique advantages and is suited to different applications. The most common methods include:

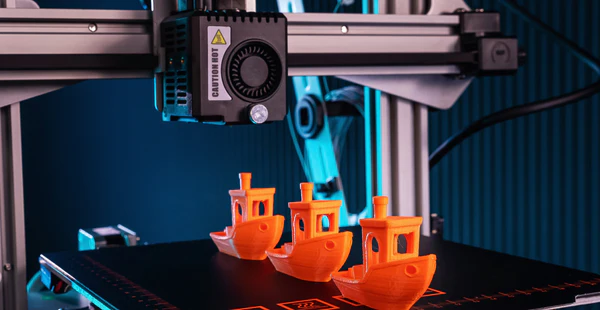

- Fused Deposition Modeling (FDM): This widely used technique extrudes melted thermoplastic filament through a heated nozzle, building up objects layer by layer. FDM is popular for its affordability and accessibility, making it a favorite for hobbyists and prototyping.

- Stereolithography (SLA): SLA printers use a laser or projector to cure liquid resin into solid plastic, producing parts with high resolution and smooth surfaces. This method is ideal for detailed prototypes and models.

- Selective Laser Sintering (SLS): SLS employs a laser to fuse powdered materials, such as nylon or metal, into solid structures. It enables the creation of durable, functional parts without the need for support structures.

- Direct Metal Laser Sintering (DMLS): DMLS is used for producing metal components by sintering metal powders with a laser, allowing for the manufacture of complex, high-strength parts for aerospace, automotive, and medical industries.

For a deeper dive into the mechanics and evolution of these processes, this detailed explanation of 3D printing technology offers further insights.

Applications Across Industries

The versatility of additive manufacturing has led to its adoption in a wide range of sectors. Some of the most prominent applications include:

- Prototyping: Designers and engineers use 3D printing to quickly produce prototypes, test concepts, and iterate designs before committing to mass production.

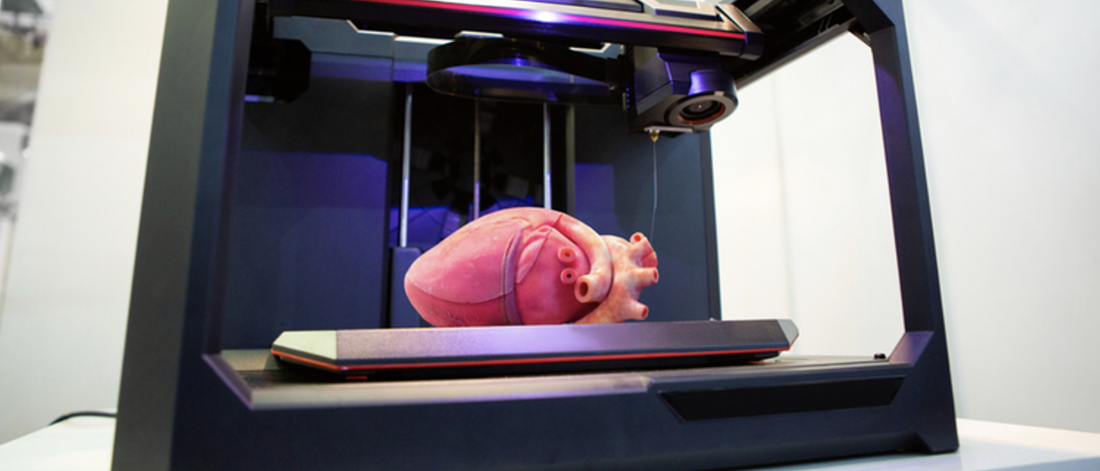

- Medical Devices: Customized implants, prosthetics, and dental devices are now routinely produced using additive methods, tailored to individual patients for improved outcomes.

- Aerospace and Automotive: Lightweight components, complex geometries, and rapid tooling are made possible, reducing both weight and production costs.

- Consumer Products: From eyewear to footwear, manufacturers leverage 3D printing for customization and small-batch production.

- Architecture and Construction: Large-scale printers can fabricate building components or even entire structures, pushing the boundaries of design and sustainability.

Advantages and Challenges of Layered Manufacturing

The benefits of additive manufacturing are significant. It enables rapid design iterations, reduces material waste, and allows for the production of highly customized or complex parts. Small businesses and startups can access manufacturing capabilities that were once only available to large corporations, leveling the playing field and fostering innovation.

However, there are also challenges to consider. Print speeds can be slow for larger objects, and material choices, while expanding, are still more limited than with traditional manufacturing. Surface finish and mechanical properties may require post-processing or additional testing, especially for critical applications. As the technology matures, ongoing research and development are addressing these limitations, making additive processes more robust and versatile.

Materials Used in Additive Processes

The range of materials compatible with additive manufacturing continues to grow. Common options include:

- Thermoplastics: PLA, ABS, PETG, and nylon are popular for FDM printing due to their ease of use and affordability.

- Photopolymers: Used in SLA and DLP printers, these resins offer high detail and smooth surfaces, suitable for prototypes and dental models.

- Metals: Stainless steel, titanium, aluminum, and cobalt-chrome are processed using SLS or DMLS for functional parts in demanding environments.

- Composites: Materials reinforced with carbon fiber or glass fiber provide enhanced strength and stiffness.

- Ceramics and Others: Specialized printers can process ceramics, waxes, and even food materials for niche applications.

Future Trends in Digital Fabrication

As additive manufacturing technology advances, several trends are shaping its future. Multi-material printing is enabling the creation of parts with varying properties in a single build. Automation and artificial intelligence are streamlining design and production workflows. Sustainability is also a growing focus, with efforts to develop recyclable materials and energy-efficient processes.

The integration of 3D printing with other digital manufacturing tools is paving the way for smart factories and mass customization. As costs decrease and capabilities expand, more businesses and individuals are expected to adopt these technologies, further transforming how products are designed and made.

Frequently Asked Questions

What is the main difference between additive and traditional manufacturing?

Additive manufacturing builds objects layer by layer from digital designs, while traditional manufacturing typically removes material from a solid block or uses molds to shape parts. This fundamental difference allows for greater design flexibility and reduced material waste.

Can 3D printed parts be used for end-use products?

Yes, many industries now use 3D printed components for final products, especially when customization, complex geometry, or small production runs are required. However, the suitability depends on the material, process, and application requirements.

Is additive manufacturing cost-effective for mass production?

While 3D printing excels at prototyping and low-volume manufacturing, traditional methods are often more economical for large-scale production. However, as technology improves and material costs decrease, additive methods are becoming increasingly competitive for certain mass-produced items.