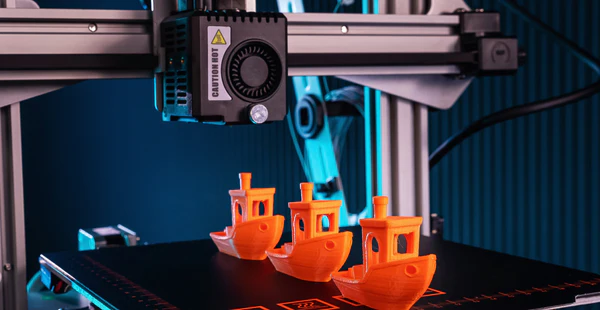

For emerging businesses, rapid prototyping is essential to bring ideas to life, test concepts, and iterate quickly without breaking the bank. 3D printing for startups has transformed the way new ventures approach product development, offering a flexible and affordable alternative to traditional manufacturing processes. By leveraging additive manufacturing, small teams can create functional prototypes, refine designs, and accelerate their path to market—all while keeping costs under control.

This guide explores how additive manufacturing empowers entrepreneurs, highlights practical steps for integrating this technology into your workflow, and provides actionable tips for maximizing value from your prototyping budget. Whether you’re designing hardware, consumer products, or custom components, understanding the benefits and best practices of 3D printing can give your startup a significant edge.

As you explore the possibilities of rapid prototyping, don’t overlook the role of finishing techniques. For example, learning about sanding and finishing 3D prints can help you achieve professional results, even with entry-level printers.

Why Additive Manufacturing Is a Game-Changer for New Businesses

Traditional prototyping methods often require expensive tooling, long lead times, and minimum order quantities that are out of reach for most startups. In contrast, 3D printing for startups enables on-demand production of single units or small batches, reducing both upfront investment and risk. This flexibility allows entrepreneurs to iterate quickly, test multiple design variations, and respond to feedback without waiting weeks or months for new parts.

- Lower costs: No need for costly molds or dies; print only what you need.

- Faster turnaround: Move from CAD file to physical prototype in hours or days.

- Design freedom: Create complex geometries that are difficult or impossible with subtractive methods.

- Customization: Easily modify designs for different use cases or customer requirements.

Choosing the Right 3D Printing Technology for Your Startup

There are several types of 3D printers suitable for prototyping, each with its own strengths and limitations. The most common technologies for startups include Fused Deposition Modeling (FDM) and Stereolithography (SLA). Understanding the differences can help you select the best fit for your needs.

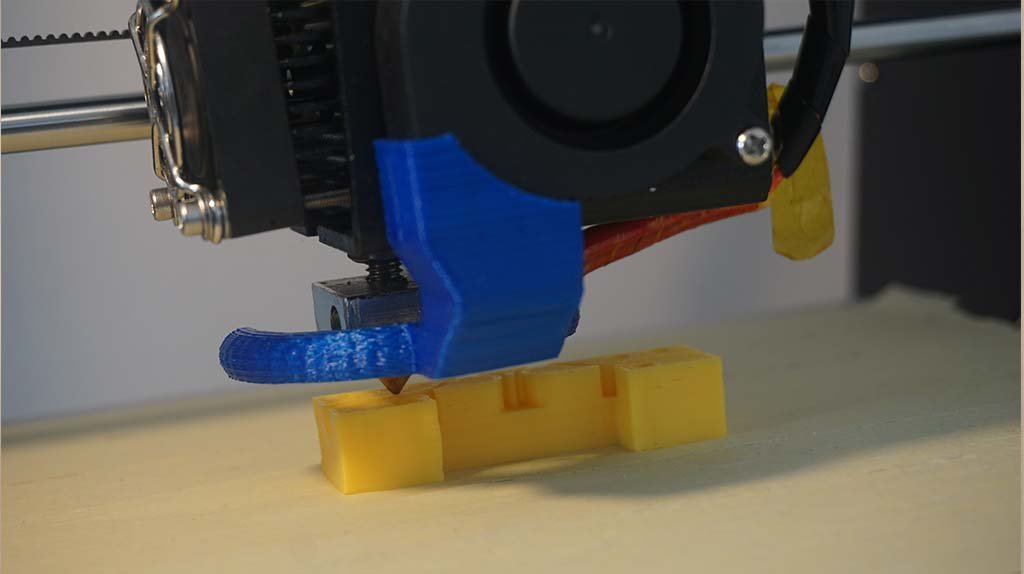

FDM: Affordable and Versatile

Fused Deposition Modeling is the most accessible option for many startups. These printers use thermoplastic filaments to build objects layer by layer. FDM machines are affordable, easy to maintain, and compatible with a wide range of materials, including PLA, ABS, and PETG. They are ideal for functional prototypes, enclosures, and mechanical parts.

SLA: High Detail and Smooth Surfaces

Stereolithography uses liquid resin cured by a laser to produce highly detailed parts with smooth finishes. While SLA printers are generally more expensive than FDM, they excel at creating prototypes that require fine features or a polished appearance. This makes them suitable for product design, dental models, and intricate components.

Optimizing Your Prototyping Workflow

To get the most from 3D printing for startups, it’s important to establish an efficient workflow from design to finished part. Here are some practical steps to streamline your process:

- Start with a clear CAD model: Use reliable design software to create accurate digital models. Consider the limitations of your chosen printing technology, such as minimum wall thickness and overhangs.

- Choose the right material: Select filament or resin based on the prototype’s intended use. For example, PLA is easy to print and biodegradable, while ABS offers greater strength and heat resistance.

- Optimize print settings: Adjust layer height, infill density, and support structures to balance speed, strength, and material usage. For guidance on infill choices, see this resource on 3D printing infill patterns.

- Post-processing: After printing, remove supports and improve surface quality. Techniques like sanding, painting, or chemical smoothing can enhance the look and feel of your prototypes. For more on this, explore tips on post processing 3D prints.

Managing Costs and Maximizing Value

Keeping expenses in check is a top priority for any new business. Here are some strategies to ensure your prototyping remains budget-friendly:

- Print only what you need: Avoid unnecessary iterations by reviewing designs thoroughly before printing.

- Batch small parts: Combine multiple components in a single print job to save time and material.

- Maintain your equipment: Regular cleaning and calibration prevent failed prints and wasted resources.

- Leverage online resources: Platforms like the comprehensive 3D printing guide from Xometry offer valuable tips for optimizing your process.

- Prevent common issues: Learn how to avoid problems like warping by following best practices, such as those shared in this article on how to prevent warping in prints.

Best Practices for Quality and Efficiency

To ensure your prototypes meet both functional and aesthetic requirements, consider these additional tips:

- Test and iterate: Use feedback from each prototype to refine your design. Rapid iteration is one of the biggest advantages of additive manufacturing.

- Document your process: Keep notes on print settings, materials, and outcomes to improve future results.

- Finish your parts: Techniques such as painting 3D printed models can give your prototypes a professional appearance for presentations or investor pitches.

- Stay updated: The world of 3D printing evolves quickly. Follow industry news and experiment with new materials or techniques as they become available.

Frequently Asked Questions

How much does it cost to start prototyping with 3D printing?

Entry-level FDM printers suitable for startups can be found for a few hundred dollars, while resin-based SLA machines typically start at a higher price point. Material costs are generally low, with most filaments and resins priced affordably for small-batch production. Factoring in maintenance and occasional upgrades, most new businesses can begin prototyping for less than the cost of a single traditional mold.

What are the main limitations of 3D printing for early-stage companies?

While additive manufacturing offers flexibility and speed, it does have some constraints. Print size is limited by the build volume of your machine, and certain geometries may require supports or post-processing. Additionally, some materials may not provide the strength or durability needed for final products, making 3D printing best suited for prototyping and low-volume production.

Can 3D printed prototypes be used for functional testing?

Yes, many startups use printed parts for fit, form, and even basic functional testing. By selecting the right material and print settings, you can produce prototypes that closely mimic the properties of final products. However, for demanding applications or regulatory compliance, additional testing and validation may be necessary.

How can startups improve the surface finish of their 3D printed parts?

Surface quality can be enhanced through post-processing methods such as sanding, priming, and painting. For more detailed guidance, refer to resources on sanding and finishing 3D prints and post processing 3D prints.

Conclusion

Embracing 3D printing for startups provides a powerful, cost-effective pathway to rapid prototyping and product innovation. By choosing the right technology, optimizing your workflow, and applying best practices, your team can accelerate development cycles, reduce expenses, and bring better products to market faster. As additive manufacturing continues to evolve, staying informed and adaptable will ensure your business remains competitive and ready for growth.