In today’s global market, counterfeiting poses a significant threat to businesses and consumers alike. As the demand for authentic products increases, so does the need for effective anti-counterfeit packaging solutions. To understand the impact and effectiveness of these solutions, we delve into various case studies in anti-counterfeit packaging. These case studies provide valuable insights and strategies for businesses looking to safeguard their products and brand integrity.

Understanding the Importance of Anti-Counterfeit Packaging

The rise of counterfeit goods has necessitated the development of robust anti-counterfeit packaging measures. These measures not only protect consumers but also help businesses maintain their reputation and market share. By examining case studies in anti-counterfeit packaging, we can explore the innovative approaches companies have adopted to combat this pervasive issue.

Case Study 1: Pharmaceutical Serialization

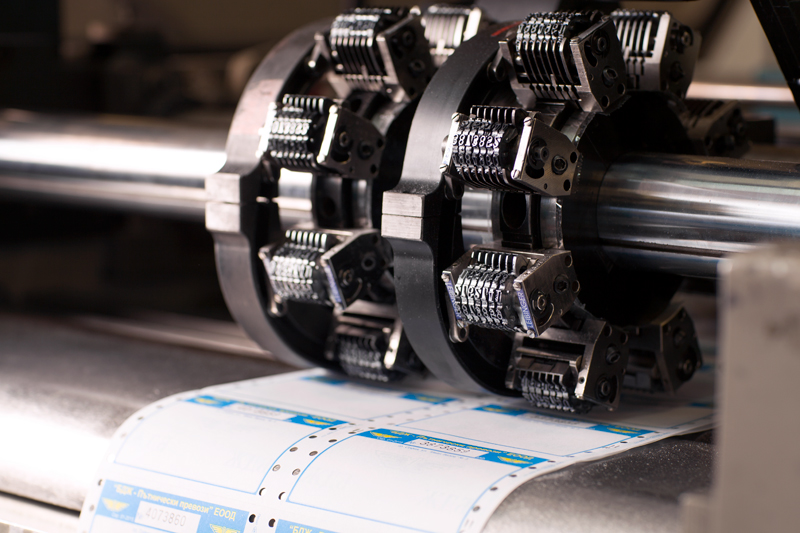

One notable example of effective anti-counterfeit packaging is in the pharmaceutical industry. Serialization, a method involving unique identification codes on each product, has proven to be a powerful tool against counterfeiting. Companies have implemented serialization to track and trace products throughout the supply chain, ensuring authenticity and safety for consumers. For more information on pharmaceutical serialization compliance, visit Pharmaceutical Serialization Compliance.

Case Study 2: Fashion Industry Solutions

The fashion industry is another sector heavily impacted by counterfeiting. Brands have adopted various anti-counterfeit packaging strategies, such as holographic labels and RFID tags, to protect their products. These technologies not only deter counterfeiters but also enhance the customer experience by providing a means of verifying the authenticity of their purchases. Explore more about counterfeit case studies in fashion through Counterfeit Case Studies in Fashion.

Case Study 3: Cost-Effective Measures

Implementing anti-counterfeit packaging solutions can be costly, but companies have found innovative ways to balance expenses with effectiveness. By investing in cost-effective technologies, businesses can protect their products without significantly impacting their budget. Learn more about the cost of implementing anti-counterfeit printing at Cost of Implementing Anti-Counterfeit Printing.

Emerging Technologies in Anti-Counterfeit Packaging

As technology advances, so do the methods for combating counterfeiting. The integration of digital solutions, such as blockchain and QR codes, offers new avenues for ensuring product authenticity. These technologies provide consumers with easy access to product information, reinforcing trust and loyalty.

Blockchain for Supply Chain Integrity

Blockchain technology has garnered attention for its potential to enhance supply chain transparency. By recording every transaction in a secure and immutable ledger, businesses can ensure the authenticity of their products from production to purchase.

QR Codes for Consumer Engagement

QR codes have become a popular tool for engaging consumers and verifying product authenticity. By scanning a QR code, consumers can access detailed information about the product’s origin, ingredients, and authenticity. This not only enhances brand transparency but also empowers consumers to make informed purchasing decisions.

Future Trends in Anti-Counterfeit Packaging

The future of anti-counterfeit packaging lies in continuous innovation and adaptation. As counterfeiters become more sophisticated, businesses must stay ahead of the curve by investing in emerging technologies and strategies. The ongoing development of smart packaging, which integrates sensors and connectivity, holds promise for further enhancing product security.

Smart Packaging Innovations

Smart packaging combines traditional packaging with advanced technologies to provide real-time data and monitoring. This includes temperature sensors, tamper-evident features, and interactive elements that improve product safety and consumer experience.

Collaborative Efforts and Industry Standards

To effectively combat counterfeiting, industries must collaborate and establish standardized guidelines. By working together, companies can share best practices, technologies, and strategies to create a unified front against counterfeiters. For insights into industry standards, visit Anti-Counterfeit Printing Industry Standards.

Conclusion

The case studies in anti-counterfeit packaging offer valuable lessons for businesses seeking to protect their products and consumers. By adopting innovative technologies and strategies, companies can effectively combat counterfeiting and maintain their brand integrity. As the landscape of counterfeiting continues to evolve, staying informed and proactive is essential.

FAQs

What is anti-counterfeit packaging?

Anti-counterfeit packaging refers to the use of technologies and strategies designed to prevent the production and sale of counterfeit goods. It aims to protect consumers and businesses by ensuring product authenticity and safety.

How can businesses implement anti-counterfeit measures?

Businesses can implement anti-counterfeit measures by adopting technologies such as serialization, holographic labels, RFID tags, and blockchain. These solutions help track and verify the authenticity of products throughout the supply chain.

Why is anti-counterfeit packaging important?

Anti-counterfeit packaging is important because it protects consumers from harmful fake products, safeguards businesses’ reputation and market share, and ensures compliance with industry regulations.

For more information on security printing techniques, you can visit Security Printing.

This article contains affiliate links. We may earn a commission at no extra cost to you.