The world of 3D printing offers a variety of technologies, each with its unique strengths and applications. Among the most popular are Fused Deposition Modeling (FDM) and Stereolithography (SLA). Understanding the distinctions between these two methods is essential for anyone considering which approach best suits their needs, whether for prototyping, manufacturing, or hobbyist projects. This article explores the main differences, advantages, and disadvantages of FDM and SLA, helping you make an informed decision.

If you’re new to additive manufacturing, you might also find it helpful to review our guide to types of 3D printing technologies for a broader overview of available options.

Understanding the Basics of FDM and SLA

Both FDM and SLA are forms of additive manufacturing, but they use different processes and materials to create objects layer by layer. FDM relies on thermoplastic filaments, while SLA uses liquid resin cured by light. These fundamental differences impact everything from print quality to cost and post-processing requirements.

How FDM Printing Works

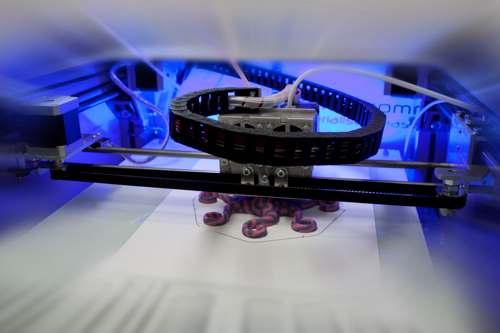

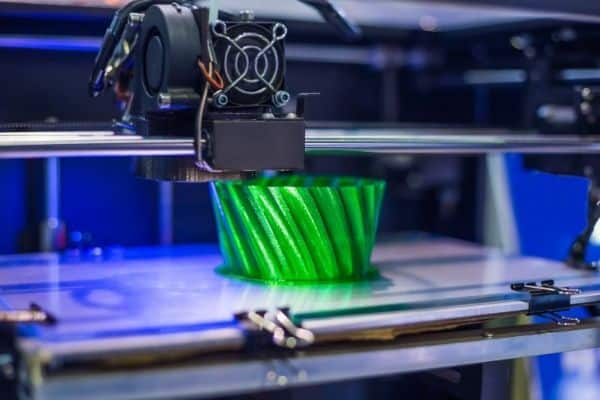

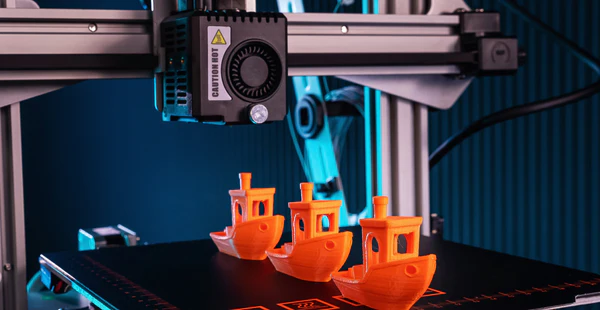

FDM, or Fused Deposition Modeling, is one of the most accessible and widely used 3D printing technologies. It works by heating a thermoplastic filament and extruding it through a nozzle, which moves along a predetermined path to build objects layer by layer. This method is popular for its affordability, ease of use, and compatibility with a wide range of materials.

How SLA Printing Differs

SLA, or Stereolithography, uses a vat of liquid photopolymer resin and a light source (usually a laser or LCD screen) to cure the resin layer by layer. This process allows for extremely fine details and smooth surface finishes, making it ideal for applications where precision and aesthetics are critical.

Key Differences Between FDM and SLA Methods

When comparing these two popular 3D printing technologies, several factors stand out. The choice between FDM and SLA often depends on the intended use, required detail, budget, and post-processing preferences.

| Aspect | FDM | SLA |

|---|---|---|

| Material | Thermoplastic filament (PLA, ABS, PETG, etc.) | Photopolymer resin |

| Print Quality | Good for functional parts, visible layer lines | High detail, smooth surfaces |

| Speed | Generally faster for larger prints | Slower, especially for large objects |

| Cost | Lower printer and material costs | Higher printer and resin costs |

| Post-Processing | Minimal, mostly removing supports | Requires washing, curing, and sometimes sanding |

| Applications | Prototyping, mechanical parts, hobby projects | Miniatures, dental models, jewelry, detailed prototypes |

Advantages and Disadvantages of Each Approach

Benefits of FDM Technology

- Affordability: FDM printers and filaments are generally less expensive, making them accessible for beginners and small businesses.

- Material Variety: A wide range of thermoplastics is available, including specialty filaments like flexible or composite materials.

- Ease of Use: Setup and maintenance are straightforward, with a large community for support.

- Speed: Suitable for larger prints and functional prototypes that do not require ultra-fine detail.

Drawbacks of FDM Printing

- Surface Finish: Layer lines are often visible, which can affect the aesthetics of the final product.

- Detail Limitations: Not ideal for extremely small or intricate parts.

- Strength: Parts may have anisotropic properties, meaning strength varies depending on print orientation.

Strengths of SLA Printing

- Exceptional Detail: SLA can produce highly detailed and smooth models, ideal for applications where precision is critical.

- Surface Quality: Finished parts often require less sanding or finishing work.

- Complex Geometries: Supports can be finer and easier to remove, enabling more complex designs.

Limitations of SLA Technology

- Cost: Resin printers and consumables are typically more expensive than their FDM counterparts.

- Post-Processing: Requires additional steps such as washing in isopropyl alcohol and UV curing.

- Material Handling: Resins can be messy and require careful handling due to toxicity and odor.

- Print Size: Most desktop SLA printers have smaller build volumes compared to FDM machines.

Choosing the Right 3D Printing Technology for Your Needs

Deciding between FDM and SLA depends on your priorities. If you need functional prototypes, larger prints, or are working with a limited budget, FDM is a practical choice. For projects where fine detail and surface finish are paramount—such as miniatures, dental models, or jewelry—SLA is often the better option.

For a deeper dive into the fundamentals, our comprehensive guide to 3D printing technology explained covers the basics and more advanced concepts.

Applications and Use Cases

Both FDM and SLA have found their place in a wide range of industries. FDM is commonly used for prototyping, mechanical parts, and educational purposes. Its affordability and speed make it suitable for iterative design and functional testing. SLA, on the other hand, is preferred for applications demanding high resolution and smooth finishes. This includes dental and medical models, intricate figurines, and master patterns for molding.

If you’re interested in how these technologies are shaping manufacturing, you might enjoy our article on what is 3D printing and its impact on modern production methods.

Maintenance and Post-Processing Considerations

Maintenance requirements differ between the two technologies. FDM machines typically need regular nozzle cleaning and bed leveling, while SLA printers require careful handling of resin vats and routine cleaning of optical components. Post-processing for FDM is usually limited to support removal and light sanding, whereas SLA parts must be washed, cured, and sometimes sanded for optimal results.

Cost Comparison: FDM and SLA

Cost is a significant factor for many users. FDM printers are generally more affordable, with lower material costs and less expensive maintenance. SLA printers have higher upfront costs and require ongoing purchases of resin and cleaning supplies. However, for certain applications, the superior detail and finish of SLA may justify the additional expense.

For a broader perspective on the process, see our step-by-step overview of how 3D printing works.

Further Reading and Resources

To expand your understanding, visit this in-depth explanation of what 3D printing is for more technical details and industry insights.

Frequently Asked Questions

Which is better for beginners, FDM or SLA?

FDM is generally recommended for beginners due to its lower cost, easier setup, and wide community support. SLA offers higher detail but involves more complex post-processing and handling.

Can FDM and SLA printers use the same materials?

No, FDM uses thermoplastic filaments such as PLA or ABS, while SLA relies on liquid photopolymer resins. Each technology requires materials specifically designed for its process.

What are the main maintenance differences between FDM and SLA?

FDM printers need regular nozzle cleaning and bed leveling. SLA machines require cleaning of resin vats, optical components, and careful handling of uncured resin. Post-processing for SLA is also more involved.

Is it possible to achieve high detail with FDM printers?

While FDM can produce good results, it cannot match the fine detail and smooth finish achievable with SLA. For extremely intricate or small parts, SLA is preferred.

Conclusion

Both FDM and SLA offer unique benefits and limitations. Your choice should be guided by your project requirements, budget, and desired print quality. By understanding the core differences and practical considerations, you can select the most suitable 3D printing technology for your needs.

For more foundational knowledge, our introduction to additive manufacturing covers the basics and applications of 3D printing in various industries.