3D printing technology explained is a topic that’s rapidly gaining attention as more people discover the possibilities of creating objects layer by layer from digital designs. Whether you’re curious about how these machines work, what you can make with them, or how to get started, this guide will walk you through the essentials in clear, practical terms. From the basics of additive manufacturing to the types of printers and materials available, understanding this innovative process can open up new opportunities for both hobbyists and professionals.

As you explore the fundamentals, you’ll find that 3D printing isn’t just for engineers or designers. It’s accessible to anyone interested in prototyping, customizing products, or even just experimenting with creative ideas. For those eager to dive deeper, resources like in-depth articles on modern 3D printing applications provide valuable insights into the evolving landscape of this technology.

Understanding Additive Manufacturing Basics

At its core, additive manufacturing refers to the process of creating three-dimensional objects by adding material layer by layer, based on a digital model. Unlike traditional manufacturing methods that often involve cutting away material (subtractive manufacturing), this approach is more efficient and can produce complex shapes that would be difficult or impossible to make otherwise.

The process starts with a 3D model, usually designed in computer-aided design (CAD) software. This digital file is then sliced into thin horizontal layers, which the printer uses as a blueprint to build the object from the bottom up. The result is a physical item that matches the original design with impressive accuracy.

Key Types of 3D Printing Methods

There are several main types of 3D printing, each with its own strengths and ideal use cases. Here’s a look at the most common technologies:

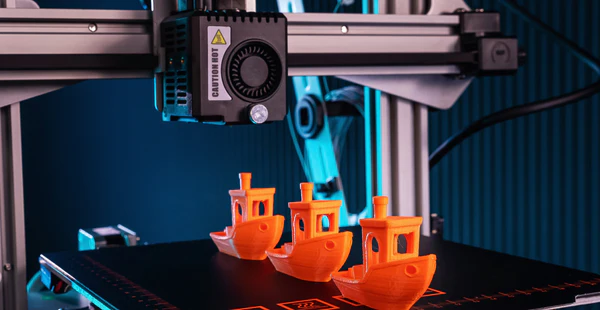

- Fused Deposition Modeling (FDM): This is the most widely used method for home and hobbyist printers. It works by extruding melted plastic filament through a heated nozzle, building up the object layer by layer.

- Stereolithography (SLA): SLA printers use a laser to cure liquid resin into solid layers. This method is known for producing highly detailed and smooth objects, making it popular for prototypes and models.

- Selective Laser Sintering (SLS): SLS uses a laser to fuse powdered materials (like nylon or metal) together. It’s often used for industrial applications due to its strength and versatility.

Each technique has unique advantages, so choosing the right one depends on your project’s requirements, budget, and desired material properties.

Materials Used in 3D Printing

The choice of material is a key factor in any 3D printing project. Here are some of the most common options:

- PLA (Polylactic Acid): A biodegradable plastic derived from renewable resources, PLA is easy to print and ideal for beginners.

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength and durability, ABS is used for functional parts but requires higher printing temperatures.

- Resins: Used in SLA and similar printers, resins can produce highly detailed and smooth surfaces, making them suitable for jewelry, dental models, and miniatures.

- Metals: Industrial printers can use powdered metals like titanium, stainless steel, or aluminum for creating strong, functional parts.

- Nylon and Composites: These materials offer flexibility and toughness, often used in engineering applications.

The right material depends on the intended use of the object, required strength, flexibility, and finish.

How the 3D Printing Process Works

To better understand 3D printing technology explained, it’s helpful to break down the process into clear steps:

- Design: Create or download a 3D model using CAD software or online repositories.

- Slicing: Convert the model into thin layers using slicing software, which generates instructions for the printer.

- Printing: The machine follows these instructions, depositing or curing material layer by layer until the object is complete.

- Post-Processing: Remove supports, sand, or finish the printed item as needed for the final application.

This workflow allows for rapid prototyping, customization, and even small-scale manufacturing, all from a desktop setup.

Applications and Benefits of Additive Manufacturing

The uses for this technology are expanding rapidly across many industries. Some of the most notable applications include:

- Prototyping: Engineers and designers can quickly create prototypes to test form, fit, and function before moving to mass production.

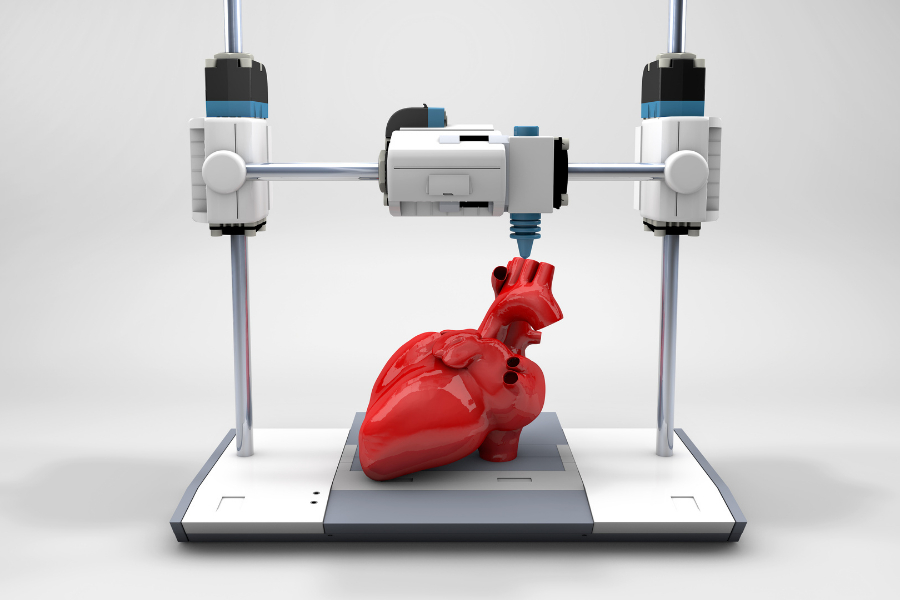

- Medical Devices: Custom prosthetics, dental implants, and even surgical models can be produced with high precision.

- Education: Schools and universities use 3D printers to teach design, engineering, and problem-solving skills.

- Manufacturing: Small-batch production and on-demand manufacturing reduce waste and inventory costs.

- Art and Jewelry: Artists and jewelers leverage the ability to create intricate, one-of-a-kind pieces.

The main advantages include customization, reduced material waste, and the ability to produce complex geometries that traditional methods can’t match.

Getting Started with Your First 3D Printer

If you’re ready to try this technology for yourself, here are some steps to help you begin:

- Choose a Printer: Decide between FDM and resin-based models based on your needs and budget.

- Find or Design Models: Download free files from online libraries, or use CAD software to create your own.

- Learn the Basics: Start with simple projects to get comfortable with your machine and materials.

- Experiment: Try different settings, materials, and designs to expand your skills.

With patience and practice, you’ll be able to produce everything from practical tools to decorative objects, all from your desktop.

Frequently Asked Questions

What Is the Difference Between FDM and Resin 3D Printers?

FDM printers use thermoplastic filaments that are melted and extruded through a nozzle to build objects layer by layer. Resin printers, such as SLA or DLP, use liquid resin cured by light to create highly detailed prints. FDM is generally easier for beginners, while resin offers finer detail and smoother surfaces.

Is 3D Printing Expensive to Start?

Entry-level FDM printers are now quite affordable, with many models available for a few hundred dollars. Resin printers are slightly more expensive and require additional safety precautions. Material costs depend on the type and quality, but basic filaments like PLA are budget-friendly for most users.

What Can I Make with a 3D Printer?

You can create a wide range of items, including prototypes, replacement parts, toys, tools, art, and educational models. The possibilities are only limited by your imagination and the capabilities of your printer.