Offset printing remains a staple in the printing industry due to its high-quality output and cost-effectiveness for large print runs. However, like any other process, it is not immune to errors. Understanding the common offset printing mistakes can save you time, money, and ensure your prints are of the highest quality.

Understanding the Basics of Offset Printing

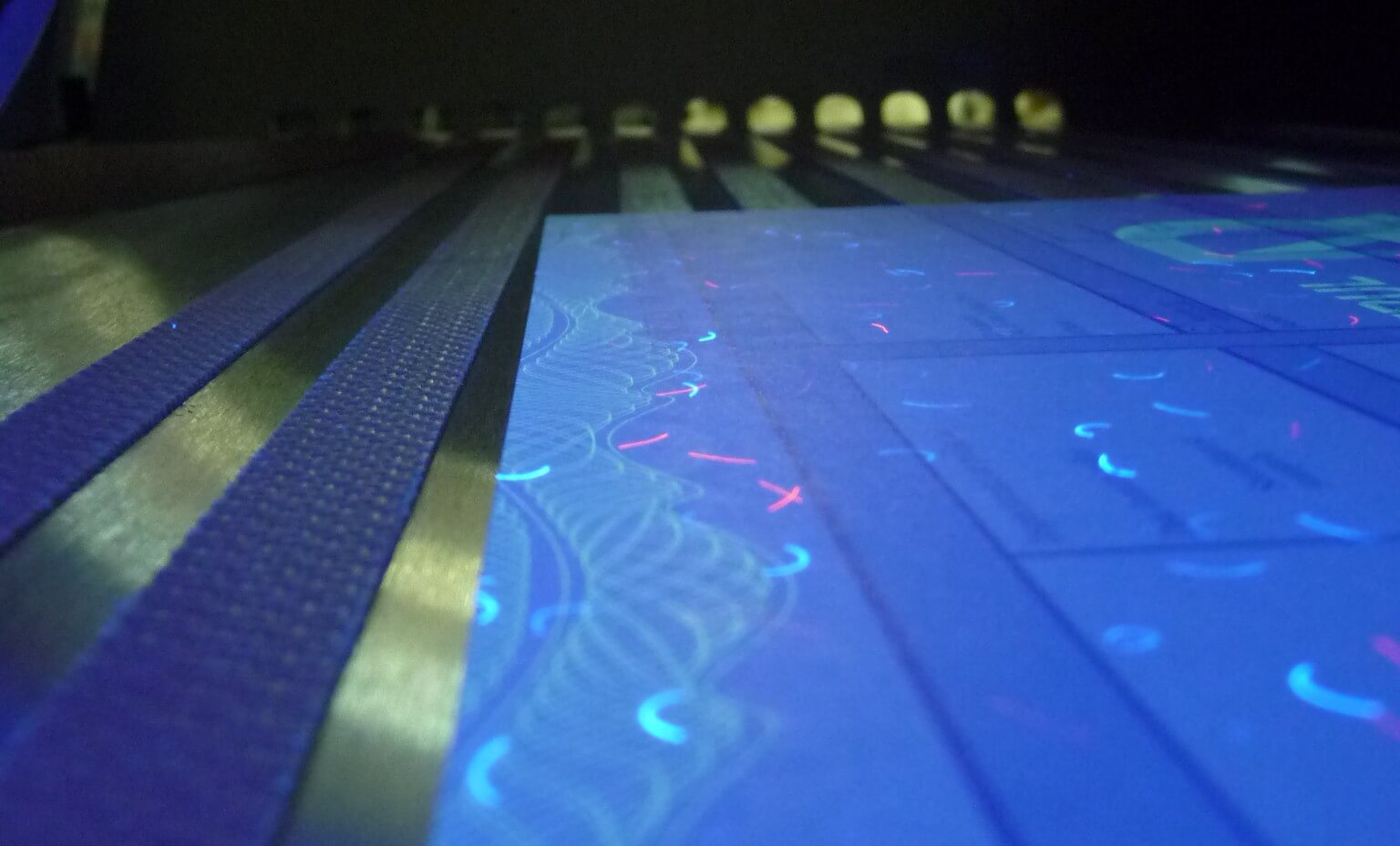

Before diving into the mistakes, it is essential to comprehend what offset printing entails. This method involves transferring an inked image from a plate to a rubber blanket and then onto the printing surface. The technique is favored for its ability to produce sharp and clean images and texts.

The Importance of Proper Plate Preparation

One of the most common offset printing mistakes is improper plate preparation. The printing plate must be correctly set up to ensure accurate and consistent prints. Any error here can lead to misaligned images or texts, resulting in a waste of resources.

Ink and Water Balance

Achieving the right balance between ink and water is crucial in offset printing. Too much ink can lead to smudging, while too much water can cause the ink to become diluted, affecting the print quality. Regularly checking and adjusting the balance can prevent these issues.

Paper Quality and Selection

Choosing the wrong type of paper is another frequent mistake. The paper’s quality can significantly impact the final print. It’s essential to select the right paper for your specific project, considering factors such as weight, texture, and absorbency. For more insights on paper selection, check out this guide on offset vs digital printing.

Identifying and Correcting Common Mistakes

Misregistration

Misregistration occurs when the different color plates do not align correctly. This results in a blurred or shadowed image. Regularly checking the alignment of plates and making necessary adjustments can prevent this issue.

Color Variation

Color consistency is vital in printing. Variations in color can occur due to ink density changes or improper calibration. Ensuring that your printing press is well-maintained and regularly calibrated can help maintain color consistency.

Smudging and Setoff

Smudging happens when the ink does not dry quickly enough, causing it to smear. Setoff, on the other hand, is when wet ink transfers from one sheet to another. Both can be minimized by adjusting drying times and using appropriate anti-setoff powders.

Maintaining Equipment and Processes

Regular Maintenance

Regular maintenance of printing equipment is crucial in preventing many of the common offset printing mistakes. This includes cleaning, lubricating, and replacing worn-out parts to ensure the press operates smoothly.

Training and Skill Development

Ensuring that staff are well-trained and up-to-date with the latest printing techniques can significantly reduce errors. Continuous learning and skill development should be part of the company’s culture.

Cost Implications of Printing Mistakes

Printing mistakes not only affect the quality of the final product but also have financial implications. Wasted materials and time can increase production costs. Understanding these implications can motivate businesses to invest in quality control and error prevention measures.

Frequently Asked Questions

What are the most common offset printing mistakes?

Some common mistakes include improper plate preparation, incorrect ink and water balance, misregistration, and color variation.

How can I prevent smudging in offset printing?

To prevent smudging, ensure that the ink drying time is optimized and consider using anti-setoff powders.

Why is regular equipment maintenance important?

Regular maintenance helps prevent breakdowns and ensures that the printing press operates efficiently, reducing the risk of errors.

For more information on how to effectively utilize offset printing for your business, visit offset printing for small businesses. Additionally, learn about the impact of AI in printing to stay ahead with technology advancements.

This article contains affiliate links. We may earn a commission at no extra cost to you.