The landscape of manufacturing is rapidly evolving, with 3D printing automation trends driving a new era of efficiency, scalability, and innovation. As businesses seek smarter, more adaptive production methods, automated additive manufacturing is emerging as a key enabler of digital transformation. From streamlined workflows to intelligent monitoring, automation is reshaping how products are designed, produced, and delivered.

This article explores the most significant developments in automated 3D printing, how they are impacting smart factories, and what manufacturers can expect as these technologies mature. Whether you are new to additive manufacturing or looking to optimize your existing workflow, understanding these trends is essential for staying competitive in a rapidly changing market.

For those interested in mastering advanced techniques, understanding printing complex geometries can help unlock the full potential of automated 3D printing systems.

Key Drivers Behind Automated Additive Manufacturing

The push for automation in 3D printing is fueled by several factors. Manufacturers are under pressure to reduce costs, accelerate time-to-market, and maintain consistent quality. Automation addresses these needs by minimizing manual intervention, reducing errors, and enabling continuous production.

- Labor shortages and rising wages make automated systems attractive for maintaining productivity.

- Demand for mass customization requires flexible, scalable production lines that can adapt quickly to new designs.

- Quality assurance benefits from real-time monitoring and data-driven process control, reducing waste and rework.

- Integration with Industry 4.0 initiatives enables seamless data exchange between machines, software, and enterprise systems.

Emerging Technologies Shaping 3D Printing Automation

Several technological advances are propelling the evolution of automated additive manufacturing. These innovations are making it easier to scale up production, ensure repeatability, and connect 3D printers with the broader digital ecosystem.

Automated Material Handling and Post-Processing

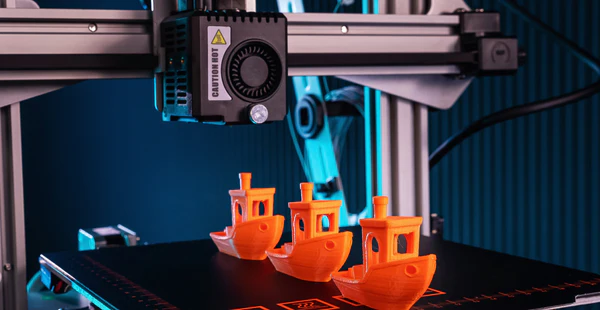

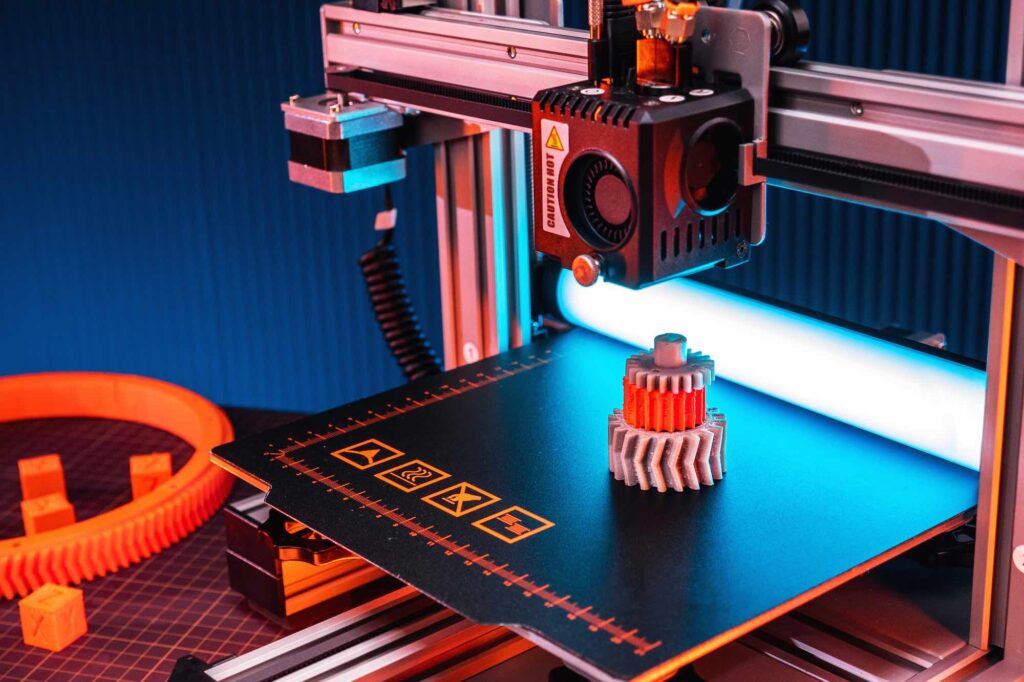

One of the most significant 3D printing automation trends is the integration of robotic arms and conveyor systems for material loading, part removal, and post-processing. Automated handling reduces downtime between print jobs and ensures consistent part quality.

For example, some industrial 3D printers now feature robotic part removal, allowing for true lights-out manufacturing. This means printers can operate unattended overnight or during weekends, maximizing equipment utilization.

Smart Monitoring and Predictive Maintenance

Intelligent sensors and IoT connectivity are transforming how 3D printers are managed. Real-time monitoring allows operators to track print progress, detect anomalies, and intervene before issues escalate. Predictive maintenance algorithms analyze machine data to forecast component wear and schedule service, reducing unplanned downtime.

These capabilities are particularly valuable in high-volume production environments, where even minor disruptions can have significant cost implications.

Software Integration and Workflow Automation

Modern additive manufacturing platforms increasingly offer end-to-end workflow automation. From design file preparation to print job scheduling and quality inspection, software tools are streamlining every step of the process. This reduces manual touchpoints and ensures that each part meets precise specifications.

For those new to the field, learning about 3D printing file formats explained can help ensure compatibility and efficiency in automated workflows.

How Automation Is Transforming Smart Factories

The adoption of automated 3D printing is a cornerstone of the smart factory concept. By connecting printers, robots, and software platforms, manufacturers can achieve unprecedented levels of agility and responsiveness.

- On-demand production becomes feasible, allowing companies to respond quickly to changing customer needs.

- Inventory costs are reduced, as parts can be printed as needed rather than stored in bulk.

- Customization is simplified, enabling the creation of unique products without retooling or manual intervention.

- Data-driven optimization helps identify bottlenecks and continuously improve production efficiency.

As more manufacturers embrace these technologies, the role of automation in additive manufacturing will only grow. The ability to scale production, maintain quality, and reduce costs is a compelling value proposition for industries ranging from aerospace to healthcare.

Practical Steps to Implement Automation in Additive Manufacturing

Transitioning to automated 3D printing requires careful planning and investment. Here are some practical steps to get started:

- Assess current workflows: Identify manual tasks that can be automated, such as material loading, part removal, or quality inspection.

- Invest in compatible hardware: Choose 3D printers and accessories designed for integration with automation systems.

- Adopt workflow software: Implement platforms that support print job scheduling, remote monitoring, and data analytics.

- Train your team: Ensure staff are familiar with both the hardware and software aspects of automated production.

- Start small, then scale: Pilot automation on a limited number of machines before expanding to full production.

For those designing parts for automated production, reviewing how to design for 3D printing can help avoid common pitfalls and maximize print success.

Benefits and Challenges of Automation in 3D Printing

The advantages of automated additive manufacturing are clear, but there are also challenges to consider.

| Benefits | Challenges |

|---|---|

|

|

Overcoming these challenges often requires collaboration between equipment vendors, software providers, and in-house engineering teams. Staying informed about the latest 3D printing automation trends is crucial for making strategic decisions.

If you’re interested in the basics of additive manufacturing, this introduction to 3D printing provides a helpful overview of the technology and its applications.

Looking Ahead: The Next Wave of Automated Additive Manufacturing

As technology continues to advance, the future of automated 3D printing looks promising. Artificial intelligence, machine learning, and advanced robotics are poised to further enhance production capabilities. We can expect smarter systems that optimize print parameters in real time, self-healing machines that minimize downtime, and even greater integration with supply chain and logistics platforms.

For designers and engineers, keeping up with 3D modeling tips for printing and CAD for 3D printing beginners will be essential as automation becomes more prevalent in the industry.

Ultimately, those who embrace these changes will be well-positioned to lead in the era of smart manufacturing, delivering innovative products with speed, precision, and flexibility.

Frequently Asked Questions

What are the main benefits of automating 3D printing processes?

Automation in additive manufacturing delivers increased productivity, consistent part quality, and reduced labor costs. It also enables continuous production, minimizes human error, and allows for rapid scaling of operations.

How does automation impact the cost of 3D printing?

While there is an initial investment in automated equipment and software, the long-term savings from reduced labor, fewer errors, and higher throughput often outweigh the upfront costs. Automated systems also help lower per-part costs by maximizing machine utilization.

What industries benefit most from automated additive manufacturing?

Sectors such as aerospace, automotive, healthcare, and consumer goods are leading adopters of automated 3D printing. These industries require high precision, customization, and the ability to scale production efficiently.