Achieving reliable first-layer adhesion is one of the most important steps in successful 3D printing. Without a well-prepared build surface, prints are prone to warping, shifting, or even complete detachment from the bed. This guide explores a range of adhesion methods for 3D printing, focusing on practical bed preparation techniques for both beginners and experienced makers. Understanding these approaches can help you minimize print failures and improve the overall quality of your 3D-printed objects.

Whether you’re working with PLA, ABS, PETG, or resin, the right surface treatment and setup can make a significant difference. We’ll cover the most common strategies, from basic cleaning to advanced adhesion aids, and discuss how to choose the best option for your printer and material. For those interested in tackling more complex shapes, our article on printing complex geometries offers additional tips for challenging prints.

Why Bed Adhesion Matters in 3D Printing

The first layer of a print acts as the foundation for the entire object. If it doesn’t stick properly, issues like warping, curling, or shifting can occur, leading to failed prints and wasted material. Good adhesion ensures that each layer is built precisely on top of the previous one, maintaining dimensional accuracy and surface quality.

Factors influencing adhesion include bed temperature, surface material, cleanliness, and the type of filament or resin used. By understanding these variables, you can select the most effective bed preparation techniques for your specific setup.

Basic Bed Preparation Steps

Before applying any specialized adhesion aids, start with these fundamental steps to maximize your chances of a successful print:

- Clean the Build Surface: Remove dust, oils, and residue using isopropyl alcohol or a mild detergent. Even small contaminants can reduce adhesion.

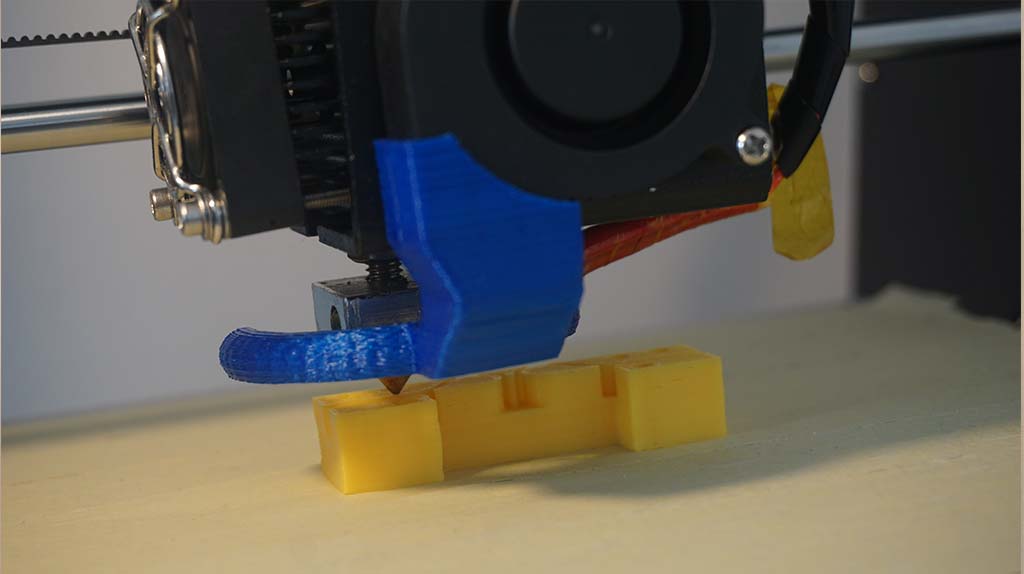

- Level the Bed: Ensure the print bed is flat and at the correct distance from the nozzle. Manual or automatic leveling systems can help maintain consistency.

- Check Bed Temperature: Use the recommended temperature for your filament. For example, PLA typically adheres well at 50–60°C, while ABS may require 90–110°C.

Consistent maintenance of these basics lays the groundwork for more advanced adhesion methods for 3D printing.

Popular Adhesion Aids and Surface Treatments

When basic cleaning and leveling aren’t enough, several products and techniques can boost first-layer grip. Here are some of the most widely used options:

1. Glue Sticks and Adhesive Sprays

Applying a thin layer of glue stick or a specialized adhesive spray creates a tacky surface that helps prints stay put. These are especially useful for materials like PLA and PETG. They’re easy to apply and clean up, making them a popular choice for everyday printing.

2. Painter’s Tape and Build Surface Films

Blue painter’s tape is a classic solution for PLA and other low-temperature filaments. It provides a textured surface that improves grip and can be replaced easily when worn. Modern alternatives include PEI sheets, BuildTak, and other proprietary films designed for repeated use and compatibility with a range of materials.

3. Hairspray and Sugar Water

Some users apply a light mist of unscented hairspray or a homemade sugar-water solution to the bed. These methods are cost-effective and can work well for certain filaments, but they may leave residue and require more frequent cleaning.

4. Specialized Build Plates

Glass, PEI, and flexible steel build plates each offer unique adhesion properties. Glass provides a smooth finish and is easy to clean, while PEI sheets are durable and compatible with many materials. Flexible plates allow for easy part removal, reducing the risk of damaging prints.

Advanced Techniques for Reliable First Layers

For challenging prints or demanding materials, advanced strategies can further improve adhesion:

- Brims and Rafts: Adding a brim or raft in your slicer software increases the surface area of the first layer, helping prevent warping and lifting.

- Adjusting First Layer Settings: Lowering print speed, increasing extrusion width, or slightly reducing the nozzle height for the first layer can enhance grip.

- Enclosures: For ABS and other temperature-sensitive plastics, enclosing the printer helps maintain a stable environment and reduces warping.

If you’re interested in optimizing your digital files for better printability, our resource on 3D printing file formats explained covers how file choices can impact your results.

Material-Specific Adhesion Strategies

Different filaments and resins require tailored approaches to bed preparation:

| Material | Recommended Bed Surface | Adhesion Aid |

|---|---|---|

| PLA | Glass, PEI, Painter’s Tape | Glue Stick, Blue Tape |

| ABS | Heated Glass, PEI | ABS Slurry, Hairspray, Enclosure |

| PETG | PEI, Glass | Glue Stick, Avoid Tape (can fuse) |

| Resin | Textured Metal, FEP Film | Ensure Cleanliness, Leveling |

Common Problems and Troubleshooting Tips

Even with careful preparation, issues can arise. Here are some common problems and how to address them:

- Warping: Increase bed temperature, use a brim or raft, and check for drafts in the printing area.

- Poor Adhesion: Re-clean the bed, re-level, and try a different adhesion aid suited to your material.

- Over-Adhesion: If parts are difficult to remove, reduce bed temperature or switch to a less aggressive surface.

For additional design-related advice, see our article on how to design for 3D printing, which covers model adjustments that can improve print success.

Further Reading and Resources

For a deeper dive into 3D printing technology, materials, and troubleshooting, the comprehensive 3D printing guide by Hubs is an excellent resource. It covers everything from printer types to advanced material science, helping you make informed decisions for your projects.

If you’re interested in refining your digital models, our guide on 3D modeling tips for printing can help you avoid common design pitfalls and achieve better results.

Frequently Asked Questions

What is the best way to prepare a 3D printer bed for PLA?

For PLA, start by cleaning the bed thoroughly with isopropyl alcohol. Use blue painter’s tape or a PEI sheet for added grip, and apply a thin layer of glue stick if needed. Maintain the bed temperature between 50–60°C for optimal adhesion.

How do I prevent warping when printing with ABS?

Warping with ABS can be minimized by using a heated bed (90–110°C), enclosing the printer to maintain a stable environment, and applying an ABS slurry or hairspray to the bed. Adding a brim or raft in your slicer can also help anchor the print.

Can I use the same adhesion method for all filament types?

Not all filaments respond the same way to each method. For example, PETG can bond too strongly to PEI or tape, making part removal difficult. Always check the manufacturer’s recommendations and test different surfaces and aids to find what works best for your material.