The history of 3D printing is a fascinating journey that spans decades of technological progress, creative experimentation, and groundbreaking innovation. What began as a theoretical concept has evolved into a transformative force across industries, from manufacturing and healthcare to art and education. Today, additive manufacturing—another term for 3D printing—stands at the forefront of modern production, enabling rapid prototyping, custom fabrication, and even the creation of complex structures that were once impossible to produce.

This article explores the origins, key milestones, and latest breakthroughs in the evolution of 3D printing. Along the way, you’ll find practical insights, essential terminology, and resources to deepen your understanding of this dynamic field. For those new to the topic, you may also want to review 3D printing technology explained for a foundational overview.

Early Concepts and the Birth of Additive Manufacturing

The roots of 3D printing’s history can be traced back to the 1980s, when researchers began exploring ways to create objects layer by layer, rather than subtracting material as in traditional manufacturing. The idea of building parts additively was revolutionary, allowing for greater design freedom and material efficiency.

In 1981, Dr. Hideo Kodama of Japan published the first account of a rapid prototyping system using photopolymers. Although his patent application was not successful, his work laid the groundwork for future developments. Just a few years later, Charles Hull invented stereolithography (SLA), a process that uses ultraviolet lasers to solidify liquid resin, forming precise 3D objects. Hull’s invention led to the founding of 3D Systems in 1986 and the commercialization of the first SLA machines.

Key Milestones in the Development of 3D Printing

The late 1980s and early 1990s saw a surge of innovation in additive manufacturing. Several new techniques emerged, each with unique advantages and applications:

- Stereolithography (SLA): The first commercial 3D printing technology, ideal for highly detailed prototypes.

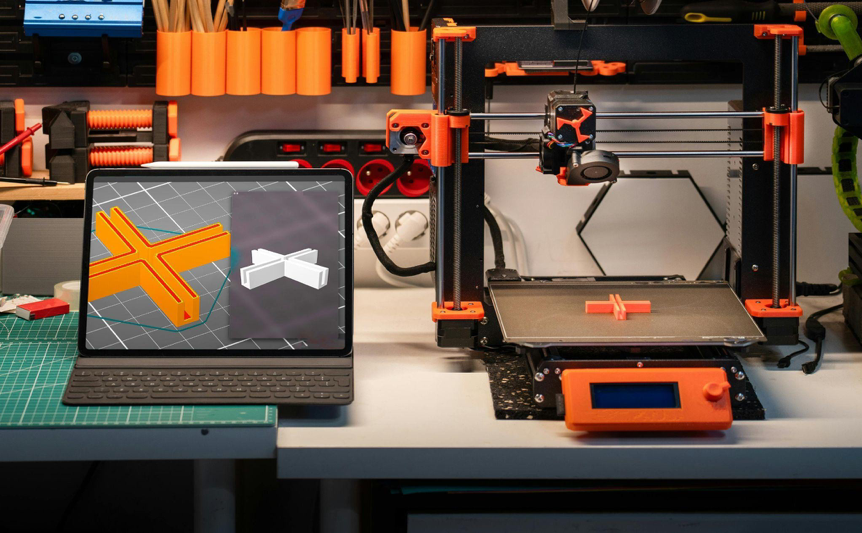

- Fused Deposition Modeling (FDM): Developed by Scott Crump in 1989, FDM extrudes melted thermoplastic to build objects layer by layer. This method became the foundation for many consumer 3D printers.

- Select Laser Sintering (SLS): Invented by Dr. Carl Deckard, SLS uses lasers to fuse powdered materials, enabling the production of durable, functional parts.

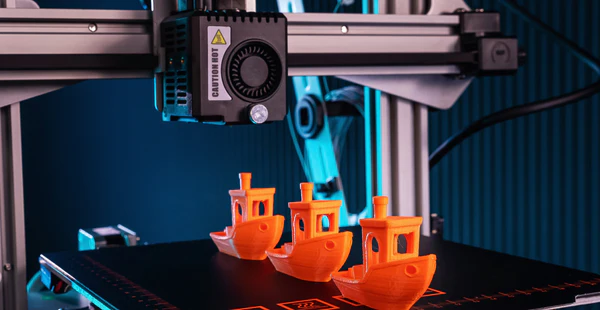

By the mid-1990s, 3D printing was gaining traction in industrial settings for rapid prototyping, reducing the time and cost required to bring new products to market. As patents began to expire in the 2000s, open-source projects and affordable desktop printers made the technology accessible to hobbyists, educators, and small businesses.

Expansion into New Materials and Industries

As the evolution of 3D printing continued, researchers and engineers experimented with a wide range of materials. Beyond plastics and resins, printers began to use metals, ceramics, composites, and even biological substances. This expansion unlocked new possibilities in sectors such as aerospace, automotive, dental, and medical device manufacturing.

Metal additive manufacturing, for example, has enabled the production of lightweight, complex components for jet engines and satellites. In healthcare, custom prosthetics, dental implants, and even bioprinted tissues have become reality. The flexibility of additive processes allows for rapid iteration and on-demand production, reducing waste and inventory.

Modern Innovations and Future Directions

The last decade has seen additive manufacturing move from prototyping to full-scale production. Advances in printer speed, resolution, and material diversity have enabled mass customization and the creation of end-use parts. Some of the most exciting recent developments include:

- Multi-material printing: The ability to print with several materials in a single build, combining properties like flexibility and strength.

- Large-scale construction: 3D printing is now used to build houses, bridges, and infrastructure components, reducing construction time and cost.

- Bioprinting: Researchers are developing ways to print living tissues and organs, with the potential to revolutionize medicine.

- On-demand manufacturing: Companies can produce spare parts or custom products locally, minimizing supply chain disruptions.

The accessibility of desktop 3D printers has also empowered makers, students, and entrepreneurs to turn ideas into reality. For a closer look at the practical steps involved, see how 3D printing works for beginners.

Impact on Manufacturing and Society

The influence of additive manufacturing extends far beyond the factory floor. Its adoption has led to shorter product development cycles, lower costs, and more sustainable production methods. In education, 3D printers are used to teach STEM concepts and foster creativity. Artists and designers use the technology to produce intricate sculptures, jewelry, and fashion pieces that would be difficult or impossible to craft by hand.

As the technology matures, regulatory standards and best practices are emerging to ensure quality and safety. The ability to produce complex geometries with minimal waste aligns with global efforts toward sustainability and resource efficiency.

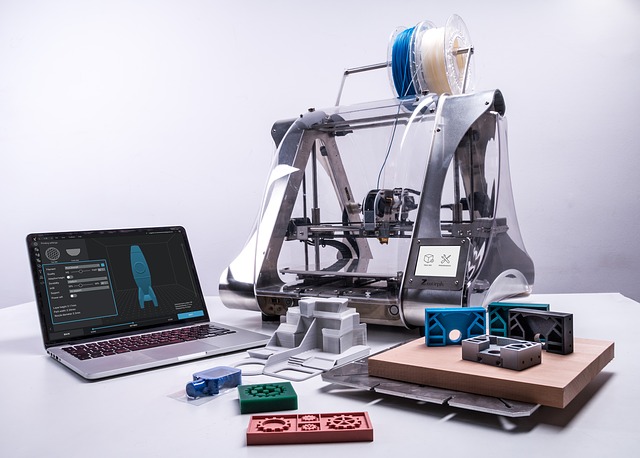

Choosing the Right 3D Printer for Your Needs

With so many options available, selecting the appropriate printer depends on your intended application, material requirements, and budget. Industrial users may require high-precision metal printers, while hobbyists and educators often start with affordable FDM or resin models. For a comprehensive overview of available machines, explore the range of professional and desktop 3D printers on the market.

If you’re interested in the broader context of manufacturing, the article introduction to additive manufacturing provides a helpful background on the basics and applications of this technology.

Frequently Asked Questions

Who invented 3D printing and when?

Charles Hull is widely credited with inventing the first commercial 3D printing process, known as stereolithography (SLA), in 1984. However, earlier concepts and research by Dr. Hideo Kodama in Japan also contributed to the foundation of additive manufacturing.

What materials can be used in 3D printing today?

Modern 3D printers can use a variety of materials, including plastics (such as PLA and ABS), resins, metals (like titanium and stainless steel), ceramics, composites, and even biological substances for medical applications.

How has 3D printing changed manufacturing?

Additive manufacturing has enabled rapid prototyping, mass customization, reduced waste, and the ability to produce complex parts that are difficult or impossible to make with traditional methods. It has also shortened development cycles and made on-demand production more feasible.

Where can I learn more about the basics of 3D printing?

For beginners, what is 3D printing offers a clear explanation of how the technology works and its impact on modern manufacturing.