The world of 3D printing materials is vast and constantly evolving, offering creators, engineers, and hobbyists a wide range of options for bringing digital designs into the physical world. From plastics and resins to metals and composites, each material brings unique properties, benefits, and limitations to the table. Understanding the landscape of available materials is essential for choosing the right one for your project—whether you’re building prototypes, functional parts, or artistic models.

This guide provides a comprehensive look at the most popular materials used in 3D printing, exploring their characteristics, advantages, and potential drawbacks. By the end, you’ll have a clearer sense of which options align best with your needs and how to make informed decisions for your next print.

If you’re just starting out, you may also find it helpful to review our 3D printer setup for beginners guide, which covers essential steps for getting your first machine up and running.

Understanding the Basics of 3D Printing Materials

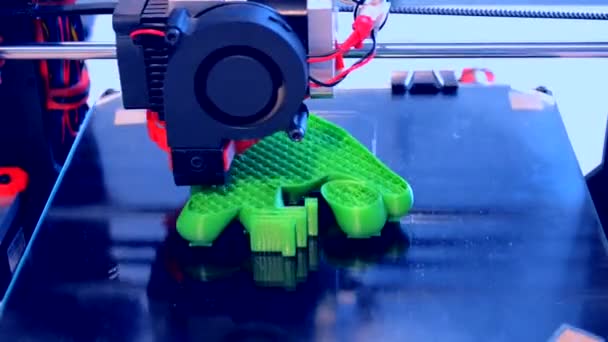

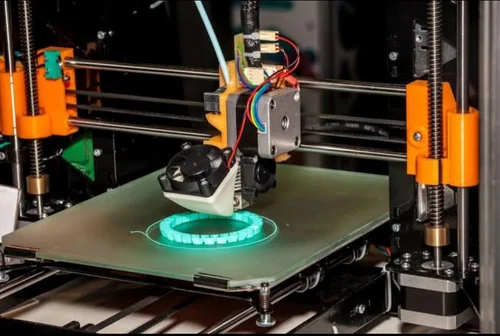

Before diving into specific material types, it’s important to understand how different 3D printing technologies influence material choice. The most common methods—Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS)—each require compatible materials. For example, FDM printers primarily use thermoplastic filaments, while SLA machines rely on liquid resins. The application, required strength, finish, and budget all play a role in selecting the right material.

Common Plastics: PLA, ABS, and PETG

Thermoplastics are the most widely used materials in desktop 3D printing, especially for FDM printers. Let’s examine three of the most popular options:

- PLA (Polylactic Acid): Known for its ease of use, low printing temperature, and biodegradability. PLA is ideal for beginners and for models that don’t need to withstand high stress or heat. However, it’s less durable and heat-resistant than other plastics.

- ABS (Acrylonitrile Butadiene Styrene): Offers greater strength and heat resistance than PLA. It’s suitable for functional parts and prototypes but can be more challenging to print due to warping and the need for a heated bed.

- PETG (Polyethylene Terephthalate Glycol): Combines the ease of PLA with some of the strength and flexibility of ABS. PETG is food-safe, less prone to warping, and offers good chemical resistance.

For a deeper dive into how PLA and ABS compare, check out our detailed PLA vs ABS comparison article.

Resins for SLA and DLP Printing

Photopolymer resins are used in SLA and DLP printers, offering high detail and smooth surface finishes. These materials are popular for jewelry, dental models, and miniatures. The main types include:

- Standard Resin: Delivers excellent detail and a smooth finish, but can be brittle and less durable than thermoplastics.

- Tough and Flexible Resins: Formulated to mimic the properties of ABS or rubber, these resins are better for functional parts.

- Specialty Resins: Includes castable, dental, and biocompatible resins for specific industrial or medical applications.

While resins offer superior resolution, they often require post-processing (washing and curing) and can be more expensive. Safety precautions are also necessary, as uncured resin can be hazardous.

Advanced and Composite Materials

As the technology matures, more advanced 3D printing material options are becoming accessible. These include:

- Nylon: Strong, flexible, and wear-resistant, nylon is suitable for mechanical parts and functional prototypes. It can absorb moisture, so proper storage is important.

- TPU (Thermoplastic Polyurethane): A flexible filament ideal for parts that need to bend or compress, such as phone cases or gaskets.

- Composites: Filaments infused with carbon fiber, glass, or wood particles offer enhanced strength, stiffness, or aesthetic qualities. These materials may require hardened nozzles due to their abrasive nature.

- Metals: Industrial printers can use powdered metals like stainless steel, titanium, or aluminum, enabling the creation of strong, functional metal parts. These processes are more expensive and complex, typically reserved for professional environments.

Comparing Pros and Cons of Popular 3D Printing Materials

| Material | Advantages | Drawbacks |

|---|---|---|

| PLA | Easy to print, biodegradable, low warping | Low heat resistance, brittle |

| ABS | Strong, durable, heat-resistant | Prone to warping, emits fumes, requires heated bed |

| PETG | Good strength, flexible, food-safe | Can string, less rigid than ABS |

| Resin | High detail, smooth finish | Brittle, requires post-processing, safety concerns |

| Nylon | Strong, flexible, wear-resistant | Absorbs moisture, more difficult to print |

| TPU | Flexible, impact-resistant | Challenging to print, slow speeds |

| Composites | Enhanced strength or aesthetics | Abrasive, may require special hardware |

| Metals | Exceptional strength, industrial use | Expensive, complex process |

Choosing the Right Material for Your Project

Selecting the best material depends on your project’s requirements. Consider the following factors:

- Strength and Durability: For functional parts, ABS, PETG, or nylon are good choices.

- Detail and Finish: Resin-based materials excel for intricate models and smooth surfaces.

- Flexibility: TPU or flexible resins are ideal for parts that need to bend.

- Ease of Use: PLA is recommended for beginners due to its forgiving nature.

- Budget and Availability: Standard filaments like PLA and ABS are widely available and affordable, while specialty materials may cost more.

For those new to desktop fabrication, our how to start 3D printing at home resource covers the basics of getting started with your first projects.

Tips for Successful Printing with Different Materials

Each material comes with its own set of best practices. Here are some general tips to help you get the most out of your chosen filament or resin:

- Storage: Keep filaments dry and away from humidity, especially nylon and PVA, which absorb moisture easily.

- Printer Settings: Adjust temperature, print speed, and bed adhesion based on the manufacturer’s recommendations for each material.

- Ventilation: Print ABS and some resins in well-ventilated areas to avoid inhaling fumes.

- Post-Processing: Some materials, like resin prints, require additional steps such as washing and UV curing for optimal results.

- Troubleshooting: If you encounter issues, our 3D printing troubleshooting guide can help resolve common problems.

Further Learning and Resources

The field of additive manufacturing is rapidly advancing, with new materials and techniques emerging regularly. To deepen your understanding of how these technologies work, consider reading this in-depth explanation of 3D printing mechanisms and real-world examples.

Avoiding mistakes is also key to successful prints. Review our list of common 3D printing mistakes to help ensure smoother results.

Frequently Asked Questions

What is the most beginner-friendly 3D printing material?

PLA is widely considered the easiest material for newcomers. It prints at lower temperatures, has minimal warping, and does not require a heated bed. Its ease of use makes it ideal for learning and prototyping.

How do I choose between filament and resin materials?

The choice depends on your printer type and project needs. Filaments like PLA, ABS, and PETG are used in FDM printers and are suitable for functional parts and larger models. Resins, used in SLA/DLP printers, offer higher detail and smoother finishes, making them better for miniatures and intricate designs.

Are there safety concerns with 3D printing materials?

Yes, some materials emit fumes or require handling precautions. ABS and certain resins can release potentially harmful substances, so always print in a well-ventilated area and use gloves when handling uncured resin. Follow all manufacturer safety guidelines.