The rise of 3D printing has transformed how products are designed, prototyped, and manufactured across industries. This innovative approach, also known as additive manufacturing, offers a range of advantages over traditional production methods. From speeding up development cycles to reducing costs and enabling unprecedented customization, the technology is reshaping what’s possible for businesses, engineers, and hobbyists alike.

In this article, we’ll explore the key benefits of 3D printing, focusing on how it delivers faster results, lowers expenses, and supports flexible, on-demand production. If you’re new to the subject and want to understand the basics, you might find 3D printing technology explained a useful starting point.

Accelerated Prototyping and Production

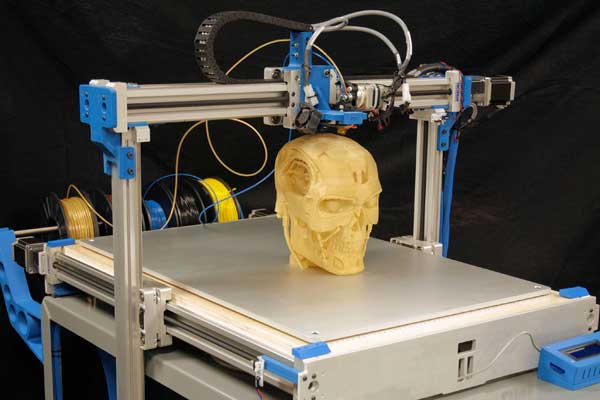

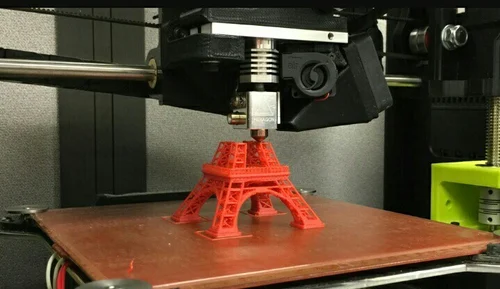

One of the most significant advantages of additive manufacturing is its ability to dramatically speed up the prototyping process. Traditional manufacturing often requires custom tooling and lengthy setup times, which can delay product development by weeks or even months. In contrast, 3D printing allows for rapid creation of prototypes directly from digital files, enabling designers and engineers to iterate quickly and efficiently.

This fast turnaround is especially valuable for startups and research teams that need to test ideas, refine designs, or present concepts to stakeholders without waiting for expensive molds or machining. By reducing the time from concept to physical model, organizations can bring products to market faster and respond more nimbly to feedback or changing requirements.

Lower Costs and Resource Efficiency

Cost savings are a core reason why many businesses are adopting this technology. Unlike subtractive manufacturing, which carves objects from larger blocks of material (often resulting in significant waste), 3D printing builds items layer by layer, using only the material required for the final product. This approach minimizes waste and can lead to substantial savings on raw materials.

Additionally, the absence of specialized tooling or molds means that setup costs are minimal, especially for low-volume or custom production runs. For small businesses, inventors, and educators, this opens up new opportunities to create functional parts, models, or teaching aids without the financial barriers of traditional manufacturing.

Unmatched Design Flexibility

Another compelling benefit of 3D printing is the freedom it gives designers and engineers to create complex geometries that would be difficult or impossible with conventional methods. Intricate internal channels, lattice structures, and organic shapes can be produced without additional cost or complexity.

This flexibility is particularly valuable in industries such as aerospace, automotive, and healthcare, where lightweight components, custom implants, or optimized structures can lead to better performance and patient outcomes. Customization is also straightforward—each item can be tailored to individual needs without retooling or extra expense.

For a deeper dive into how this technology works and the possibilities it unlocks, see how 3D printing works.

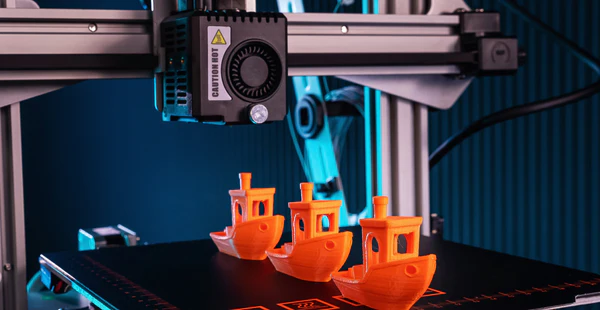

On-Demand and Decentralized Manufacturing

Additive manufacturing supports a shift toward on-demand production and distributed supply chains. Instead of maintaining large inventories or relying on distant suppliers, companies can produce parts as needed, close to the point of use. This reduces storage costs, shortens lead times, and helps mitigate risks associated with supply chain disruptions.

In fields like healthcare, this means custom prosthetics or surgical guides can be produced locally and delivered to patients more quickly. For manufacturers, spare parts and replacement components can be printed on-site, reducing downtime and logistics expenses.

Environmental Impact and Sustainability

Reducing material waste and enabling local production are not just cost-saving measures—they also contribute to sustainability. By using only the necessary amount of material and minimizing transportation needs, additive manufacturing can lower the environmental footprint of manufacturing operations.

Many 3D printers are now compatible with recycled or biodegradable materials, further supporting eco-friendly initiatives. As the technology matures, its role in sustainable manufacturing is expected to grow, offering new ways to balance productivity with environmental responsibility.

Expanding Applications Across Industries

The benefits of 3D printing are being realized in a growing number of sectors. In healthcare, it’s used for custom prosthetics, dental implants, and even bioprinting tissues. The automotive and aerospace industries rely on the technology for lightweight parts and rapid prototyping. Consumer goods companies use it to create custom jewelry, eyewear, and home décor.

Education and research institutions leverage 3D printers for hands-on learning, model creation, and experimentation. Even the construction industry is exploring large-scale printers for building components and homes.

For a comprehensive overview of how additive manufacturing is being applied, introduction to additive manufacturing provides further insights.

Getting Started and Learning More

If you’re interested in exploring this technology for your business or personal projects, there are many resources available. Guides such as the complete 3D printing guide from Xometry offer practical advice on choosing the right printer, materials, and workflow for your needs.

As the technology becomes more accessible and affordable, the barriers to entry continue to fall. Whether you’re prototyping a new invention, producing custom parts, or simply experimenting with creative ideas, the opportunities are expanding every day.

Frequently Asked Questions

What materials can be used in 3D printing?

A wide range of materials are available, including various plastics (like PLA, ABS, PETG), resins, metals (such as titanium, aluminum, and stainless steel), ceramics, and even some composites. The choice depends on the printer type and the intended application.

Is 3D printing suitable for mass production?

While additive manufacturing excels at prototyping and small-batch production, advances in speed and scalability are making it increasingly viable for certain mass production scenarios, especially where customization or complex geometries are required.

How does 3D printing compare to traditional manufacturing in terms of cost?

For low-volume, custom, or complex parts, additive manufacturing is often more cost-effective due to minimal setup and reduced material waste. However, for very large production runs of simple parts, traditional methods may still offer lower per-unit costs.

Where can I learn more about 3D printing basics?

If you’re just starting out, what is 3D printing provides a beginner-friendly introduction to the core concepts and terminology.